Calcium Silicate Insulation Block Sheet Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Calcium Silicate Boards) Description

1.Obtained CE, KR and ISO9001;

2.Heat resistance temperature is up to 1100 degree centigrade;

3.Low price and best quality.

Description of our products

Calcium Silicate Board is a kind of high efficiency energy-saving and Environmentally friendly materials with temperature limited 1150 cent-degree. They are recommended as thermal insulations of equipment in power station, steel mill and petrochemical industries as well as other various fields. It can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, are also applicable to places where high security is needed.

Advantages of our products

1. we have own factory to produce the boards, and we are not the trading company, so we would have the directly customer service and the warranty of our boards is very good;

2. We obtained CE, KR and ISO9001;

3. The highest heat resistance temperature is up to 1100 degree centigrade;

4.The maximum flexural strength is up to 0.7MPa, all technical parameters are the best in China, it is better than other calcium silicate board in the market.

5.Our factory is corporate with the big power plant, uses the steam of the power plant to product the board, it is different from other factories to produce with the boiler. The product use the steam, the quality is better than use the boiler, so the technical parameters of our product are the best in factory. And it is very easy to mass product and reduce the waste, the cost is lower than our factory use boiler. So that the product from our factory is best quality and cheapest price.

2,Main Features of the (Calcium Silicate Boards)

Types of products

1. Standard type Calcium Silicate Board

2. JN High-temp Type Calcium Silicate Board

3. High density Calcium Silicate Insulation material Board

4. High strength calcium silicate boards

5. Core Board of Fire Door

6.External wall calcium silicate board

7.Thermal insulation pipe cover

8. Light weight low thermal conductivity calcium silicate board 130kg/m³

Product advantage :

Excellent chemical stability

Low thermal conductivity;

Low heat capacity;

Excellent sound absorption and noise reduction performance

Physical performance data:

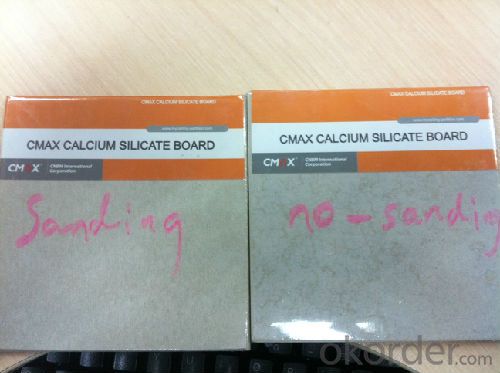

3,(Calcium Silicate Boards) Images

4,(Calcium Silicate Boards) Specification

Physical tech datas | 170 | 220 | 240 |

Density(kg/m3) | 170 | 220 | 240 |

Quality moisture content(%) | ≤7.5 | ≤7.5 | ≤7.5 |

Compressive strength(Mpa) | ≥0.40 | ≥0.50 | ≥0.50 |

Flexural strength(Mpa) | ≥0.20 | ≥0.30 | ≥0.30 |

Termal conductivity(W/m.k) | 0.058 | 0.062 | 0.062 |

Work temperature | 650 | 650 | 650 |

Linear shrinkage(%) | ≤2 | ≤2 | ≤2 |

Size | 600*300*25-100mm, 500*500*25-100mm | ||

Length(±3 mm) mm | Width(±3 mm) mm | thickness(+2 mm-1.5mm) |

1260 | 1260 | 50--120 |

1000 | 500 | 50--120 |

600 | 400 | 40--120 |

600 | 300,150 | 30--140 |

500 | 500 | 50--120 |

400 | 250 | 25--140 |

Products with max. service temp. of 1050°C are also available here.

5,FAQ of (Calcium Silicate Boards)

Application:

Petrochemical industry

Iron & steel industry

Cement industry

Glass industry

Shipping industry

- Q:What is the difference between the board and the silicon board?

- Calcium silicate board contains asbestos ingredients, asbestos is a high carcinogen, harmful to humans. Ette board is fibrous silicate board, does not contain asbestos, is environmentally friendly material non-toxic harmless

- Q:Calcium silicate board above the watermark is how to cause

- Yellow whirring, and generally the reasons for the use of kraft paper fiber, dry after generally not anti-color, but I suggest you use sanded calcium silicate board, such problems will be less.

- Q:Will the calcium silicate board shrink when it is finished or finished?

- Thermal expansion and contraction is a common property of all substances, but the thermal expansion and contraction coefficient of the size of the difference. Calcium silicate board in the decoration has not yet universal, the national standard can not be developed, are based on corporate standards as a product acceptance criteria.

- Q:What is the size and classification of calcium silicate board? How do we choose the specifications for their own calcium silicate board?

- There are kilns with the use of the wall with the cut, the furnace insulation with a low temperature [650 degrees], high temperature [1050 degrees] two, the specifications are generally 600 * 300 * 25-100mm, rain off Thermal energy-saving materials Co., Ltd. mainly produces these two kinds of microporous calcium silicate board

- Q:Silicon calcium board and mineral wool board difference between the price is the price, and the advantages and disadvantages of the material

- Silicon calcium board and mineral wool board main differences in sound and weight, silicon calcium board sound-absorbing performance is poor, similar to gypsum board.

- Q:Silicon calcium board can be used for external walls

- Calcium silicate board is less to do outside the wall panels, are generally decorated with interior walls

- Q:What is the difference between perforated calcium silicate wallboard and gypsum board?

- Silicon calcium board was first used in high temperature furnace insulation. Such as "in order to improve the quality of shaft kiln clinker material, easy to coal blending and reduce clinker burning coal consumption, we must strengthen the kiln kiln body insulation.Often the practice is to use the internal insulation method, refractory layer, the total thickness of the insulation layer should be ≥ 650mm, near the kiln wall should be added ≥ 60mm calcium silicate board or aluminum silicate fiber mat ".

- Q:Who can tell me silicon calcium board, calcium silicate board, high crystal board, paperless gypsum board, glass fiberboard in the end what is the difference

- Silicon calcium board and calcium silicate board are also two different materials. Silicon calcium board is mainly composed of gypsum, and calcium silicate is composed of quartz, mica, wood fiber and other components. Followed by the use: calcium calcium board is mainly used for indoor ceiling, and it also high-grade, mid-range, low-grade distinction, the best is solid silicon calcium board, moisture, fire, pollution, low carbon, clean surface, durability it is good. The calcium silicate board can be used for indoor and outdoor partitions, ceiling, surface decoration, firewall, fire ceiling, steel fire, high temperature insulation and many other environments, calcium silicate board also has good or bad points, Harmless to the human body, poor raw materials sucks, containing asbestos, carcinogenic. So choose a good silicon calcium board is very important, only work rigorous, good reputation, but also extremely responsible for the manufacturers will be in accordance with the standard production of non-toxic refractory quality excellent plate.

- Q:Gypsum board, Etter board, calcium silicate board, mineral wool board physical properties of what is different, the kind of hotel for the ceiling is more appropriate?

- Ette board for the tile wall, calcium silicate board is better, but the cost is certainly better than the gypsum board, in order to economic effect, the effect is good, with gypsum board

- Q:Calcium silicate board and magnesium silicate board which is better

- In recent years, with the improvement of production technology, the use of calcium silicate board is also more and more common in Guangdong, in addition to the external brand of Etterit, there are Oulang, Jinfu, Chun Figure, Yin Xing and other own Brand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Insulation Block Sheet Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords