Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/PPGI

1. Detailed Specifications:

| Product | Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/ |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application:

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

3. Image:

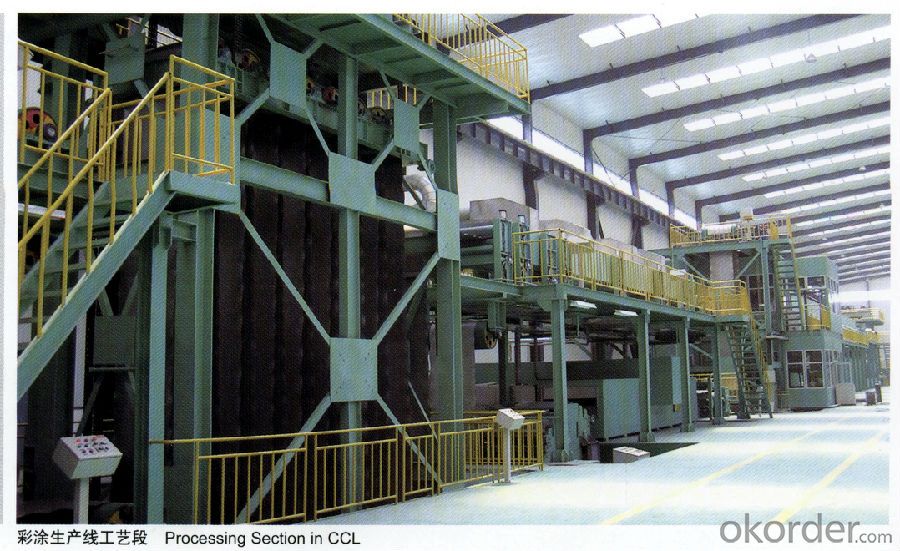

production Line:

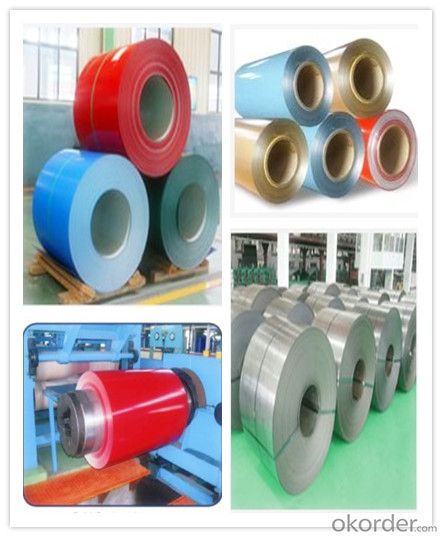

production show:

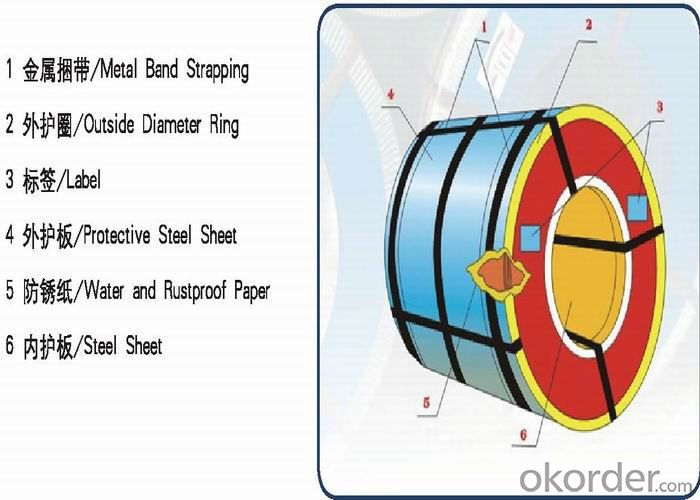

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.RFQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q:How are steel coils used in the production of industrial storage tanks?

- Steel coils are commonly used in the production of industrial storage tanks due to their superior strength and durability. These coils are typically made from high-quality steel that is rolled into a coil shape, allowing for easy transportation and handling. In the production process, steel coils are first uncoiled and flattened to create sheets of steel. These sheets are then cut and formed into the desired shape and size for the storage tank. The steel sheets are welded or bolted together to create the tank's body, which is designed to withstand high pressure and heavy loads. The use of steel coils in the production of industrial storage tanks offers several advantages. Firstly, the strength and durability of steel ensure that the tanks can withstand harsh conditions and are resistant to corrosion. This is particularly important for storage tanks that may contain corrosive substances or be exposed to harsh environments. Additionally, the flexibility of steel coils allows for customization of the tank's design and size. This is particularly beneficial in industries where storage requirements can vary significantly, such as the oil and gas industry. Steel coils can be easily cut and formed into various shapes and sizes, enabling the production of storage tanks that meet specific storage needs. Furthermore, steel coils can be easily transported and stored, making them a cost-effective choice for the production of industrial storage tanks. The coils can be efficiently transported to the manufacturing facility, reducing transportation costs and logistical complexities. Overall, steel coils play a crucial role in the production of industrial storage tanks by providing strength, durability, and customization options. Their use ensures that the tanks can safely store and protect various substances, making them essential for a wide range of industries.

- Q:For my homework we have to fill out a table, but I cannot find some basic uses of these types of steel anywhere:Low carbon steel (iron mixed with lt;0.25% carbon)High carbon steel (iron mixed with lt;1.5% carbon)Stainless steel (iron mixed with nickle an chromium)Titanium steel (iron mixed with titanium)Manganese steel (iron mixed with manganese) Thanks :)

- Low okorder / You say you cannot find there uses anywhere. These all came up using the simplest of web searches. You really need to have a word with your IT teacher as clearly you are not doing basic searches properly.

- Q:In pounds per square inch what is the tensile strength of strong steel?

- The term tensile strength refers to the amount of tensile (stretching) stress a material can withstand before breaking or failing. The ultimate tensile strength of a material is calculated by dividing the area of the material tested (the cross section) by the stress placed on the material, generally expressed in terms of pounds or tons per square inch of material. Tensile strength is an important measure of a material's ability to perform in an application, and the measurement is widely used when describing the properties of metals and alloys.

- Q:What is the process of pickling and oiling steel coils?

- To ensure the quality and protection of steel coils, a series of steps are undertaken in the process of pickling and oiling. The first step involves pickling, wherein impurities and scale are removed from the surface of the steel coil. This is achieved by immersing the coil in an acid bath, such as hydrochloric acid or sulfuric acid, which effectively dissolves any oxides, rust, or contaminants present on the surface. This step is critical as it readies the steel for further processing and safeguards against potential defects or corrosion. Following pickling, the steel coils are rinsed with water to eliminate any residual acid and then dried. Once they are clean and dry, a layer of oil is applied to provide temporary corrosion protection and lubrication during subsequent handling and transport. The oil coating acts as a barrier, preventing rusting or oxidation before the steel undergoes further processing or is utilized in various applications. The oiling process can be executed through various methods. One common approach is to apply the oil using a roller or brush, ensuring an even coating across the entire surface of the coil. Alternatively, the coils can be passed through a bath or spray chamber where the oil is administered. The choice of oil depends on the specific requirements of the steel and its intended use, with options ranging from mineral oil and synthetic oils to specialized rust-preventive coatings. Once the oiling process is complete, the steel coils are typically stacked, wrapped, or packaged for storage or transportation. It is crucial to handle the coils with care to avoid damaging the oil coating and compromising the corrosion protection it provides. Overall, the pickling and oiling of steel coils are indispensable steps in the steel manufacturing process. They ensure the quality, cleanliness, and protection of the steel, thereby prolonging its lifespan and enhancing its performance in various applications.

- Q:All the appliances in my kitchen are stainless steel, and I hate how they look becuase every time I wash them they are full of streaks. Is there a good cleaner made for stainless steel that won't leave streaks?

- I love Zep Stainless Steel Cleaner. It doesn't leave streaks, it is a foam on easy application and it leaves a protective coating that resists fingerprints and food from sticking on the surface. I even use it on my stainless cooktop and it gets off burned on food, too. I get it at the Home Depot and a big can lasts a long time.

- Q:What are the different methods of storing steel coils?

- There are several methods of storing steel coils, depending on the specific requirements and constraints of the storage facility. Some of the commonly used methods include: 1. Stack storage: This method involves stacking the steel coils on top of each other in a stable manner. It is a cost-effective method, as it maximizes the use of vertical space. However, it requires careful stacking to ensure stability and prevent damage to the coils. 2. Block stacking: In this method, steel coils are arranged in blocks, with each coil placed directly on top of another. The blocks are then stacked to maximize the use of space. This method provides stability and allows for easy access to individual coils. However, it may require the use of additional equipment such as coil cradles or coil saddles to prevent damage. 3. Coil cradles: Coil cradles are specialized racks or frames that are designed to hold steel coils horizontally. They provide support and prevent the coils from rolling or shifting. This method is particularly suitable for smaller coils or when quick access to individual coils is required. 4. Coil saddles: Coil saddles are U-shaped frames that are specifically designed to hold and support steel coils vertically. They are often used in conjunction with block stacking or stack storage methods. Coil saddles provide stability and prevent the coils from rolling or collapsing. 5. Coil racks: Coil racks are steel structures that are designed to hold multiple coils in an organized manner. They may have several levels or tiers, allowing for efficient use of space. Coil racks are typically used for larger coils and can be customized to accommodate specific coil dimensions. 6. Automated storage systems: In large-scale storage facilities, automated systems such as coil cranes or coil carousels may be employed. These systems use mechanical devices to transport and store steel coils, allowing for efficient and fast retrieval when needed. They are particularly useful in high-volume operations where frequent coil handling is required. It is essential to consider factors such as coil size, weight, accessibility, and environmental conditions when determining the most suitable method of storing steel coils. Additionally, proper handling, labeling, and regular inspections are crucial to ensure the integrity and longevity of the stored coils.

- Q:How are steel coils used in the manufacturing of marine equipment?

- Steel coils are used in the manufacturing of marine equipment as they provide the necessary strength and durability required for the construction of various components such as ship hulls, bulkheads, decks, and structural supports. These coils are typically used as raw material for cutting, shaping, and welding into the required shapes and sizes, ensuring the marine equipment can withstand the harsh conditions of the sea and maintain its structural integrity.

- Q:The Chinese invented the windmill long before the 1800's, but I cannot find anywhere who invented the steel windmill, I believe it was in the 1800'sIf you know the answer that'd be great!And also if you could find the date it was patented? Thanks SO much!

- The Steel Eclipse Type WG was the first of several self-oiling steel windmills marketed by Fairbanks, Morse, and Company after they became the distributor of all the Eclipse mills about the start of the 20th Century. It has the more important distinction of having been the only widely distributed worm-gear mill in the history of American windmill manufacture. Produced from about 1926 to the mid-1930's, the Steel Eclipse remains in the field today in considerable number in most parts of the country. Hope this helps!

- Q:I am trying to make a homemade fender eliminator for my motorcycle and the instructions from the site I found said to use 22 gage weld steel. I went to lowes and all they had was 26 gage sheet metal. What is the difference between the two? Is weld steel less flexible?

- 22 gauge steel is thicker than 26 gauge steel. They are saying weld steel but actually mean black steel(mild steel) not galvanized. You will be hard pressed to find 22 gauge black steel unless you go to a local sheet metal shop or go online to find it. The big box stores most likely will not carry 22 ga. black steel. Also not many sheet metal shops don't carry sheet metal that thin unless it is galvanized. Try searching online for 22 gauge mild steel, or black steel, or let your fingers do the walking and try a couple of local metal or welding shops.

- Q:What are the common certifications required for steel coils?

- The common certifications required for steel coils include ISO 9001 (Quality Management System), ISO 14001 (Environmental Management System), and OHSAS 18001 (Occupational Health and Safety Management System). Additionally, certifications like ASTM (American Society for Testing and Materials) and EN (European Norm) standards are important for ensuring the quality and compliance of steel coils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords