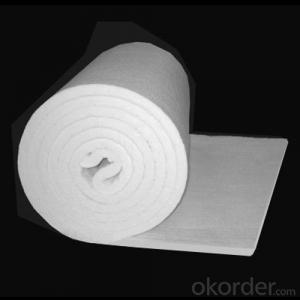

Ceramic Fiber Blanket Applied in Kiln Hot Face Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Composite of Ceramic Fiber Blanket Applied in Kiln Hot Face Lining

Ceramic Fiber Blanket is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Types of Ceramic Fiber Blanket: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Blanket also has difference, and they are suitable for different working temperatures.

Main Features of Ceramic Fiber Blanket Applied in Kiln Hot Face Lining

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Blanket Applied in Kiln Hot Face Lining

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

Ceramic Fiber Blanket Applied in Kiln Hot Face Lining

◆Product Process

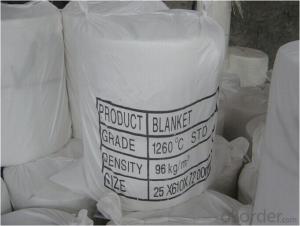

Ceramic Fiber Blanket Applied in Kiln Hot Face Lining Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 64,96, | 64,96, | 64,96, | 64,96, | |

128,160 | 128,160 | 128,160 | 128,160 | ||

Shrinkage on heating (%) | -3 | -3 | -3.5 | 3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Blanket Applied in Kiln Hot Face Lining

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q7:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q8:What is the service life of your products?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

Q9:Can you accept OEM for Ceramic Fiber Insulation Roll?

A:YES! We can according your demand to produce.

Q10:Can U accept the detective of the third-party verification company ?

A:YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q:BDU fabric options basically and I don't really know the difference between the options.

- In the US, the average electricity consumption for a house is 958 kwh per month which is 32 kwh per day for a 30 day month Once you get to New York City, the number of hours of usable sunlight drops to four hours per day so using six hours a day as a guideline and the fact that inverters tend to be 65% efficient, you wind up requiring 8.205 kw of solar panels which at $5 a watt amounts to $41,205 not including the inverterYour first task would be to reduce your energy useKeep in mind that the effective cost of solar power in 2007 was 38 cents per kwh Without government incentives, you wind up paying more for your electricity than had you just bought it from the grid.

- Q:During midsummer, the couples were slept with their 4 yrs old childrenThe temperature was warm and humid, used bed sheet as their blanketAfter couple of an hour, the father and mother was on climax, the cool air blew when father bumsThe child was felt relax when the cool air blownAfter even the child asked, father can u bums some more? Father said 'huh’ now no more energy!!!

- cool down with 20 minutes of white water rafting in the nearby tongariro river

- Q:This is my third day on the two week special k diet and since day 1 I've been constipatedMy b.m.'s are hard and it freakin hurts! Will this go away or should I stop the diet asap? I drink 8 cups of water daily and eat fruit with my cereal so whats the problem?

- I like Bare Minerals, but over time I have started to prefer Ecco Bella and Burt's BeesIn terms of coverage (blemishes, etc), Bare Minerals is a little better than Ecco Bella, but if your skin is breaking out, it can be indicative of a poor diet or stressI don't have to wear much foundation because I take an herbal combination called Skin Detox from a company called Nature's SunshineSince I don't eat a lot of junk food in the first place, the herbal combo helps give my skin that extra boost to stay clear, which results in me having better coverage results with Ecco Bella and Burt's Bees.

- Q:Ceramic fiber blanket afraid of water?

- The conventional ceramic fiber blanket is afraid of the water, because the ceramic fiber blanket has very strong water absorption, water absorption ratio of 1:10, when the ceramic fiber blanket after the water will become a conductor, the heat transfer effect and water, ceramic fiber blanket thermal insulation function lose all.

- Q:I have blown in insulation in my Attic and a new roof with a ridge ventThe roofers said to make sure the eaves are not blockedWhen I go up into the attic and dig out insulation from the eaves it never endsI can put my whole arm up to my shoulder in that quot;areaquot; I do not see daylight, like everyone tells meFrom the outside of my house it looks like the eaves go down below the attic areaLike the eave would be in the bedrooms belowHow do I access my eaves to clean them out? From the soffit outside?

- NoThe only way to block calories is to not put it in your mouthOr to not digest it.

- Q:I need a description of its parts, how they are connected and how it functions

- The white coating could be Thrush, its a yeast infectionSee a doctorToo much fiber causes bloating and constipation.

- Q:I am a male teenager who runs cross-country in high school, I have little-to-no body fat, and at night, I get very cold and sleep under a sheet, a light blanket, two heavy blankets, and a feather comforterI have heard from my parents that it is just because I am slim, but I am not so sureWe do not keep the air conditioner on at night, and it maintains a temperature somewhere around 77 or 78 degreesI was just wondering if my parents were right or if it was something else.

- Athletes tend to have slightly higher body temperatures so everything feels cold to youMy friend who plays soccer has the same problem she is always wearing a hoodie and jeans and we live in southern california(She asked her doctor about it) You're completely fine :]

- Q:She seems to get bloated a lot and she doesn't have a bowel movement everydayAnd when she does, they smell abnormally bad and I'm afraid her digestive tract may be backed upI want to put her on a high fiber diet to get it movingAny suggestions on some high fiber foods I can regularly implement or any child friendly 'digestive tract cleansing' supplements?Thanks!PSPlease only give suggestions other than bring her to the doctorShe is already going todayBut I wanted to hear some first hand knowledge/suggestions from other moms and dads as well.Thanks!

- Snuck out of the house: Yes Lied to get out of trouble: Yes Had a computer crash: Yes Gotten lost in your city: Yes Seen a shooting star: Yes Been to any other countries: Yes Had a serious surgery: No Stolen something important to someone else: Yes Solved a rubiks cube: No Gone out in public in your pyjamas: Yes Kissed a random stranger: No Hugged a random stranger: Yes Been in a fist fight: Yes Been arrested: No Done drugs: No Had alcohol: Yes Laughed and had milk come out of your nose: Yes (but it was soda) Pushed all the buttons on an elevator: Yes Sneaked into the opposite sex's bathroom: Yes! Gone to school only to find you had the day off because of a holiday/etc: Yes, what a terrible daySwore at your parents: NoKicked a guy where it hurts: YesRan over an animal and killed it: YESHad a water balloon fight in winter: Yes.

- Q:I dont eat fruitsBut I can drink some of the fruit juices like mango, orange, apple.Im starting to feel the effectsEspecially my skin and digestionsI tried several times eating fruits.But.umm.i just cantThe taste was like.ou man.Its like an intruder for my taste budDamnPleaseI need fruits! But I cant eat them even if I try to.Is this normal for some people?? Does fruit juice good enough for our health? Do they hav the same nutritions?

- hair grows 1/2 inch to an inch a month so you figure that part out sadly no there is no shampoos that can make hair grow try to eat healthy and take vitamins and also take really good care of your hair and body

- Q:i eat hazelnuts alot and today i just checked the facts on them and this is what i found out Hazelnut High in dietary fiber, potassium, calcium, magnesium and vitamin E, hazelnuts are nutritious as well as tasty28 grams of chopped hazelnuts contains: 178 Calories, 4 grams protein, 17 grams fat, 5 grams carbohydrate, 2.7 grams dietary fiberSo are hazlenuts fattening though they are high in fiber??????I eat alot of them prob like 3/4 cup a day .is that bad????? should i not include it in my eating habits plz give me all ur opinions

- use a vegetable bean dip such as hummus instead of ranch dressing or a fatty cream based dip

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Fiber Blanket Applied in Kiln Hot Face Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords