Coated laminated glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

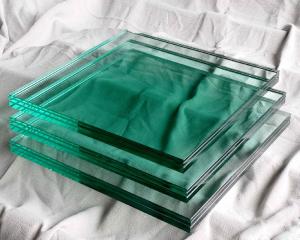

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

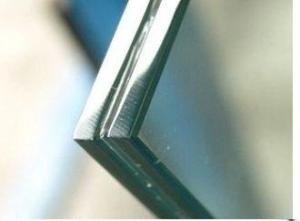

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q:I was on the site repair house, the building walls are all glass, building materials have been shipped to, but due to improper protection, some glass scratches, and whether the equipment can repair these architectural glass scratches?

- Architectural glass and general glass, the scratches appear can be repaired. Like you such a large-scale repair the best use of the first grinding and then polished way to repair, so efficient and efficient repair, you can perfectly repair all kinds of scratches.

- Q:Sound insulation glass how much money a square

- According to the level of external noise, using our different sound insulation glass combination program, the general indoor can achieve the highest national quiet standard (0 level noise standard). In a large number of practical installation and application process, different degrees of outdoor noise by our professional staff of the measurement, analysis, judgment, using the most appropriate combination of sound insulation solutions, can reach 40 dB below, and some areas can even reach 30- 33 dB, the villa's basement is generally 28-32 dB.

- Q:China's well-known foreign glass factory which several

- Glass is a big industry, there are many subdivisions, such as flat glass, architectural glass, medical glass, ultra-white glass, etc., China Southern Glass Group Co., Ltd The Group is headquartered in Shekou, OKorder, with subsidiaries in Australia, the Middle East and Hong Kong. The Group's top ten production and raw materials bases are located in OKorder, Dongguan, Guangzhou, Chengdu, Tianjin, Langfang, Wujiang, Yichang, Hainan Wenchang, Sichuan Jiangyou and other places

- Q:What are the types of glass?

- Hot-melt glass, also known as crystal three-dimensional art glass, is currently beginning in the decoration industry in the emergence of a new family. Hot-melt glass from Western countries, in recent years to enter our market. Previously, China's market are foreign products, Glass manufacturers to introduce foreign hot melt furnace production products. Hot-melt glass with its unique decorative effect as the design unit, the glass processing owners, decorating the owner of the attention of the focus.Film glass across the existing glass form, give full play to the designer and craftsman's artistic conception, the modern or classical Of the art form into the glass, so that the processing of a variety of flat glass bumps, color different artistic effects.

- Q:Curtain wall classification of building curtain wall

- Building curtain wall is composed of supporting structural system and the panel can be relative to the main structure of a certain displacement ability, but does not share the main structure of the load and the role of the building outside the envelope or decorative structure. (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) 3) point support glass curtain wall 2. metal curtain wall 3. stone curtain wall 4. man-made sheet curtain wall 5. combination curtain wall (b) according to the curtain wall construction method classification is divided into: 1. unit curtain wall 2. component curtain wall (three) Double curtain wall 2. Light curtain wall

- Q:Building glass curtain wall VR how to tune material

- Will be a material balloon VRAYMAP Diffuse fixed, transferred to the white, fuzzy 0.98 Subdivision value 5 Refract transferred to white, IOR 1.517 affect shadow selected to Reflect the MAP Panel selection FALLOFF Type election Fresnel Stainless steel blinn replaced by metal Highlight Level 90 The following 70 to 80 reflect the NONE at the midpoint of the MAP panel Election VRAYMAP

- Q:How to distinguish between glass and glass?

- Glass is the ancient Chinese glass on the call, is a narrow glass argument, now refers to the glass is added to a variety of oxide made of colored glass works, whether it is optical glass, flat glass, crystal glass, or borax glass And other materials produced by the works, are known as glass works of art, which can be seen glass is a kind of glass, the scope of the range is much smaller than the glass.

- Q:What is the architectural glass business?

- It is not very good at present, because it is still in the marketing period. A new technology and energy-saving products from the market to promote them to have a certain time. Many consumers are still waiting to see. So that the current business is not how.

- Q:Why is a long time to open plastic glue, why have bubbles.

- Glass is also known as laminated glass. English name Laminated Glass, laminated glass is two or more pieces of float glass intermediate folder with tough PVB (ethylene polymer butyrate) film, by pressing the hot press together as much as possible to discharge the middle of the air, and then put Into the high-pressure steamer within the use of high temperature and pressure will be a small amount of residual air into the film made of. In order to facilitate the higher requirements of customers and designers, can provide a variety of PVB film for customers to choose to see (transparent, white, gray, porcelain white, blue, green, silk screen, etc.). Is not it authentic? One is grouting, One is film, After the species is much better than the former,

- Q:Is there a hmdso residue for the coated silica film?

- 1. Application in hard coatings: cutting tools, molds and wear-resistant corrosion-resistant parts. 2. In the protective coating applications: aircraft engine blades, automotive steel, heat sink and so on. 3. In the field of optical film applications: anti-reflective film, high anti-film, cut-off filter, anti-counterfeiting film. 4. Application in architectural glass: sunlight control film

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Coated laminated glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords