Aluminum Sheet Plate Slab Best Selling Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and cold rolled stainless steel plate and cold rolled stainless steel plate

are sll widely used in the field of is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,O,F, H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

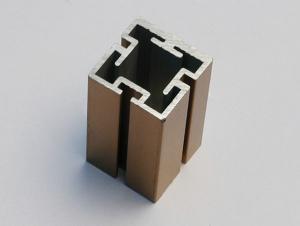

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from vietnam, sri lanka, bangladesh, etc.

ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

stainless steel sheet/plate/slab, etc

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q:Can aluminum profiles be used in green building projects?

- Green building projects can utilize aluminum profiles effectively. Aluminum, being an eco-friendly material, offers numerous advantages in the realm of green building. To begin with, aluminum's lightweight nature cuts down on transportation costs and energy consumption during construction. Furthermore, aluminum is entirely recyclable, ensuring that it can be reused indefinitely without any loss in quality. This characteristic makes aluminum an ideal option for green building projects as it aids in waste reduction and promotes a circular economy. Additionally, aluminum boasts a lengthy lifespan and necessitates minimal upkeep, further enhancing its sustainability. It is worth noting that aluminum profiles can easily be integrated with other green building materials like glass, enabling energy-efficient designs that maximize natural light and minimize the reliance on artificial lighting. In conclusion, aluminum profiles offer a sustainable and versatile choice for green building projects.

- Q:Can aluminum profiles be used for lighting fixtures or systems?

- Yes, aluminum profiles can be used for lighting fixtures or systems. Aluminum is a lightweight and versatile material that is commonly used in the construction of lighting fixtures due to its durability, corrosion resistance, and heat dissipation properties. Aluminum profiles can be easily fabricated into various shapes and sizes, making them suitable for different lighting applications such as recessed lighting, track lighting, pendant lighting, and more. Additionally, aluminum profiles can be anodized or coated with different finishes to enhance their aesthetic appeal and protect them from environmental elements. Overall, the use of aluminum profiles in lighting fixtures or systems allows for efficient and effective lighting solutions while maintaining a sleek and modern design.

- Q:Is aluminum alloy made of industrial aluminum?

- Two, according to the alloy can be divided into 1024 categories: a 2011, 6063, 6061, 6082, 7075 grade aluminum alloy, which is the 6 most common. Grades are different in various metal components ratio is not the same, in addition to the usual windows In addition to aluminum such as the 60 series, 70 series, 80 series, 90 series, curtain wall series aluminum profile, aluminum industry has no clear distinction model, most manufacturers are in accordance with the actual drawings processing customer.

- Q:What is the opening section of aluminum profile?

- Aluminum has an outer outline, an open outline, a closed outline, a plane to cut the opening, the plane is cut.Aluminum: aluminum, made from aluminum and other alloy elements. It is usually processed into casting, forging, and foil, plate, strip, tube, rod, section bar, etc., and then made by cold bending, sawing, drilling, assembling and coloring. The main metal element is aluminum, which is added with some alloying elements to improve the performance of aluminum. Aluminum products classification: rolling material, casting material, non heat treatable alloy, pure Aluminum Alloy (1 * * * Series), Al Cu alloy (2 * * * Series), aluminum manganese alloy (3 * * * Series), aluminum silicon alloy (4 * * * series of aluminum magnesium alloy (,) 5 * * * Series), aluminum magnesium silicon alloy (6 * * * Series), Al Zn Mg alloy (7 * * * Series), aluminum alloy and other elements (8 * * * series).

- Q:Aluminum bending die, iron must be used, what iron should be used, specifically what brand?

- General production of aluminum alloy is H13, die steel, if stretched or squeezed, most are carbide. I work in the production of aluminum profiles

- Q:What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- 5 specific gravity density: under the same volume conditions, magnesium alloy is lighter than aluminum alloy, which is the advantage of magnesium alloy.6 modulus of elasticity: the frame made of magnesium alloy is more rigid than aluminum alloy frame, and the frame made of the same thickness and caliber can absorb more trampling force when riding, which will influence riding efficiency.

- Q:Are there any special considerations for installing aluminum profiles?

- Yes, there are several special considerations for installing aluminum profiles. Firstly, it is important to ensure that the profiles are properly aligned and leveled during installation. This is crucial for achieving a seamless and professional-looking finished product. Using a laser level or a spirit level can help in this process. Secondly, it is essential to use the correct type and size of fasteners when installing aluminum profiles. Stainless steel or aluminum screws or rivets are commonly used, as they are resistant to corrosion and provide a secure hold. Additionally, it is important to pre-drill holes in the profiles to prevent cracking or splitting. Another consideration is the expansion and contraction of aluminum due to temperature changes. Aluminum has a high coefficient of thermal expansion, so it is necessary to leave enough space for the profiles to expand and contract without causing damage. This can be achieved by leaving a small gap between the profiles during installation. Furthermore, it is important to take into account the weight of the profiles and the load they will be subjected to. If the profiles are intended to support heavy loads or structural components, additional support or reinforcement may be required. Lastly, it is crucial to follow the manufacturer's instructions and guidelines for installation. Each type of aluminum profile may have specific requirements, such as recommended installation techniques or maximum spans between supports. Adhering to these guidelines will ensure a safe and secure installation. In conclusion, installing aluminum profiles requires careful attention to alignment, fasteners, expansion and contraction, load considerations, and following manufacturer's instructions. By considering these factors, one can ensure a successful and long-lasting installation.

- Q:How do aluminum profiles perform in fire-resistant structures?

- Aluminum profiles perform exceptionally well in fire-resistant structures due to their inherent fire-resistant properties. Aluminum has a high melting point and does not contribute to the spread of fire, making it a preferred choice for construction materials in fire-resistant structures. Additionally, aluminum profiles maintain their structural integrity even in high temperatures, providing excellent fire protection and ensuring the safety of the building and its occupants.

- Q:The 50 series and the 60 series of aluminum profiles, which one is good?

- respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- Q:Are aluminum profiles resistant to impact?

- Yes, aluminum profiles are generally resistant to impact. Aluminum is known for its high strength-to-weight ratio, meaning it is strong and durable while still being lightweight. This makes it an excellent choice for applications where impact resistance is important, such as in the construction industry for window frames, doors, and curtain walls. Additionally, aluminum profiles can be further enhanced with various surface treatments and coatings to improve their impact resistance even more. However, it is worth noting that the specific impact resistance of an aluminum profile can vary depending on its thickness, design, and any additional reinforcements that may be used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheet Plate Slab Best Selling Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords