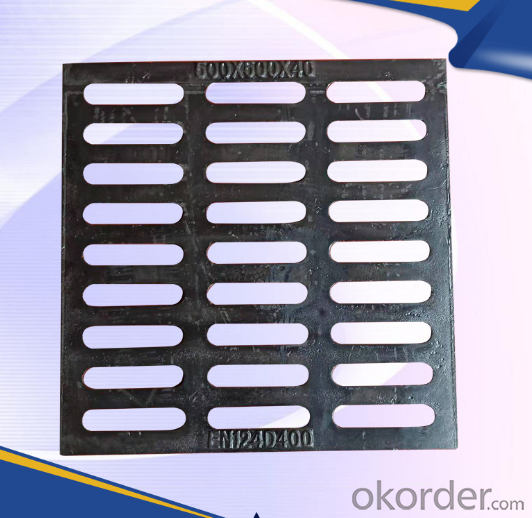

Cast ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) we can produce as per customers'drawings

4) Waterproof and anti-rust

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) |

| CCUC68HK | C250 | 500*700 | 600*800 | 60 |

| CCUC70HK | C250 | 600*600 | 700*700 | 50 |

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

Advantages

Good compressive, bending and impact strength, anti-rust, endurable period (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other companies.

Packaging & Shipping

Packaging: Details Pallet with bubble film,

Delivery Detail: 8 days if your order is 20"container

FAQ

1. How about your price?

A: As one of famous manufacturers of Ductile iron products inChina, Our prices are very favorable and competitive. The customers from all-over the world.

2. Can I get free samples?

A: Yes, we can provide the free samples, but you need to bear delivery freight.

3.How about your service?

A: Free charge of design labels and cartons.

Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

Professional technical support with free charge.

- Q:What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q:What are the requirements for casting steel castings?

- 2, the plane should be placed on the following.3, thin parts should be placed below.

- Q:What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

- Q:What are the casting parts processing engineering?

- At present, casting processing, according to metal classification, divided into cast iron, cast steel, casting non-ferrous metal.

- Q:Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q:Domestic large steel castings factory which is better, recommend!

- Do the casting manufacturer of large steel castings, Hunan Jinsha heavy industry science and technology limited company, heard that their professional only more than 1 tons of steel castings, anyway, 150T just big, the company won a lot of foundry industry patents should be good.

- Q:Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q:How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q:the parts of the threaded hole is casting, casting the hole directly, and then tapping or casting, and then punch 10When the casting is ready, punch it again before tapping it Is the hole casting good or is it punched and tapped on the drilling machine after casting?

- Aluminum alloy die-casting parts or casting box and other parts of the threaded hole, in the case of processing conditions, it is best to use wire tapping or machine tool processing! Direct casting is not advocated.

- Q:After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cast ductile iron manhole cover for mining made in Hebei Province

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products