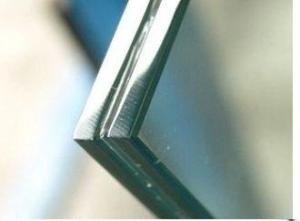

Coated laminated glass 8+1.14SGP+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q:New glass features

- plate glass Flat glass is not processed by other flat glass products, also known as white glass or clean glass. According to the production method is different, can be divided into ordinary flat glass and float glass. Flat glass is the largest in the building glass, the most used one, mainly for doors and windows, from lighting, enclosure, insulation, sound insulation and other effects, but also further processed into other technical glass of the original film. Flat glass according to its use can be divided into window glass and decorative glass. According to the national standard "ordinary flat glass" and "float glass" provisions, the glass according to its thickness can be divided into the following specifications: In accordance with national standards, flat glass according to its appearance quality classification grading, ordinary flat glass is divided into superior products, first-class goods and second-class three grades. Float glass is divided into three grades: superior grade, first grade and qualified product. Flat glass use has two aspects: 3 ~ 5mm flat glass is generally used for doors and windows of the lighting, 8 ~ 12mm flat glass can be used to cut off. Another important use is as the original film of tempered, interlayer, coated, hollow and other glass.

- Q:What parts of the building curtain wall project?

- The construction materials include: project approval documents (preparation documents and management documents), supervision documents, construction documents (construction management records, design changes, product quality certification documents, engineering inspection data, construction records, safety and functional testing) Construction plans, audio and video information, project bidding information, project settlement information, project safety management information, and the relevant units of the documents.

- Q:Automotive glass insulation film paste technology

- The most basic tools are roasted guns, watering cans, foil special agent (or detergent water), water scraper, paste scraper, deerskin, Huju, a knife, each model is not the same paste method is not the same , But there is a common point of glass must be cleaned, preferably in the clean film between the operation.

- Q:Is there a standard for frosted glass in the bathroom?

- Frosted glass is generally not steel, this should pay attention

- Q:Tempered glass and ordinary glass technology and raw materials What is the difference in detail Thank you

- The production process of the glass is: raw material crushing, sieving, weighing, mixing, high temperature (1600 degrees) melting into glass liquid, glass liquid homogenization cooling forming, cutting, annealing, cooling, inspection, packaging. The main raw materials are: quartz sand or sandstone, feldspar, soda ash, limestone, dolomite, in addition to soda ash are ore raw materials, need to break into the appropriate size. Tempered glass is a reusable product of ordinary glass. The main components of its glass is silica, calcium oxide and sodium oxide, so called sodium silicate glass. There are two ways to temper glass, physical steel (air-cooled steel) and chemical steel. Tempered glass is used in the chemical steel method. The principle is to use the "head" of the larger potassium ions to replace the glass surface "head" smaller sodium ions, making the glass surface was tensioned, that is, the formation of compressive stress, so that the glass has a very high impact resistance Increased by 5 times). Physical tempered architectural glass also makes the glass surface compressive.

- Q:China insulation film which company is better? Is it really effective?

- Must have some, after the home posted at noon obviously did not feel so hot, is the China Wu Zhuo glass film company posted

- Q:Is there really a decelerating glass?

- The so-called slow-down glass is the use of the glass surface of the lens effect to reduce the visual sense of speed, so that people feel the speed reduced. The front windshield of the car uses this principle to reduce the deformation of both sides of the scene, reducing the visual displacement of the lateral scene, and the front of the scene is basically direct access, giving the impression that both sides of the scene moving slower.

- Q:Any1 know wat that big glass building is next to City Hall in Cork???

- i think its the new building for doing tax,bin charges etc. my friend thinks its a libary and i heard some1 else say it was part of the fire station so who knows....go in there someday thats the quickest way to find out!!!!!!!

- Q:Building decoration commonly used varieties of light and heat glass

- Glass products are decorative mirror, glass brocade, glass tiles, glass hollow brick and so on.

- Q:How is the sun room insulated?

- Awning. Shade cloth Shade sun foil. 4. Shade bamboo curtain. Folding awning advantages: winter removed, the sun came in. Disadvantages: trouble, high cost. Shade cloth advantages: free to install. Disadvantages: with magnetic buckle, asked the sun room material, metal class. Shade sun foil Advantages: paste up do not have to back and forth is not cumbersome. Disadvantages: a little light block, the room was dark. Shade bamboo curtain advantages: low cost, simple, the original ecology. Disadvantages: ash, bad care.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated laminated glass 8+1.14SGP+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords