All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do aluminum profiles contribute to the production of lightweight and fuel-efficient railway cars and buses?

Aluminum profiles contribute to the production of lightweight and fuel-efficient railway cars and buses by providing a strong yet lightweight material for constructing the structural framework of these vehicles. Due to its high strength-to-weight ratio, aluminum profiles allow for the reduction of overall vehicle weight, resulting in improved fuel efficiency. Additionally, aluminum's corrosion resistance properties ensure the longevity and durability of the railway cars and buses, further enhancing their overall efficiency and performance.

How does the extrusion process contribute to the manufacturing of aluminum profiles?

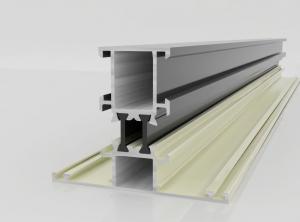

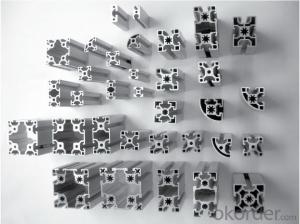

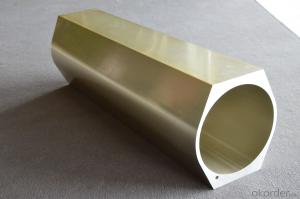

The extrusion process plays a crucial role in the manufacturing of aluminum profiles. It involves pushing or pulling a heated aluminum billet through a shaped die to create a desired cross-sectional shape. This process allows for the production of complex profiles with consistent dimensions and high precision. It also enables the creation of profiles with various lengths, making it highly versatile for different applications in industries such as construction, automotive, and aerospace. Additionally, the extrusion process offers cost-effective production, as it minimizes material waste and requires less machining compared to other manufacturing methods. Overall, extrusion is essential in meeting the demand for aluminum profiles by providing efficient, customizable, and sustainable solutions.

Can you explain the corrosion resistance of aluminum profiles in detail?

Aluminum profiles possess excellent corrosion resistance due to the formation of a protective oxide layer on their surface. When exposed to oxygen in the atmosphere, aluminum reacts to form a thin layer of aluminum oxide. This oxide layer is highly stable and acts as a barrier, preventing further corrosion of the metal beneath it. The oxide layer is transparent, allowing the natural metallic appearance of the aluminum to be retained. Additionally, aluminum profiles can also be further enhanced with various surface treatments, such as anodizing or powder coating, to provide even greater resistance against corrosion in different environments. Overall, the corrosion resistance of aluminum profiles is a result of the unique properties of aluminum and the formation of the protective oxide layer.

Wholesale Aluminum Profiles from supplier in Uzbekistan

Our team of professionals is dedicated to providing excellent customer service and ensuring that your needs are met. Whether you are in need of standard aluminum profiles or customized solutions, we can assist you in finding the right products for your specific requirements.

We understand the importance of timely delivery and strive to ensure that your orders are processed and delivered efficiently. Our strong logistics network enables us to deliver products to any location in Uzbekistan, no matter how remote.

Technical support is another area where we excel. Our team of experts is available to provide guidance and assistance throughout your project, from initial design to installation. We can help you choose the right aluminum profiles for your application and provide technical specifications to ensure optimal performance.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This allows us to offer competitive pricing without compromising on quality. We are committed to providing you with the best value for your investment.

We pride ourselves on our commitment to customer satisfaction and strive to build long-term partnerships with our clients. Whether you are a small business or a large corporation, we are here to meet your aluminum profiles needs in Uzbekistan. Contact us today to discuss your requirements and let us be your trusted supplier of aluminum profiles.

We understand the importance of timely delivery and strive to ensure that your orders are processed and delivered efficiently. Our strong logistics network enables us to deliver products to any location in Uzbekistan, no matter how remote.

Technical support is another area where we excel. Our team of experts is available to provide guidance and assistance throughout your project, from initial design to installation. We can help you choose the right aluminum profiles for your application and provide technical specifications to ensure optimal performance.

As a subsidiary of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and resources. This allows us to offer competitive pricing without compromising on quality. We are committed to providing you with the best value for your investment.

We pride ourselves on our commitment to customer satisfaction and strive to build long-term partnerships with our clients. Whether you are a small business or a large corporation, we are here to meet your aluminum profiles needs in Uzbekistan. Contact us today to discuss your requirements and let us be your trusted supplier of aluminum profiles.