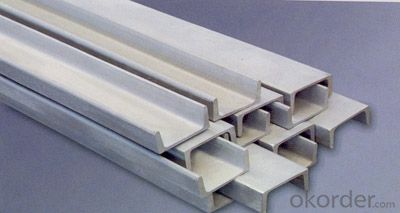

Channel Steel Galvanized for House, Wall, Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

C Channel steel bar

Material: Q195Q235Q345

Size: 10-300*0.5-6.0mm

Finished: Black, Galvanized

C Channel Steel Bar

| Tianjin Jujin Industry and Trading Co.,Ltd | |||||

| Dafengdui Village,Dafengdui Town,Jinghai Country,Tianjin City,China | |||||

| Tel:+86-22-68661881 Fax:+86-22-68663603 | |||||

| Country of Origin:China | |||||

| Tolerance:Accroding to clients'requirements | |||||

| Delivery time:7-25 days | |||||

| Payment term:L/C or T/T | |||||

| Packing:Mills Standard Export Strong Packing in Bundles | |||||

| Details Products Description | |||||

| C channel steel | |||||

| Material | Specificationmm | Thicknessmm | Weightkg/m | ||

| h | b | a | |||

| Q195-Q235 Q345 | 80 | 50 | 20 | 2.25 | 3.886 |

| 80 | 50 | 20 | 2.5 | 4.318 | |

| 80 | 50 | 20 | 2.75 | 4.749 | |

| 80 | 50 | 20 | 3 | 5.181 | |

| 100 | 50 | 20 | 2.25 | 4.239 | |

| 100 | 50 | 20 | 2.5 | 4.71 | |

| 100 | 50 | 20 | 2.75 | 5.181 | |

| 100 | 50 | 20 | 3 | 5.652 | |

| 120 | 50 | 20 | 2.25 | 4.592 | |

| 120 | 50 | 20 | 2.5 | 5.103 | |

| 120 | 50 | 20 | 2.75 | 5.613 | |

| 120 | 50 | 20 | 3 | 6.123 | |

| 140 | 60 | 20 | 2.5 | 5.888 | |

| 140 | 50 | 20 | 2.5 | 5.495 | |

| 140 | 60 | 20 | 3 | 7.065 | |

| 140 | 50 | 20 | 3 | 6.594 | |

| 160 | 50 | 20 | 2.5 | 5.888 | |

| 160 | 60 | 20 | 2.5 | 6.28 | |

| 160 | 70 | 20 | 2.5 | 6.673 | |

| 160 | 50 | 20 | 3 | 7.065 | |

| 160 | 60 | 20 | 3 | 7.458 | |

| 160 | 70 | 20 | 3 | 7.536 | |

| 180 | 50 | 20 | 2.5 | 6.28 | |

| 180 | 60 | 20 | 2.5 | 6.673 | |

| 180 | 70 | 20 | 2.5 | 7.065 | |

| 180 | 80 | 20 | 2.5 | 7.458 | |

| 180 | 50 | 20 | 3 | 7.536 | |

| 180 | 60 | 20 | 3 | 8.007 | |

| 180 | 70 | 20 | 3 | 8.478 | |

| 180 | 80 | 20 | 3 | 8.949 | |

| 200 | 50 | 20 | 2.5 | 6.673 | |

| 200 | 60 | 20 | 2.5 | 7.065 | |

| 200 | 70 | 20 | 2.5 | 7.458 | |

| 200 | 80 | 20 | 2.5 | 7.85 | |

| 200 | 50 | 20 | 3 | 8.007 | |

| 200 | 60 | 20 | 3 | 8.478 | |

| 200 | 70 | 20 | 3 | 8.949 | |

| 200 | 80 | 20 | 3 | 9.42 | |

| 220 | 50 | 20 | 2.5 | 7.065 | |

| 220 | 60 | 20 | 2.5 | 7.458 | |

| 220 | 70 | 20 | 2.5 | 7.85 | |

| 220 | 80 | 20 | 2.5 | 8.243 | |

| 220 | 50 | 20 | 3 | 8.478 | |

| 220 | 60 | 20 | 3 | 8.949 | |

| 220 | 70 | 20 | 3 | 9.42 | |

| 220 | 80 | 20 | 3 | 9.891 | |

| 240 | 50 | 20 | 2.5 | 7.458 | |

| 240 | 60 | 20 | 2.5 | 7.85 | |

| 240 | 70 | 20 | 2.5 | 8.243 | |

| 240 | 80 | 20 | 2.5 | 8.635 | |

| 240 | 50 | 20 | 3 | 8.949 | |

| 240 | 60 | 20 | 3 | 9.42 | |

| 240 | 70 | 20 | 3 | 9.891 | |

| 240 | 80 | 20 | 3 | 10.362 | |

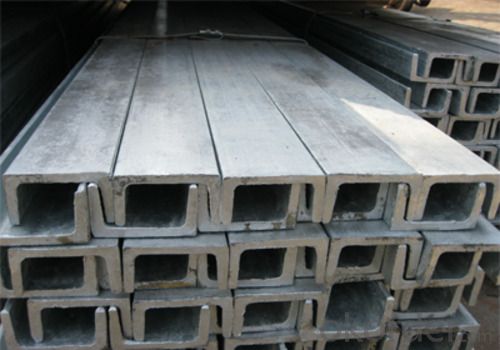

Channel bar

1.Competitive:manufacturer with ISO

2.competitive quality& price

3.Skype: judy.wf

Product Description

Products | Channel bar |

Grade | Q235,SS400B,A36,S235JR.ect |

Type | GB standard(10#-40#,100*48mm--400*102mm) JIS standard(50*25mm--250*90mm) |

Length | 6m, 12m |

Technique | Hot rolled |

Application | Mainly used for building structure, vehicle manufacturing and other industrial structure, channel steel is often used with i beam. |

Payment | 100% irrevocable L/C at sight 30% T/T prepaid and the balance against the copy of B/L |

- Q:How do steel channels contribute to the overall efficiency of a building?

- Steel channels contribute to the overall efficiency of a building in several ways. Firstly, they provide structural support, enhancing the strength and stability of the building. This allows for the construction of taller and larger structures, maximizing the use of space. Additionally, steel channels can be used to create open floor plans, allowing for flexible and versatile layouts. Moreover, steel channels are lightweight yet durable, making them easy to transport and install, reducing construction time and costs. Lastly, steel channels have high resistance to fire, corrosion, and pests, ensuring the long-term durability and safety of the building.

- Q:What are the factors that affect the cost of steel channels?

- The cost of steel channels can be affected by several factors. Firstly, the cost of raw materials plays a significant role. Factors like supply and demand, production costs, and global economic conditions can directly impact the price of steel, thus affecting the cost of steel channels. Another factor that influences the cost is the size and specifications of the channels. Larger or more specialized channels may require additional processing or customization, leading to increased costs. The complexity of the design or the need for specific coatings or finishes can also impact the final price. The manufacturing process itself contributes to determining the cost. Different production methods, such as hot-rolling or cold-forming, have varying associated costs. Additionally, the location of the steel production facility and transportation costs can affect the overall price. Market conditions and competition also have a role in determining the cost of steel channels. When demand is high and supply is limited, prices tend to rise. Conversely, during periods of low demand or increased competition, prices may decrease. Lastly, any additional services or value-added features, like cutting, drilling, or welding, can increase the cost of steel channels. These services require additional labor, equipment, and expertise, resulting in an overall higher price. In conclusion, the cost of steel channels is influenced by various factors, including raw material prices, size and specifications, manufacturing process, market conditions, competition, and additional services. It is crucial for businesses and consumers to understand these factors in order to make informed decisions when purchasing steel channels.

- Q:Are steel channels suitable for use in the construction of elevated storage systems?

- Yes, steel channels are suitable for use in the construction of elevated storage systems. Steel channels provide strength, durability, and stability, making them ideal for supporting heavy loads and withstanding the forces associated with elevated structures. Additionally, steel channels can be easily customized and are readily available, making them a practical choice for constructing elevated storage systems.

- Q:Can steel channels be used for staircase handrails?

- Yes, steel channels can be used for staircase handrails. Steel channels provide strength and durability, making them a suitable choice for supporting and guiding people along staircases.

- Q:What are the different types of corrosion protection for steel channels?

- Steel channels have various corrosion protection methods available, depending on specific requirements and environmental conditions. Some common methods include: 1. Galvanization: A highly popular corrosion protection method for steel channels involves coating them with a layer of sacrificial zinc. This prevents corrosion by corroding the zinc layer instead of the steel. 2. Powder coating: Channels can be protected by applying a dry powder, which is then baked to create a protective layer. This not only offers excellent corrosion resistance but also enhances the channels' aesthetics. 3. Epoxy coatings: Aggressive environments often require the use of epoxy coatings. These create a durable barrier against moisture and chemicals, preventing corrosion of the steel channels. 4. Paint coatings: Cost-effective paint coatings involve applying multiple layers to form a barrier between the metal and corrosive elements in the environment. 5. Hot-dip galvanizing: Immersing steel channels in molten zinc provides a thicker and more durable layer of protection compared to regular galvanization. 6. Cathodic protection: This technique protects steel channels by making them the cathode in a corrosion cell. Channels are connected to a sacrificial anode, such as zinc or magnesium, which corrodes instead of the steel. 7. Stainless steel: Using stainless steel channels is an effective way to prevent corrosion. The high chromium content forms a passive oxide layer on the surface, protecting it from corrosion. To ensure the longevity and durability of steel channels, it is essential to select the appropriate corrosion protection method based on factors such as the environment, expected lifespan, and cost considerations.

- Q:How do steel channels contribute to the overall safety of a structure during earthquakes?

- Steel channels contribute to the overall safety of a structure during earthquakes by providing additional structural support and resistance to lateral forces. They help distribute the seismic energy more evenly throughout the structure, preventing localized damage and potential collapse. The channels act as bracing elements, increasing the stiffness and rigidity of the building, which reduces the chances of structural failure during seismic events.

- Q:I have three houses, the length is 7 meters, the width is 4 meters, I would like to use a 4 meter trough board to do the support, and then put concrete slabs on the channel, the two floor of the roof also do so, can I do that? If it is possible to use a large trough plate, a thick concrete slab, and a thick steel bar for concrete slabs Thank you

- Channel steel, of course, when the beam, the best 3600*3600mm, plate thickness of 100mm, reinforced two-way double 8@200, grade three steel

- Q:What are the safety considerations when working with steel channels?

- When working with steel channels, it is necessary to consider several safety factors. To begin with, it is crucial to wear the appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots. This will help safeguard against potential hazards like sharp edges, flying debris, and falling objects. Furthermore, it is vital to inspect the steel channels for any defects or damage before commencing work. This involves checking for cracks, bends, or corrosion that could jeopardize the structural integrity of the channels. If any issues are detected, they should be rectified or the channels should be replaced to maintain a safe working environment. Proper lifting techniques and equipment should be employed when handling steel channels to prevent strain or injury. Since steel channels can be heavy and cumbersome to maneuver, using lifting aids like cranes, hoists, or forklifts can significantly reduce the risk of accidents or musculoskeletal injuries. Another safety consideration is ensuring the proper storage and stacking of steel channels. They should be stored in a designated area that is free from obstructions and away from other materials that may pose a risk of falling or causing damage. Stacking should be done securely and stably, with heavier or larger channels placed at the bottom to prevent toppling. When cutting or welding steel channels, it is important to adhere to proper safety procedures. This includes using the appropriate tools and equipment, ensuring adequate ventilation in enclosed spaces to prevent the accumulation of toxic fumes or gases, and wearing respiratory protection if necessary. Fire prevention measures, such as keeping fire extinguishers nearby and keeping flammable materials away from the work area, should also be implemented. Lastly, clear communication and coordination among workers are essential when working with steel channels. This can help prevent accidents, ensure awareness of potential hazards or risks, and facilitate prompt response in case of emergencies. By following these safety considerations when working with steel channels, the risk of accidents, injuries, and property damage can be minimized, creating a safer work environment for everyone involved.

- Q:Do steel channels have any specific load distribution characteristics?

- Yes, steel channels do have specific load distribution characteristics. Steel channels are commonly used in structural applications as they provide excellent strength and load-carrying capacity. The load distribution characteristics of steel channels depend on their shape, size, and orientation. Steel channels typically have a C-shaped cross-section, with a flat back and two perpendicular flanges. The load distribution characteristics of steel channels are primarily influenced by the flanges. The flanges act as beams that resist bending and carry the applied load. The load is distributed along the length of the flanges, creating a load path that transfers the load to the supports or other structural elements. The load distribution characteristics of steel channels are also influenced by the size and orientation of the channel. Larger channels with wider flanges can distribute the load over a larger area, reducing the stress concentration. Additionally, the orientation of the channel, whether it is vertical or horizontal, can affect the load distribution characteristics. It is important to consider the load distribution characteristics of steel channels during the design and analysis of structures. Engineers need to ensure that the channels are properly sized and oriented to adequately distribute the applied loads. By considering these characteristics, steel channels can effectively distribute the load and contribute to the overall structural integrity and stability of a construction project.

- Q:Which way is it better to weld the iron channel and galvanized steel channel in the house?

- Can be, do not want to paint on the steel galvanized, of course, Ironweed endurance

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Channel Steel Galvanized for House, Wall, Ceiling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords