All Categories

- - Steel Wire Rod

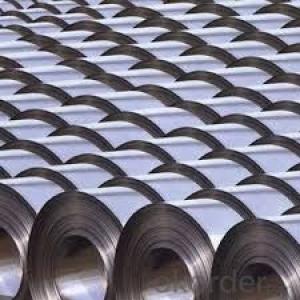

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

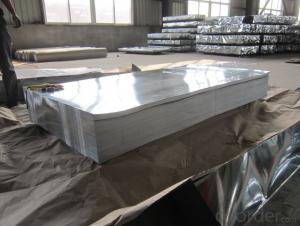

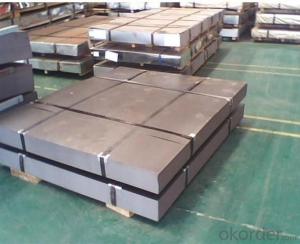

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

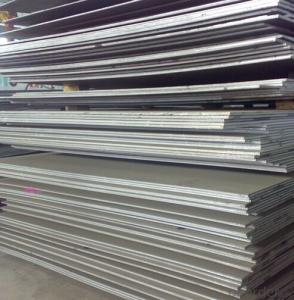

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the considerations when welding dissimilar metals to hot-rolled steel?

When welding dissimilar metals to hot-rolled steel, there are several important considerations. First, it is essential to understand the properties and characteristics of both the dissimilar metals and the hot-rolled steel, including their melting points, chemical compositions, and thermal expansion rates. This knowledge will help in determining the appropriate welding techniques and filler materials to use.

Additionally, it is crucial to ensure proper joint preparation and fit-up to achieve strong and durable welds. This may involve removing any surface contaminants, such as oils or rust, and creating precise joint designs that promote effective fusion between the dissimilar metals and hot-rolled steel.

Matching the welding process and parameters to the specific needs of the dissimilar metals and hot-rolled steel is also critical. Different metals may require specific welding techniques, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas), and adjusting factors like heat input, travel speed, and shielding gas composition to achieve optimal results.

Finally, post-weld heat treatment or other forms of stress relief may be necessary to minimize the risk of cracking or distortion in the welded joints. This step is especially important when dealing with dissimilar metals, as their different thermal expansion rates can create residual stresses that may affect the integrity of the welds.

Overall, considering the properties of the dissimilar metals and hot-rolled steel, joint preparation, suitable welding techniques, and post-weld treatments are key factors to ensure successful welding of dissimilar metals to hot-rolled steel.

Can hot-rolled steel be used for automotive applications?

Yes, hot-rolled steel can be used for automotive applications. It is commonly used in the manufacturing of various automotive components such as frames, chassis, and structural parts due to its excellent strength and durability properties.

How is hot rolled steel used in the construction of power plants?

Hot rolled steel is commonly used in the construction of power plants due to its strength, durability, and cost-effectiveness. It is utilized in various applications such as structural frames, beams, columns, and supports for power plant buildings and facilities. Additionally, hot rolled steel is used in the fabrication of heavy-duty equipment, such as turbines, generators, boilers, and pressure vessels, which are crucial components of power plants. Its ability to withstand high temperatures and pressure makes it an ideal material choice for these demanding environments.

What are the applications of hot rolled steel in the manufacturing of machinery?

Hot rolled steel has various applications in the manufacturing of machinery. It is commonly used to create parts and components that require high strength and durability, such as gears, shafts, frames, and structural supports. The process of hot rolling enhances the material's mechanical properties, making it suitable for heavy-duty applications in machinery manufacturing. Additionally, hot rolled steel can be easily formed and welded, allowing for flexibility in design and assembly. Overall, hot rolled steel contributes to the production of robust and reliable machinery.

Wholesale Hot Rolled Steel from supplier in Finland

Our team of experts understands the unique needs and requirements of the Finnish market when it comes to Hot Rolled Steel. We have established strong relationships with reliable suppliers to ensure that we can offer a wide range of high-quality products at competitive prices.

Whether you need Hot Rolled Steel for construction, manufacturing, or any other industry, we have you covered. Our extensive product portfolio includes various grades and sizes of Hot Rolled Steel, allowing us to meet the specific demands of your projects.

In addition to our comprehensive product range, we also offer a range of services to support your procurement process. Our team can assist you with product selection, technical specifications, and logistics, ensuring a smooth and efficient supply chain.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the financial stability and resources to ensure reliable and timely delivery of Hot Rolled Steel to Finland. Our commitment to customer satisfaction is at the core of everything we do, and we strive to exceed your expectations with our products and services.

Whether you are a small business or a large corporation, we are here to help you succeed. Contact us today to discuss your Hot Rolled Steel needs in Finland and experience the difference we can make for your business.

Whether you need Hot Rolled Steel for construction, manufacturing, or any other industry, we have you covered. Our extensive product portfolio includes various grades and sizes of Hot Rolled Steel, allowing us to meet the specific demands of your projects.

In addition to our comprehensive product range, we also offer a range of services to support your procurement process. Our team can assist you with product selection, technical specifications, and logistics, ensuring a smooth and efficient supply chain.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the financial stability and resources to ensure reliable and timely delivery of Hot Rolled Steel to Finland. Our commitment to customer satisfaction is at the core of everything we do, and we strive to exceed your expectations with our products and services.

Whether you are a small business or a large corporation, we are here to help you succeed. Contact us today to discuss your Hot Rolled Steel needs in Finland and experience the difference we can make for your business.