Brushed Aluminum Sheet for Sale in All Kinds Alloy Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Brushed Aluminum Sheet for Sale in All Kinds Alloy Series

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Brushed Aluminum Sheet for Sale in All Kinds Alloy Series

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

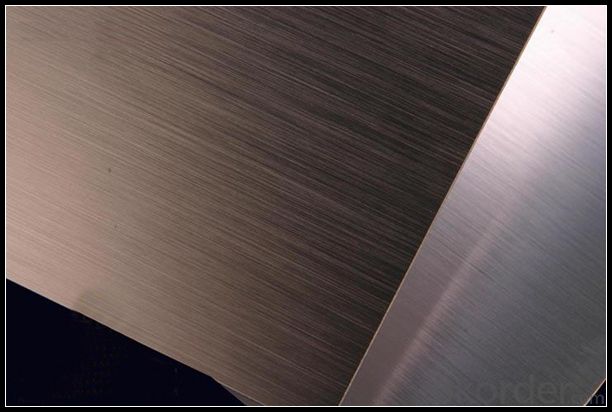

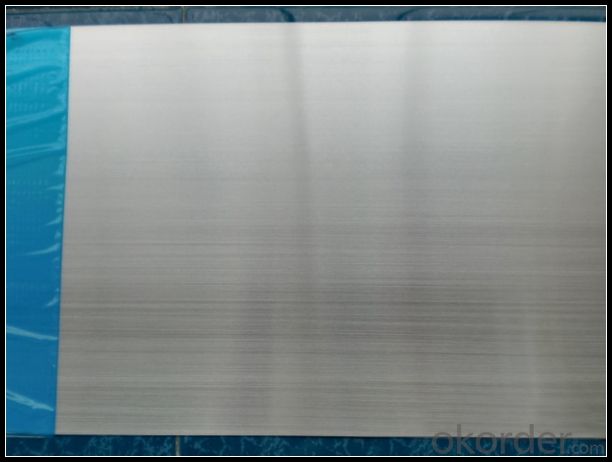

3. Brushed Aluminum Sheet for Sale in All Kinds Alloy Series Images

4.Specification of Brushed Aluminum Sheet for Sale in All Kinds Alloy Series

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Are aluminum sheets suitable for architectural louvers?

- Indeed, aluminum sheets prove to be a fitting option for architectural louvers. The advantageous properties of aluminum make it a favored material for louvers in the field of architecture. To begin with, aluminum possesses the desirable combination of being lightweight and yet sturdy, which makes it an ideal material for architectural louvers. It has the ability to withstand external forces such as wind and various weather conditions while maintaining its structural integrity. This becomes crucial for louvers as they are required to provide ventilation and airflow, all the while retaining their form and functionality. Furthermore, aluminum displays a high level of resistance against corrosion and rust. Considering that louvers are frequently exposed to outdoor elements like rain, moisture, and sunlight, the corrosion resistance of aluminum ensures the longevity and durability of the louvers, even in harsh environmental conditions. In addition, aluminum is an adaptable material that can be easily customized and fabricated into different shapes and sizes. This flexibility allows architects and designers to fashion louvers with unique designs and configurations that suit the specific requirements of the building. Aluminum louvers can be personalized to optimize airflow, control light, and enhance aesthetic appeal. Moreover, aluminum stands out as a sustainable and environmentally friendly material. It is widely recyclable, which means that aluminum louvers can be easily repurposed or reused at the end of their life cycle. Opting for aluminum in the construction of architectural louvers aligns with sustainable building practices and contributes to the overall reduction of environmental impact. In conclusion, aluminum sheets are indeed a suitable choice for architectural louvers. Their lightweight yet robust nature, resistance to corrosion, ability to be customized, and sustainability make them an excellent option in terms of functionality, durability, and aesthetics.

- Q:Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that offers several advantages for sculpting purposes. Firstly, it is lightweight, making it easier to handle and manipulate. This allows artists to create intricate and detailed sculptures without compromising on structural integrity. Additionally, aluminum is highly malleable, meaning it can be shaped into various forms and contours. This allows artists to experiment with different designs and achieve the desired artistic expression. Furthermore, aluminum is resistant to corrosion and weathering, making it ideal for outdoor sculptures. Its durability ensures that the artwork will withstand the elements and retain its aesthetic appeal over time. Additionally, aluminum sheets can be easily welded or joined together, enabling artists to create larger and more complex sculptures. Overall, aluminum sheets provide artists with a flexible and durable material that allows for creativity and longevity in their sculptural works.

- Q:Can aluminum sheets be formed into seamless tubes or pipes?

- Yes, aluminum sheets can be formed into seamless tubes or pipes. This is typically done through a process called extrusion, where the aluminum sheet is heated and forced through a die to form the desired shape. The extrusion process allows for the creation of seamless tubes or pipes with consistent dimensions and a smooth surface finish. Aluminum is a highly versatile and malleable material, making it suitable for various applications where lightweight and corrosion-resistant tubing is required.

- Q:Are aluminum sheets suitable for architectural roofing?

- Yes, aluminum sheets are suitable for architectural roofing. Aluminum is a lightweight material that is resistant to corrosion, making it an ideal choice for roofing applications. It is also highly durable and can withstand harsh weather conditions, including extreme temperatures, UV radiation, and strong winds. Additionally, aluminum sheets are available in a variety of colors and finishes, allowing for flexibility in design and aesthetics. Moreover, aluminum is a sustainable and environmentally friendly material as it can be recycled indefinitely without losing its properties. Overall, aluminum sheets provide excellent performance and versatility, making them a popular choice for architectural roofing.

- Q:How do aluminum sheets perform in terms of machinability?

- Aluminum sheets are known for their excellent machinability. They can be easily cut, drilled, and shaped using various machining processes. The softness and low melting point of aluminum make it highly conducive to machining operations. Additionally, aluminum sheets exhibit good chip formation and evacuation, resulting in smooth and efficient machining.

- Q:Can aluminum sheets be used for electrical wiring?

- Electrical wiring cannot utilize aluminum sheets. Although aluminum boasts good conductivity, its high electrical resistance renders it unsuitable for such purposes. Copper, on the other hand, is the preferred material for electrical wiring due to its low resistance and superior efficiency in conducting electricity. Moreover, aluminum is susceptible to oxidation, which may result in inadequate conductivity and potential fire risks. Copper wires, on the contrary, are meticulously crafted and produced to comply with electrical safety standards, guaranteeing dependable and secure electrical connections.

- Q:For a high school Chemistry course I made soap for a project. Before doing this, thank god, i learned that one should never use an aluminum container to mix the lye (NaOH) and water. Now, I need to know why. I know it eats away at the container but i can't figure out why. It goes against everything I've learned so far. At first i thought it was because Aluminum was, for some strange reason :o, more reactive than Sodium therefore replacing it in the reaction but that turned out not to be true. Does anyone have an idea of why? Thanks

- Under normal circumstances, aluminum does not react with water, as an impermeable protective layer composed of aluminum hydroxide either forms within seconds or is already in place. With the addition of sodium hydroxide, the formation of a protective layer is prevented. With the production of aluminates [ Al(OH)4 ]-, the amphoteric (capable of acting as either an acid or a base) aluminum hydroxide Al(OH)3 goes in solution: 2 Al + 6 H2O -- 2 Al(OH)3 + 3 H2 Al(OH)3 + NaOH -- Na+ + [ Al(OH)4 ]- A layer of aluminum oxide previously formed by passive corrosion is dissolved by the addition of sodium hydroxide. For this reason, the reaction takes place at the beginning relatively slowly: Al2O3 + 2 NaOH + 3 H2O -- 2 Na+ + 2 [ Al(OH)4 ]- The aluminum completely dissolves and the water acts here too as an acid (for an analog, see Experiment 4.4.1). This reaction is used in drain cleaners. They are mostly made out of strong alkalis, to which alumunim or zinc has been added. The alkalis break down organic residues chemically. In addition, the formation of hydrogen leads to a bubbling effect which adds an additional mechanical cleaning mechanism. The big problem here is the formation of hydrogen gas (as well as some heat). The hydrogen gas is flammable, and if it's in a closed container, will explode

- Q:project on aluminum and i cant think of a good/funny slogan for it! HELP! i have already seen the other possibilities on google, try to be unique, and creative! but if you cant just answer the flipping question PLZ!

- Aluminum: Keeping stoners amazed for over 50 years!

- Q:How do I clean and maintain aluminum sheets?

- In order to clean and maintain aluminum sheets, there are several steps that can be followed: 1. To begin, one should prepare a cleaning solution by combining warm water with a mild detergent or dish soap in a bucket or sink. It is important to avoid using harsh chemicals or abrasive cleaners as they can cause damage to the aluminum. 2. Next, immerse a soft sponge or cloth into the cleaning solution and gently scrub the surface of the aluminum sheets. It is necessary to ensure that the entire surface is covered, with special attention given to any stains or dirt build-up. 3. In the case of stubborn stains or grime, a non-abrasive brush or toothbrush can be used to scrub the affected areas. However, caution should be exercised to prevent applying excessive pressure, as this may result in scratching the aluminum. 4. Following the cleaning process, the sheets should be thoroughly rinsed with clean water to eliminate any residue from the cleaning solution. It is important to ensure that all soap is completely rinsed off. 5. Once rinsed, a clean and dry cloth should be used to remove any excess water and dry the aluminum sheets. This step aids in preventing water spots or stains from forming. 6. To preserve the shine and condition of the aluminum, a thin layer of aluminum polish or wax can be applied. It is advisable to follow the manufacturer's instructions for the best outcomes. 7. Regular inspection of the aluminum sheets is recommended to detect any signs of damage, such as dents, scratches, or corrosion. If any issues are noticed, they should be promptly addressed to prevent further harm. It is crucial to handle aluminum sheets with care to avoid damage. The use of abrasive materials, sharp objects, or harsh chemicals that can scratch or corrode the surface should be avoided. Regular cleaning and maintenance will assist in preserving the appearance and prolonging the lifespan of the aluminum sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Brushed Aluminum Sheet for Sale in All Kinds Alloy Series

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords