Austenitic Seamless Steel Pipe 316L (00Cr17Ni14Mo2)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Austenitic Seamless Steel Pipe 316L Description:

Stainless Steel 316L Pipe is also known as austenitic stainless steel alloy. It offers tremendously high resistance to pitting and crevice corrosion in the chloride conditions. With its austenitic structure it imparts extremely high hardness even at low cryogenic temperature ranges. Stainless Steel 316L Pipe offers stress to rupture, large tensile strength and creeping resistance at the elevated temperature ranges.

2、Main Features of the Austenitic Seamless Steel Pipe 316L :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Excellent weldability

• Highly tough

•Tremendous resistance to corrosion in the various media and oxidation

3、Austenitic Seamless Steel Pipe 316L Images:

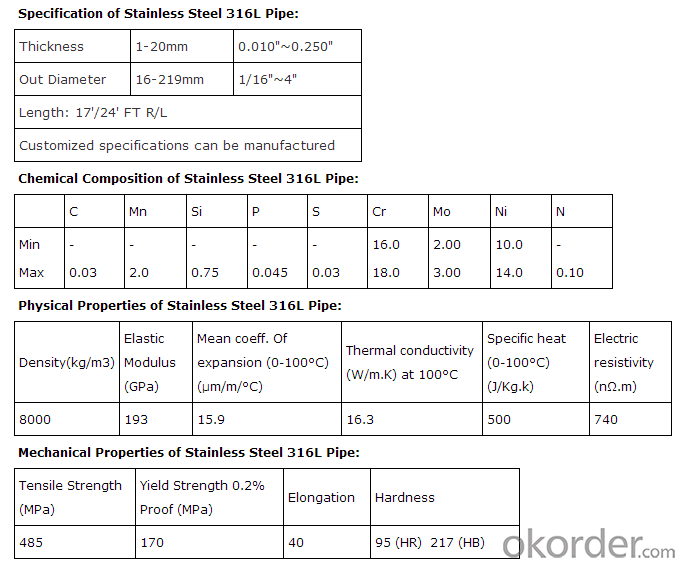

4、Austenitic Seamless Steel Pipe 316L Specification:

Product name: AISI stainless steel pipe/tube

Materials: 304, 304L, 310S, 316, 316L, 325, 273, 219 and 168

Thickness: 1, 2, 2.5, 3, 3.5, 4, 5, 6 and 8mm

Outer diameter: 6-480mm

Length: as required

Treatment: cold and hot rolled

Applications: construction upholstery, and industry instruments, such as fencing, railing,safe doors/windows, gate fittings, inside staircases, balcony balustrades, furniture, sanitary wares and kitchen wares

Standards: GB, AISI, ASTM, DIN and JIS

Sureface: 2B, BA and designer finishes

Price terms: FOB, CIF, CFR and EXW

Delivery:10-15 days after received the deposit or as quantity request.

Chemical Composition | C | Mn | P | S |

<=0.0< span="">3 | <=2.00< span=""> | <=0.0< span="">35 | <=0.03< span=""> | |

Si | Cr | N | Ni | |

<=1.00< span=""> | 16-18 | NO | 12-15 |

5、FAQ of Austenitic Seamless Steel Pipe 316L :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q:Can stainless steel pipes be coated with other materials?

- Coating stainless steel pipes with different materials is indeed possible. It is a widely adopted practice across diverse industries. The aim behind this coating procedure is to elevate their performance, safeguard against corrosion, enhance visual appeal, or provide supplementary functionalities. Epoxy, polyethylene, PVC, zinc, or ceramic coatings are some of the commonly employed materials for coating stainless steel pipes. These coatings offer numerous advantages, including heightened resistance to corrosion, improved resistance against abrasion, enhanced insulation properties, or diminished friction. The process of coating stainless steel pipes with other materials is typically carried out through techniques like electroplating, hot-dipping, or powder coating. The selection of the coating material and process hinges upon the specific requirements and intended application of the stainless steel pipes.

- Q:Why can't stainless steel tubes be cut with acetylene?

- Is mainly from Huoxian, heating flame is mainly open before cutting and cutting plate preheating on the auxiliary heating.Stainless steel, chromium containing at least 13% or more, it hinders the exothermic oxidation and melting phenomenon, which is higher than that of iron chromium to 316 degrees, 1855 degrees, so can not use stainless steel oxygen - acetylene flame cutting.

- Q:How do you join stainless steel pipes to other materials?

- There are various methods available for joining stainless steel pipes to other materials, depending on the specific application and requirements. Below are some commonly used techniques: 1. Welding: The most widely used and effective method for joining stainless steel pipes to other materials is welding. Depending on the material and desired joint strength, different welding processes like TIG welding, MIG welding, or stick welding can be employed. Welding ensures a strong and long-lasting bond between the stainless steel pipes and other materials. 2. Flanges: Flanges are frequently utilized to connect stainless steel pipes to other materials when easy disassembly or connection to different equipment is necessary. Flanges are usually made from materials such as carbon steel, cast iron, or even stainless steel itself. These flanges are bolted together, creating a secure joint that can be easily disconnected, as required. 3. Threaded connections: Threaded connections provide another means of joining stainless steel pipes to other materials. This method is commonly used for smaller diameter pipes or situations where easy removal or replacement of the pipes is needed. Threaded connections can be achieved using pipe fittings like couplings, unions, or adapters, which have male and female threads that screw together to form a tight seal. 4. Compression fittings: Compression fittings are an alternative option for joining stainless steel pipes to other materials. These fittings consist of a compression nut, a ferrule, and a body that houses the ferrule. The ferrule is compressed onto the pipe, creating a tight seal when the compression nut is tightened. Compression fittings ensure a reliable and leak-free joint between stainless steel pipes and other materials. 5. Mechanical connectors: In certain cases, mechanical connectors can be used to join stainless steel pipes to other materials. These connectors typically involve clamping or fastening mechanisms that secure the pipes together without the need for welding or threading. Mechanical connectors are suitable when disassembly and reassembly are required. When selecting the appropriate method to join stainless steel pipes to other materials, it is crucial to consider the specific application, material compatibility, and the required strength and durability of the joint. Consulting with a professional or referring to industry standards and guidelines is recommended to ensure a proper and reliable connection.

- Q:What is the difference between 304H and 316H stainless steel pipes?

- The chemical composition and elements contained in 304H and 316H stainless steel pipes are what sets them apart. 304H stainless steel is a variation of the 304 stainless steel alloy that is specially designed for high-temperature usage. It has a higher carbon content compared to standard 304 stainless steel, which improves its strength and resistance to corrosion at high temperatures. This makes it suitable for environments with elevated temperatures and corrosive substances. On the other hand, 316H stainless steel is a variation of the 316 stainless steel alloy, also intended for high-temperature applications. Like 304H, it has a higher carbon content than standard 316 stainless steel, which enhances its high-temperature strength. However, 316H stainless steel also contains molybdenum, which provides additional corrosion resistance, particularly in environments with chlorides like seawater or marine settings. To summarize, both 304H and 316H stainless steel pipes are suitable for high-temperature applications, but 316H offers better corrosion resistance due to the inclusion of molybdenum. The choice between the two depends on the specific requirements of the application, such as the presence of corrosive substances or chlorides in the environment.

- Q:Are stainless steel pipes resistant to corrosion?

- Yes, stainless steel pipes are highly resistant to corrosion due to the presence of chromium in their composition, which forms a protective layer on the surface of the pipes, preventing rusting and corrosion.

- Q:Are stainless steel pipes suitable for drinking water applications?

- Yes, stainless steel pipes are suitable for drinking water applications. Stainless steel is highly resistant to corrosion, which ensures the water remains free from contaminants. It also has a smooth surface that prevents the accumulation of bacteria or impurities, making it a safe and hygienic choice for transporting drinking water.

- Q:What is the difference between 304J7 and 316J7 stainless steel pipes?

- The main difference between 304J7 and 316J7 stainless steel pipes lies in their composition and properties. 304J7 stainless steel is part of the 304 series, which is a widely used stainless steel grade known for its excellent corrosion resistance and durability. It contains around 18-20% chromium and 8-10% nickel, which contribute to its corrosion resistance and make it suitable for various applications, including plumbing, food processing, and chemical industries. On the other hand, 316J7 stainless steel belongs to the 316 series, which is a higher grade of stainless steel compared to 304. It contains a higher amount of chromium (16-18%) and nickel (10-14%) as well as the addition of molybdenum (2-3%), which further enhances its corrosion resistance, especially against chlorides and other aggressive environments. This makes 316J7 stainless steel pipes ideal for applications such as marine environments, coastal areas, and chemical processing plants. In terms of mechanical properties, 316J7 stainless steel pipes generally have higher tensile strength and creep resistance compared to 304J7. This makes them more suitable for high-pressure and high-temperature applications. Furthermore, 316J7 stainless steel pipes are often considered more expensive than 304J7 due to their superior corrosion resistance and enhanced properties. However, the specific pricing may vary depending on market conditions and other factors. In summary, while both 304J7 and 316J7 stainless steel pipes offer good corrosion resistance, 316J7 is a higher grade with superior resistance to chlorides and aggressive environments. The choice between the two will depend on the specific application requirements, budget, and environmental factors.

- Q:What is the difference between martensitic and precipitation-hardening stainless steel pipes?

- Martensitic and precipitation-hardening stainless steel pipes belong to two distinct categories of stainless steel alloys, each offering unique characteristics and properties. Renowned for their superior strength and hardness, martensitic stainless steel pipes are created through a process known as quenching and tempering. This involves rapidly cooling the material and then reheating it to attain the desired properties. This type of stainless steel is also magnetic and can undergo heat treatment to further bolster its strength. Martensitic stainless steel pipes are commonly utilized in applications requiring exceptional mechanical strength, such as automotive components and cutlery. In contrast, precipitation-hardening stainless steel pipes incorporate elements like copper, aluminum, or titanium into their composition. These additional elements enable the formation of precipitates during heat treatment, resulting in enhanced strength and corrosion resistance. Additionally, precipitation-hardening stainless steel pipes exhibit excellent weldability and can be easily machined. They find extensive application in industries such as aerospace, oil and gas, and chemical processing, where a combination of strength and corrosion resistance is of utmost importance. In summary, the primary distinction between martensitic and precipitation-hardening stainless steel pipes lies in their composition and the heat treatment procedures employed. Martensitic stainless steel pipes are hardened through quenching and tempering, delivering exceptional strength and hardness. Conversely, precipitation-hardening stainless steel pipes derive their strength from the formation of precipitates during heat treatment, providing a well-balanced combination of strength and corrosion resistance.

- Q:What's the difference between cold drawn steel tube and hot rolled steel tube?

- Cold drawn steel tube is a kind of precision cold drawn seamless pipe used for mechanical structure and hydraulic equipment with high dimensional accuracy and good surface finish. The use of precision seamless tube manufacturing machinery structure or hydraulic equipment, etc., can greatly save the working hours of mechanical processing, improve material utilization, at the same time help improve product quality.

- Q:Are stainless steel pipes suitable for power plants?

- Yes, stainless steel pipes are highly suitable for power plants. They offer exceptional resistance to corrosion, high temperatures, and pressure, making them ideal for transporting various fluids and gases within power plants. Additionally, stainless steel pipes have excellent strength and durability, ensuring long-term reliability in the demanding operating conditions of power plants.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Austenitic Seamless Steel Pipe 316L (00Cr17Ni14Mo2)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords