Carbon Steel Square Straight Bars with Sizes 10MM to 25MM High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Carbon Steel Square Straight Bars with Sizes 10MM to 25MM Description:

Carbon steel square straight bars with sizes 10mm to 25mm is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, carbon steel square straight bars with sizes 10mm to 25mm is still in the form of a metal bar or rectangle. Small sizes of carbon steel square straight bars with sizes 10mm to 25mm are used in ship building.

2. Main Features of Carbon Steel Square Straight Bars with Sizes 10MM to 25MM:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

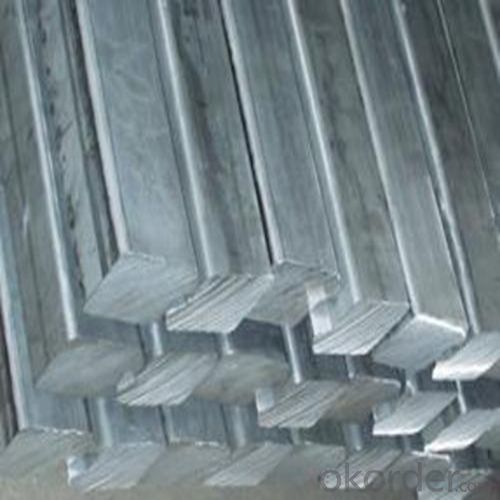

3. Carbon Steel Square Straight Bars with Sizes 10MM to 25MM Images:

4. Carbon Steel Square Straight Bars with Sizes 10MM to 25MM Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q:How do you use a steel square to find angles for coping cuts?

- To determine angles for coping cuts, there are several steps you should follow: 1. Begin by identifying the specific angle you need to cut, whether it is a corner angle or a miter joint angle. 2. Position the steel square on the workpiece, ensuring that one side of the square is aligned with the material's edge. 3. Rotate the square until the opposite side is aligned with the adjacent edge or surface. This will create a corner where the two material edges meet. 4. Once the square is aligned correctly, use a pencil or scribe to mark the angle on the workpiece by drawing along the square's edge. 5. Remove the square from the workpiece and extend the marked line as necessary. 6. Finally, execute the coping cut along the marked line using the appropriate tool, such as a coping saw or jigsaw. By utilizing a steel square to determine angles for coping cuts, you can accurately transfer the angle from one material piece to another, ensuring a precise fit for your project. It is crucial to verify your measurements and make any required adjustments prior to making the final cut.

- Q:How do you use a steel square to determine board footage?

- To use a steel square to determine board footage, you will need to follow a few simple steps. First, measure the width of the board using the shorter arm of the steel square. Place the square against the edge of the board and align the shorter arm with the width of the board. Take note of the measurement marked on the longer arm of the square where it intersects with the edge of the board. Next, measure the length of the board using the longer arm of the steel square. Place the square against one end of the board and align the longer arm with the length of the board. Again, take note of the measurement marked on the shorter arm of the square where it intersects with the end of the board. Multiply the width and length measurements together to calculate the square footage of the board. For example, if the width is 6 inches and the length is 8 feet, the calculation would be 6 inches multiplied by 8 feet, resulting in 48 square feet. To determine the board footage, which represents the volume of the board, divide the square footage by 12 (since there are 12 inches in a foot) and round to the nearest whole number. In the previous example, dividing 48 square feet by 12 would give a board footage of 4. Using a steel square to determine board footage is a straightforward process that can be easily accomplished with accurate measurements and basic multiplication and division calculations.

- Q:What are the common applications of a steel square in masonry work?

- A versatile tool commonly used in masonry work is the steel square, also known as a framing square or carpenter's square. It has various functions, such as measuring, marking, and cutting materials. When it comes to masonry work, one of the primary uses for a steel square is laying out and verifying right angles. Masons rely on the square to ensure that corners are perfectly square, which is crucial for achieving proper alignment and stability in masonry structures. By placing the square against the corner of a wall or foundation, they can determine if it forms a 90-degree angle. If adjustments are necessary, they can be made to ensure the accuracy of the construction. Another common application of the steel square in masonry work is precise measurements. The tool has markings along its blade and tongue, allowing masons to accurately measure various dimensions. They can use it to measure the length and width of bricks or blocks, ensuring that they meet the desired size and shape requirements. Moreover, marking lines on masonry materials is another important task for which a steel square is utilized. Before cutting or installing bricks, blocks, or other materials, masons often need to mark cut lines or reference lines. By aligning the square's straight edge with the desired line, they can accurately mark the material using a pencil or scribe. Additionally, a steel square serves as a cutting guide in masonry work. Masons occasionally need to make straight cuts on bricks or blocks to fit them into specific spaces. Using the square as a guide for a masonry saw or chisel ensures that the cuts are straight and precise. Overall, the steel square is an essential tool for masons due to its versatility and accuracy. It enables them to check right angles, make precise measurements, mark lines, and serve as a cutting guide. By utilizing the steel square, masons can achieve precise and high-quality masonry construction.

- Q:How do you use a steel square to determine the height of a tree?

- If you want to determine the height of a tree using a steel square, follow these steps: 1. Locate a suitable spot with a clear view of the entire tree from a distance. 2. Stand at a distance from the tree where you can hold the steel square vertically without obstacles. 3. Hold the steel square in your hand and make sure it is aligned vertically. Keep one edge parallel to the ground. 4. Fully extend your arm, holding the steel square against your thumb and forefinger. 5. Adjust your arm so that the bottom edge of the steel square lines up with the base of the tree trunk. 6. Peer through the small hole in the steel square at the top of the tree. You should be able to see the tree's top through the hole. 7. While maintaining a steady arm and steel square, move backward or forward until the top of the tree aligns with the bottom edge of the steel square. This indicates that the tree's height is equal to the distance between you and the tree. 8. Once you have determined the correct distance, measure it using a measuring tape or another reliable tool. 9. The measured distance represents the height of the tree. It's important to keep in mind that this method provides an approximate tree height, assuming a right-angle triangle with you, the tree, and the steel square. Factors like uneven ground, tree shape, and the height of your arm may introduce some margin of error. For a more precise measurement, it is advisable to use alternative methods such as the triangulation method or laser-based tools specifically designed for measuring tree height.

- Q:Can a steel square be used as a level?

- No, a steel square cannot be used as a level. While a steel square is a useful tool for measuring angles and checking the accuracy of right angles, it does not have the necessary features to determine whether a surface is level or not. A level typically consists of a long, straight body with a bubble vial filled with liquid and an air bubble. This bubble vial allows for precise measurement of both horizontal and vertical surfaces, ensuring that they are perfectly level. Therefore, if you need to determine if a surface is level, it is recommended to use a proper level tool rather than a steel square.

- Q:How do you use a steel square to determine the angle of a compound fluting cut?

- To use a steel square to determine the angle of a compound fluting cut, you will need to follow these steps: 1. Start by positioning the steel square on the workpiece in a way that its long side is parallel to the edge of the material you want to flute. 2. Align one of the edges of the steel square with the edge of the material. Make sure it is firmly held in place. 3. Next, draw a line along the other edge of the steel square onto the material. This line will serve as a reference for the angle of the fluting cut. 4. Measure the angle between the reference line and the desired direction of the fluting cut. You can use a protractor or a bevel gauge to get an accurate measurement. 5. Once you have determined the angle, transfer it to your cutting tool or machine. This could be a router, a table saw, or any other tool capable of making the fluting cut. 6. Set up your cutting tool or machine to match the measured angle. This may involve adjusting the table or fence on a table saw, or changing the angle of the router bit. 7. Double-check your setup to ensure that the tool or machine is aligned correctly before starting the cut. 8. Finally, make the compound fluting cut by carefully guiding the material through the cutting tool or machine, following the determined angle. Remember to always prioritize safety when working with cutting tools or machines. Wear appropriate protective gear and follow the manufacturer's instructions to prevent accidents and injury.

- Q:Can a steel square be used for checking the squareness of a jointer bed?

- No, a steel square cannot be used for checking the squareness of a jointer bed. A jointer bed requires a precision tool like a precision square or straight edge specifically designed for measuring and ensuring the squareness of surfaces.

- Q:How do you use a steel square to find the slope of a ramp?

- To use a steel square to find the slope of a ramp, you can follow these steps: 1. Place the steel square on the ramp, with one side resting on the surface of the ramp and the other side perpendicular to it. 2. Make sure the steel square is level and properly aligned with the ramp. 3. Using a level, check if the steel square is perfectly horizontal. Adjust the angle of the ramp if needed until the steel square is level. 4. Once the steel square is level, observe the side of the square that is perpendicular to the ramp. This side will indicate the slope of the ramp. 5. Determine the slope by measuring the vertical distance between the surface of the ramp and the bottom edge of the steel square, and the horizontal distance between the bottom edge of the steel square and the ramp. 6. Calculate the slope by dividing the vertical distance by the horizontal distance. This will give you the slope as a ratio or a percentage. For example, if the vertical distance is 2 inches and the horizontal distance is 10 inches, the slope would be 2/10 or 0.2, which can be expressed as 20% slope. Using a steel square allows you to accurately measure the slope of a ramp and ensure it meets the desired specifications or safety standards.

- Q:What are some common applications for a steel square in plumbing installations?

- A steel square, which is also referred to as a framing square or carpenter's square, possesses a wide range of applications within plumbing installations. Here are several typical uses for a steel square in plumbing: 1. Angle determination: To accurately measure and designate angles, a steel square can be employed. This proves particularly advantageous in plumbing installations that require pipes to be cut and connected at specific angles, such as water supply lines or drain systems. 2. Corner squaring: Plumbing systems frequently necessitate the connection of pipes at right angles. A steel square can be utilized to ensure that corners are perfectly squared, a crucial aspect for leak-free connections and proper water flow. 3. Level and plumb checking: Plumbers utilize a steel square to verify whether pipes or fixtures are level and plumb. This is significant in guaranteeing the effectiveness of drainage systems and the proper alignment of fixtures such as sinks or toilets. 4. Pipe run layout: Steel squares can be employed to lay out the course of pipes, particularly in intricate plumbing systems. By using the square to mark measurements and angles on the floor or walls, plumbers can accurately plan and install pipes in the desired configuration. 5. Measurement and marking: Steel squares possess markings along their edges that can be utilized to measure distances and make precise markings on materials. Plumbers can utilize these measurements to cut pipes to the correct length or align fixtures with precision. 6. Template creation: In certain plumbing installations, pipes with unique or irregular shapes must be cut. A steel square can be employed to create templates by tracing the required shape onto a piece of cardboard or plywood. This template can then serve as a guide during the cutting process. In summary, a steel square proves to be an invaluable tool for plumbers, ensuring accuracy, proper alignment, and efficient installation of plumbing systems. Its versatility and usefulness make it a staple in a plumber's toolkit.

- Q:How do you use a steel square to lay out a parallelogram?

- To use a steel square to lay out a parallelogram, you would start by marking a straight line using the long edge of the steel square. Then, you would use the shorter edge of the square to mark two perpendicular lines from the ends of the straight line. Finally, connect the ends of the perpendicular lines to complete the parallelogram shape.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Steel Square Straight Bars with Sizes 10MM to 25MM High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords