Aluminum Profile For Led Strip Light And Length Customed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminum Profile For Led Strip Light And Length Customed Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile For Led Strip Light And Length Customed:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

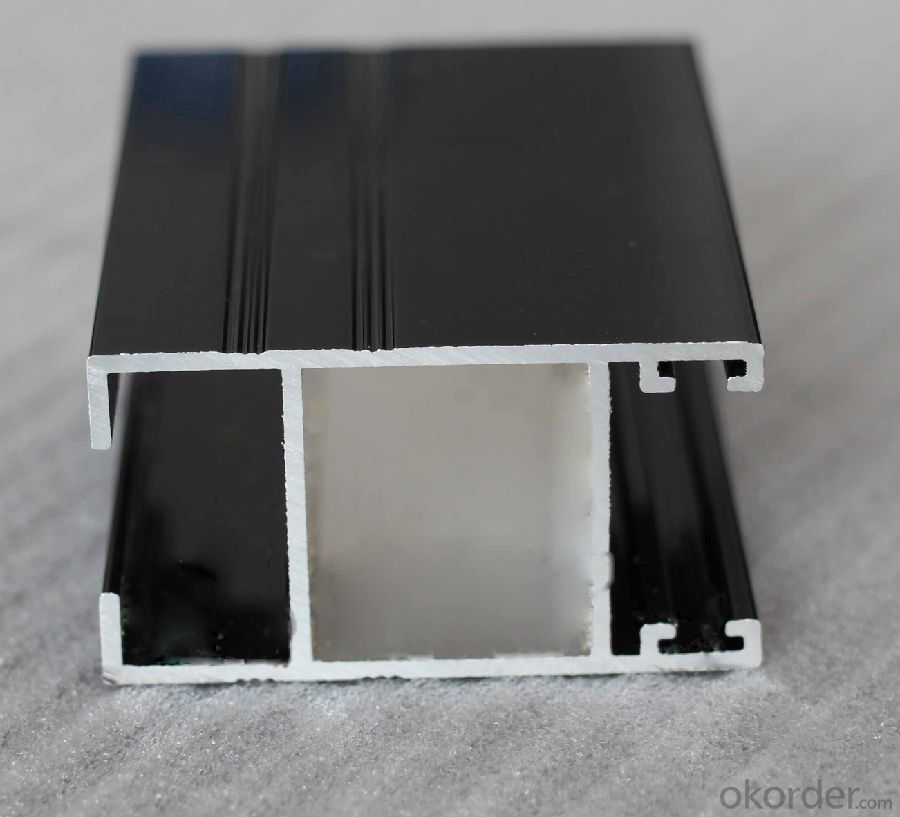

3.Aluminum Profile For Led Strip Light And Length Customed Images:

4.Aluminum Profile For Led Strip Light And Length Customed Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q:What are the specifications of aluminium alloy door and window profiles?

- The aluminum alloy door and window profiles of the same size series are quite complex in shape and size. Must be analyzed and treated in accordance with the drawings.The section of aluminum door and window profile is divided into solid section and hollow section according to the shape of section, and the application of hollow profile is larger.Aluminum door and window profiles of wall thickness, for aluminum alloy window of not less than 1.4mm, with aluminum alloy door is not less than 2mm.The length, size, dividing ruler, double ruler and indefinite ruler of aluminum door and window profiles are three kinds. Fixed length generally not more than 6m, variable length is not less than 1m.

- Q:What is the difference between the two, or how to distinguish it from the outdoor curtain wall?

- Aluminum material refers to the blank material, which is used directly without artificial aging

- Q:What are the different types of aluminum alloys used for profiles?

- There are several different types of aluminum alloys that are commonly used for profiles. Some of the most common types include: 1. 6061 Aluminum Alloy: This alloy is one of the most versatile and widely used aluminum alloys. It offers a good combination of strength, weldability, and corrosion resistance. It is commonly used in structural applications and for making frames, railings, and automotive parts. 2. 6063 Aluminum Alloy: This alloy is known for its excellent formability and extrudability, making it ideal for producing profiles. It offers good corrosion resistance and can be easily shaped into complex designs. It is commonly used for architectural applications, such as window frames, door frames, and curtain walls. 3. 7075 Aluminum Alloy: This alloy is known for its high strength-to-weight ratio and excellent fatigue strength. It is commonly used in aerospace applications and for making high-performance products such as bicycle frames and sporting goods. 4. 5083 Aluminum Alloy: This alloy is primarily used in marine applications due to its excellent corrosion resistance in saltwater environments. It is commonly used for boat hulls, decks, and other marine structures. 5. 3003 Aluminum Alloy: This alloy is known for its good formability, corrosion resistance, and weldability. It is commonly used in general-purpose applications, such as signage, electrical enclosures, and kitchenware. These are just a few examples of the different types of aluminum alloys used for profiles. The selection of the alloy depends on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost.

- Q:How is the price of aluminum profile calculated?

- General Factory aluminum prices are in accordance with the composition of component models of aluminum ingot price plus processing fees in the form of the aluminum price is reference price (the South China Sea coastal area informed factory according to the settlement price) or the Yangtze River (the mainland manufacturers in accordance with the price of aluminum ingots, aluminum price settlement price) every day is not the same, can check on the Internet to the price of aluminum ingots (holidays are closed, no aluminum price), and processing fees for each plant according to surface treatment you need and pricing, general spraying at around 4500, around 5500 (compared with ordinary electrophoresis but also can plant, GB material processing fee).

- Q:Can aluminum profiles be an alternative to steel or iron?

- Aluminum profiles offer a viable alternative to steel or iron in numerous applications due to their lightweight, durability, and exceptional resistance to corrosion. These qualities make them suitable for diverse industries like construction, automotive, aerospace, and electrical. Unlike steel or iron, aluminum exhibits a high strength-to-weight ratio, enabling it to provide equivalent strength while being significantly lighter. Consequently, aluminum profiles are easier to handle, transport, and install, resulting in reduced overall costs. Moreover, aluminum profiles can be easily extruded into intricate shapes, allowing for design flexibility and customization. Nevertheless, it is crucial to acknowledge that aluminum profiles might not be suitable for all applications requiring the high strength or hardness offered by steel or iron. Hence, the decision between aluminum, steel, or iron profiles will rely on the specific requirements of the project or product.

- Q:What are the advantages of industrial aluminum profiles? What are the problems that should be paid attention to?

- Aluminum profile is the aluminum bar through different degrees of hot melt, extrusion, so that it forms different shapes of aluminum materials, aluminum profiles are widely used, often used in construction, home improvement, industry and so on.

- Q:How do aluminum profiles compare to other materials like steel or wood?

- Aluminum profiles offer several advantages over materials like steel or wood. Firstly, aluminum is lightweight, making it easier to handle and transport. Secondly, aluminum is resistant to corrosion, unlike steel, which can rust over time. Additionally, aluminum profiles have a high strength-to-weight ratio, making them durable and ideal for various applications. Lastly, aluminum is highly recyclable, making it a more sustainable choice compared to wood or steel.

- Q:Can aluminum profiles cross Luo? Why is the appearance of an aluminum profile component of a Japanese original machine extremely close to that of Luo Luo? Why? Why?

- Luoyang City days Feng Aluminum Co. Ltd. was founded in 2007, is located in the Luoyang world cultural heritage Longmen Grottoes in southern Yichuan County Bai Yuan Xiang Xia Bao Industrial Park, east of Beijing Guangzhou Jiaozhitielu, West luoluan fast channel, north of Los, Zhengshao, Lianhuo expressway entrance, the position is superior, the transportation is convenient, is one of the the Central Plains aluminum production largest manufacturers.The company has a total investment of RMB 600 million yuan, covering an area of 96000 square meters, and has 96 employees, including 18 technicians and management personnel, and the finance is included in the microcomputer managementThe company in Yichuan County, Xin'an County two national electrolytic aluminum production base, production of industrial aluminum profiles, civil building materials and design of electrophoresis aluminum, the annual output of 50 thousand tons, the construction in two phases, the first phase of the project investment of 600 million yuan, the company has invested more than 2000 yuan, at present, and some office building the factory, the warehouse has been built and put into use, the project construction procedures have been improved.

- Q:Why should aluminum surface treatment process?

- The hard oxide film formed after the surface oxidation treatment prevents the internal aluminum from being oxidized and prolongs the service life of the aluminum profile.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Profile For Led Strip Light And Length Customed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords