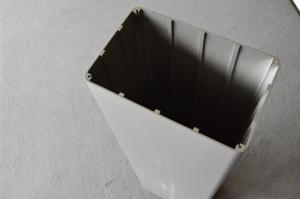

aluminum sections 04

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q:Can aluminum profiles be used in automotive applications?

- Yes, aluminum profiles can be used in automotive applications. Aluminum profiles are lightweight, strong, and corrosion-resistant, making them suitable for various automotive components such as body panels, chassis parts, and engine components. Their use helps reduce the overall weight of the vehicle, improving fuel efficiency and performance.

- Q:Are aluminum profiles painted by powder or by fluorocarbon spray? How can they be distinguished from appearance?

- The surface treatment of the curtain wall aluminum plate is solved by electrostatic spraying, not only the color difference becomes smaller, but also the aluminum plate with various colors can be obtained. Electrostatic spraying can be divided into powder spraying and fluorocarbon spraying. The raw materials of powder spraying are polyurethane, polyurethane resin, epoxy resin, hydroxyl polyester resin and epoxy / polyester resin, which can be made into many colors. The characteristics of powder spraying: spraying equipment manual, automatic hanging type, simple construction, the thickness of the coating is 30 micron, impact resistance, abrasion resistance, corrosion resistance, weather resistance are good, the price cheaper than fluorocarbon coatings.

- Q:Do aluminum profiles require any special maintenance?

- Yes, aluminum profiles require minimal maintenance. They are highly resistant to corrosion and rust, so regular cleaning with mild soap and water is usually sufficient. It is important to avoid using abrasive cleaners or tools that may scratch the surface. Additionally, lubricating moving parts with a silicone-based lubricant can help maintain their smooth operation. Overall, aluminum profiles are relatively low maintenance compared to other materials.

- Q:Can aluminum profiles be used for access control systems?

- Yes, aluminum profiles can be used for access control systems. Aluminum is a versatile and durable material that is commonly used in construction and various industries. It offers excellent strength-to-weight ratio, corrosion resistance, and can be easily shaped and fabricated. When it comes to access control systems, aluminum profiles can be utilized for the construction of doors, frames, and enclosures. These profiles can be designed to accommodate various components such as locks, hinges, control panels, and readers. The lightweight nature of aluminum makes it suitable for door and frame construction, as it allows for easy installation and maintenance. Additionally, aluminum profiles can be finished with different coatings to enhance their appearance and protect them from harsh environmental conditions. Anodizing, for example, can provide a durable and corrosion-resistant surface that can withstand constant use and exposure to the elements. Furthermore, aluminum profiles can be customized to meet specific design requirements. They can be easily cut, drilled, and assembled, allowing for flexibility in creating access control systems that fit the desired aesthetics and functionality. In summary, aluminum profiles are a suitable choice for access control systems due to their strength, lightweight nature, corrosion resistance, and versatility in design. They offer durability and can be easily customized to meet specific requirements, making them a reliable and practical option for securing access points.

- Q:You need is the extrusion machine section now has Liaoning Zhong Wang Liaoyuan Midas Nanshan aluminum aluminum Hunan Sheng Guangxi jungle SWA South northeast light alloy etc. they have more than 4500 tons of extrusion machine mainly produces large section comprises a track body profile LED lamp shell container ship with large cross section conductor rail section I is a seamless tube a market analyst if you have aluminum industrial material need to be aware of the problem you can consult me as friends.

- 4500T is not very large extrusion machine, a little aluminum factory are generally, in the hope of Liaoning, Qinghai Guoxin, Yun ore has more than 10000 tons of production lines, more than sixty percent domestic aluminum production is Guangdong Foshan, there are several manufacturers have the production line, such as Albert, Jianmei so, need to understand the aluminum things to find the best side to understand

- Q:What are the advantages of using aluminum profiles in window and door frames?

- There are several advantages of using aluminum profiles in window and door frames. Firstly, aluminum is a lightweight material, making it easier to handle and install. Additionally, it is highly durable and resistant to corrosion, ensuring long-lasting performance. Aluminum profiles also offer excellent thermal insulation, helping to reduce energy consumption and maintain comfortable indoor temperatures. Moreover, aluminum is highly versatile, allowing for various design options and customization. Finally, aluminum is an environmentally friendly choice, as it is recyclable and has a low carbon footprint.

- Q:What are the different surface protection options available for aluminum profiles?

- There are several surface protection options available for aluminum profiles, depending on the specific requirements and applications. 1. Anodizing: Anodizing is a commonly used surface treatment for aluminum profiles. It involves creating a protective oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides excellent corrosion resistance, durability, and can also enhance the aesthetic appearance of the profiles by offering a range of colors. 2. Powder Coating: Powder coating is another popular surface protection option for aluminum profiles. In this process, a dry powder is electrostatically applied to the surface of the profiles, and then cured under heat to form a protective coating. Powder coating offers excellent durability, resistance to scratches, and comes in a variety of colors and finishes. 3. Painting: Painting is a traditional surface protection method for aluminum profiles. It involves applying a liquid paint coating to the surface, which provides protection against corrosion, UV radiation, and enhances the appearance. Painting allows for a wide range of colors and finishes, making it suitable for various aesthetic requirements. 4. Clear Coating: Clear coating is often used when the natural appearance of the aluminum profiles needs to be preserved while providing protection. This coating forms a transparent film on the surface, protecting it from oxidation, scratches, and other environmental factors, while still showcasing the metallic look of the aluminum. 5. Film Coating: Film coating, also known as protective film or peelable coating, is a temporary surface protection option. It involves applying a thin layer of film onto the aluminum profiles to protect them during transportation, handling, or installation. This film can be easily peeled off after the profiles are installed, leaving a clean and unharmed surface. 6. Mechanical Finishing: Mechanical finishing techniques like brushing, polishing, or sandblasting can be used to improve the surface appearance of aluminum profiles. These methods can help achieve a desired texture, gloss level, or remove any imperfections on the surface. While these techniques do not provide long-term protection, they can be combined with other surface protection options for enhanced aesthetics. Overall, the choice of surface protection option for aluminum profiles depends on factors such as the intended application, desired aesthetics, durability requirements, and cost considerations. It is important to select the most suitable option based on these factors to ensure the longevity and performance of the profiles.

- Q:What are the advantages of using aluminum profiles in the marine industry?

- There are several advantages of using aluminum profiles in the marine industry. Firstly, aluminum is a lightweight material, which allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum is highly resistant to corrosion, making it ideal for marine environments where exposure to saltwater is common. Aluminum profiles also offer excellent strength-to-weight ratio, providing durability and structural stability. Moreover, aluminum is easily recyclable, making it a sustainable choice for the marine industry. Overall, the use of aluminum profiles in the marine industry results in improved performance, longevity, and environmental benefits.

- Q:Can aluminum profiles be used for security doors and windows?

- Yes, aluminum profiles can be used for security doors and windows. Aluminum is a lightweight and durable material that can withstand force and resist corrosion. It can be customized to include additional security features such as multi-point locking systems, reinforced frames, and impact-resistant glass. Additionally, aluminum profiles offer a sleek and modern appearance, making them a popular choice for security doors and windows in residential and commercial properties.

- Q:Can aluminum profiles be used in marine vessel manufacturing?

- Marine vessel manufacturing can indeed utilize aluminum profiles. Boats and other marine vessels are commonly constructed using aluminum due to its exceptional characteristics. Lightweight, durable, and resistant to corrosion, aluminum proves to be an ideal material for marine environments. It can endure the effects of saltwater exposure, a prevalent concern in marine applications. Moreover, aluminum profiles can be effortlessly shaped, welded, and interconnected, facilitating efficient and customizable vessel designs. This adaptability renders aluminum highly appealing to boat builders and manufacturers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

aluminum sections 04

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords