All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

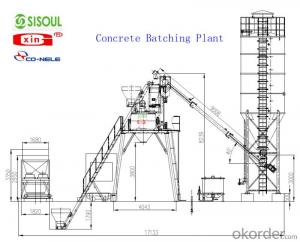

How does a concrete mixing plant work?

A concrete mixing plant works by combining various ingredients like cement, water, aggregates, and additives in predetermined proportions to produce concrete. These ingredients are first stored in different compartments or bins. Then, they are fed into a mixing unit, usually a twin-shaft mixer, where they are blended together to form a homogeneous mixture. The mixing process can be controlled for a specific duration to achieve the desired consistency and quality of concrete. Once the mixing is complete, the concrete is discharged from the mixer and can be transported to construction sites using trucks or conveyor belts.

How do you ensure proper concrete compaction with concrete machinery?

Proper concrete compaction with concrete machinery can be ensured by using the right equipment and techniques. Firstly, selecting the appropriate concrete vibrator or compactor for the specific project is crucial. The machine should have sufficient power and frequency to effectively consolidate the concrete.

Secondly, it is important to follow a systematic approach while compacting the concrete. The machinery should be operated in a way that ensures even distribution of vibration or compaction throughout the concrete. This can be achieved by moving the machine in a grid pattern and overlapping each pass.

Additionally, attention should be paid to the timing of compaction. It is essential to start the process as soon as possible after the concrete is poured to prevent the formation of voids or weak spots. Compaction should continue until all air bubbles are eliminated and the concrete surface appears smooth and uniform.

Regular inspection of the concrete during compaction is necessary to identify any areas that require additional attention. If any voids or inconsistencies are observed, the machinery should be used to re-compact those sections.

Overall, ensuring proper concrete compaction with concrete machinery involves the proper selection and operation of equipment, systematic application of vibration or compaction, timely initiation of the process, and continuous inspection to address any potential issues.

How to choose the right concrete reclaimer for specific needs?

Choosing the right concrete reclaimer for specific needs involves considering factors such as the volume of concrete waste generated, the space available for installation, the desired level of automation, and the budget. Additionally, evaluating the reclaimer's capacity, efficiency, maintenance requirements, and compatibility with existing equipment should be taken into account. Conducting thorough research, seeking advice from industry professionals, and comparing different models will help ensure the selection of a concrete reclaimer that best meets the specific needs and requirements of the project.

What is a concrete curb machine for sale?

A concrete curb machine for sale is a specialized piece of equipment used in construction to create curbs and gutters made of concrete. This machine is designed to efficiently and accurately shape and form the concrete into the desired curb shape, making it easier and faster for construction projects to create durable and functional curbs.

Wholesale Concrete Machinery from supplier in Uzbekistan

Our Concrete Machinery products are sourced from reputable manufacturers and are known for their durability, efficiency, and performance. Whether you need concrete mixers, concrete batching plants, concrete pumps, or other types of concrete machinery, we have a wide range of options available to suit your specific requirements.

In addition to supplying high-quality products, we also offer comprehensive sales, quotation, and technical support services. Our team of experts is available to assist you with product selection, provide detailed quotations, and offer technical guidance throughout your project. We understand the importance of timely and accurate information, and we strive to provide prompt and reliable support to our customers.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide convenient and efficient one-stop procurement services. We have established strong partnerships with manufacturers, ensuring competitive pricing and reliable product availability. Our extensive network and logistical expertise enable us to deliver products to any location in Uzbekistan, ensuring a seamless procurement process for our customers.

With our years of experience in the Uzbekistan market, we have developed a deep understanding of the local construction industry. We are familiar with the regulatory requirements, industry standards, and market dynamics in Uzbekistan, allowing us to offer tailored solutions and guidance. Whether you are starting a new project or expanding an existing one, we can provide valuable insights and recommendations to help you achieve success.

At our company, customer satisfaction is our top priority. We are committed to delivering exceptional customer service and building long-term relationships with our clients. Our team is dedicated to understanding your needs and working closely with you to meet your project goals. From initial inquiry to after-sales support, we are here to assist you every step of the way.

Choose us as your trusted Concrete Machinery supplier in Uzbekistan and experience the difference our expertise can make. Contact us today to discuss your specific requirements and let us help you find the perfect solution for your Concrete Machinery needs.

In addition to supplying high-quality products, we also offer comprehensive sales, quotation, and technical support services. Our team of experts is available to assist you with product selection, provide detailed quotations, and offer technical guidance throughout your project. We understand the importance of timely and accurate information, and we strive to provide prompt and reliable support to our customers.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide convenient and efficient one-stop procurement services. We have established strong partnerships with manufacturers, ensuring competitive pricing and reliable product availability. Our extensive network and logistical expertise enable us to deliver products to any location in Uzbekistan, ensuring a seamless procurement process for our customers.

With our years of experience in the Uzbekistan market, we have developed a deep understanding of the local construction industry. We are familiar with the regulatory requirements, industry standards, and market dynamics in Uzbekistan, allowing us to offer tailored solutions and guidance. Whether you are starting a new project or expanding an existing one, we can provide valuable insights and recommendations to help you achieve success.

At our company, customer satisfaction is our top priority. We are committed to delivering exceptional customer service and building long-term relationships with our clients. Our team is dedicated to understanding your needs and working closely with you to meet your project goals. From initial inquiry to after-sales support, we are here to assist you every step of the way.

Choose us as your trusted Concrete Machinery supplier in Uzbekistan and experience the difference our expertise can make. Contact us today to discuss your specific requirements and let us help you find the perfect solution for your Concrete Machinery needs.