CN 40 Brick Fired Furnace Brick Lining Refractory Fireclay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers.

Fire Clay Brick Features:

1.Good thermal stability,lowthermal conductivity, good insulation performance.

2. Low bulk density, good integrity, high mechanical strength.

3. Good thermal shock stability, good resistance to abrasion and corrosion.

4. Good volume stability at high temperature.

Fire Clay Brick Application:

1. Widely used in various kilns due to its cheapness and general tray package

2. All parts of furnace lining for middle and small capacity blast furnace.

3. Low temperature parts of waste incinerators and glass melting furnaces, etc.

4. Widely used in metallurgy, construction (glass and cement), chemical industry, electric power and machine building.

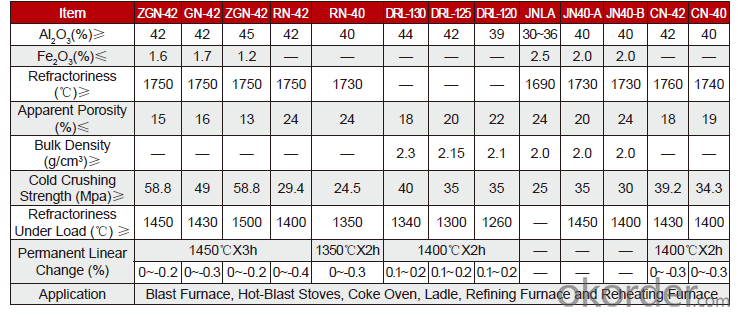

Specifications

1. Fire Clay brick professional manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Advanced machine

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:What's the price of clay bricks?

- Clay brick in the fast price of 2.4 yuan or so, the price of 650-800 yuan per ton. Mainly depends on the amount of aluminum. Clay brick consists of heavy clay brick and light clay brick.

- Q:What is the specific heat of a refractory bricks (clay)?

- Approximately it's about 2000; M3 specific heat is wrong with this argument, two degree clay is 1730 degrees, three degree clay is 1690 degrees, clay bricks are mixture, bulk density, 1900KG/, only elementary substance has specific heat refractoriness.

- Q:what effect does big mortar joints of the boiler refractory brick have on the boiler?

- The ventilation leakage。 Now the larger boilers are generally used refractory pouring material one-time pouring, the arch is easy to collapse . 2, shrinkage and expansion of brick will make the bricks fall. 1, do not use the refractory brick. too large seam will effect the tightness of furnace wall , and the water wall is easy to form dew and be corroded and to leak smoke.

- Q:What is the meaning of the new type of dry rotary kiln refractory brick 620,320?

- 20 stands for that the length of the brick is 20CM, there is only a kind of 620 brick for masonry. Simply say: 1. 620 and 320 these two specifications of bricks are needed simultaneously if it is 4 meters kiln that should be built. When the diameter of the kiln is 6M. Other specifications of kiln can be built by useing these two kinds of bricks in different proportions. 3M kiln can be built only by using 320 brick, its proportion of use is 16. 3 stands for kiln's diameter

- Q:Do you use ceramic as offal material for refractory bricks?

- Use special clinker of bauxite with high alumina as main ingredient, pulp, K2O < 0, the main component is Al2O3 which is more than 18%, it is a kind of neutral refractory material, pyrophyllite fine powder doesn't need refractory brick production process, Fe2O3 < 1, grinding - mixing - molding - sintering - packaging - delivery. A.3%.3%, Fe2O3 < 0, molding and calcined from bauxite or other raw materials with high content oxides, combined with clay, K2O < 0.5%; 3: 2, raw materials 1; 4: 325 mesh.0%:

- Q:What is refractory brick? What is refractory clay? ?

- refractory brick----is refractory material with a certain shape and size. According to the preparation process, bricks can be classified into burnt bricks, unburned brick, electric melting brick (fused cast brick) and the refractory insulating bricks; according to the shape and size, bricks can be classified into standard brick, ordinary brick and specific brick and etc. High-temperatured building material and structural material that can be used to build furnaces and various thermal equipments, and can endure various physical and chemical changes and mechanical effects at high temperature. For example, refractory clay brick, high alumina brick, cilica brick and magnesia brick and etc.. Fireclay -- usually refers to a kind of soil clay used for fire the stove and the furnace hearth in folk 1, characteristics and usages: Clay refractory brick is a kind of weak acid refractory material, its thermal stability is good, suitable for hot blast stove, various boiler lining, and flue, smoke room, etc.. 2, product specifications: Standard form, general profile, special shaped and special shaped brick. Physical and chemical properties of clay refractory bricks. The upper limit ---- about 1500 degrees under normal pressure

- Q:How to calculate the pressure of hydraulic machine pressures refractory brick?

- If it is a plunger type cylinder, the pressure of a cylinder is the cross-sectional area of the piston multiplied by the pressure of the hydraulic system; if it is piston cylinder, that is the inner diameter of the hydraulic cylinder multiplied by the pressure of the hydraulic system. Adopt cm as diameter's unit, a unit of pressure is kilogram force per square centimeter, the calculated result is kilogram which divided by one thousand is ton.

- Q:What's the reason of cracks in refractory bricks?

- This is inorganic nonmetallic material

- Q:What is the life of an old fashioned refractory brick kiln transformed into a flat topped tunnel kiln? what material should be used to transform the old fashioned refractory bricks vault kiln to flat tunnel kiln, and how long is the service life?

- High alumina brick and hanging brick are ok.

- Q:Can refractory bricks be used to pave roads or build a wall?

- Refractory bricks are used to build a house, no problem

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CN 40 Brick Fired Furnace Brick Lining Refractory Fireclay Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords