All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel sheets used in the development of earthquake-resistant building structures?

Steel sheets are commonly used in the development of earthquake-resistant building structures as they provide strength, flexibility, and durability. These sheets can be used as reinforcing elements in concrete walls, floors, and columns to enhance their resistance to seismic forces. Steel sheets can also be used to create moment-resisting frames and brace systems, which help to dissipate and absorb seismic energy, reducing the impact of earthquakes on the structure. Additionally, steel sheets can be utilized in the construction of base isolators or dampers, which further improve the building's ability to withstand seismic movements.

What is the role of steel sheets in the development of energy-efficient and sustainable data centers?

Steel sheets play a crucial role in the development of energy-efficient and sustainable data centers as they are used in the construction of the server racks and cabinets. These steel structures provide the foundation for housing and organizing servers, networking equipment, and storage devices. By utilizing steel sheets, data centers can optimize their space, improve airflow, and enhance cooling efficiency, ultimately reducing energy consumption. Additionally, steel's durability and recyclability contribute to the sustainability of data centers, as it allows for the reuse and repurposing of materials, minimizing waste in the construction and operation of these facilities.

How are steel sheets incorporated into the manufacturing of advanced robotics and automation systems?

Steel sheets are often used in the manufacturing of advanced robotics and automation systems to create strong and durable components such as frames, brackets, and housing. These steel sheets provide structural integrity and stability to the robotic systems, allowing them to withstand heavy loads and perform precise movements. Additionally, steel sheets can be easily machined, welded, and formed into complex shapes, making them versatile for various robotic applications.

What is the difference between hot-rolled and cold-rolled steel sheets?

The main difference between hot-rolled and cold-rolled steel sheets lies in the manufacturing process. Hot-rolled steel sheets are produced at high temperatures, which results in a rougher surface and less precise dimensions. On the other hand, cold-rolled steel sheets are processed at lower temperatures, resulting in a smoother surface finish and more accurate dimensions. Additionally, hot-rolled steel sheets tend to be more ductile and have a higher yield strength, while cold-rolled steel sheets are typically stronger and have better surface quality.

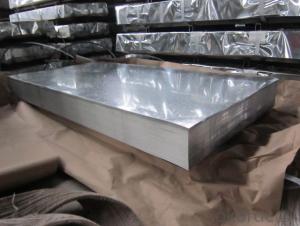

Wholesale Steel Sheets from supplier in Maldives

We are a Steel Sheets supplier serving the Maldives, mainly engaged in the sale, quotation, and technical support services of various Steel Sheets products in the Maldives region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Sheets procurement services in the Maldives. Not only do we have a wide range of Steel Sheets products, but after years of market development in the Maldives, we can also provide valuable experience for your projects.