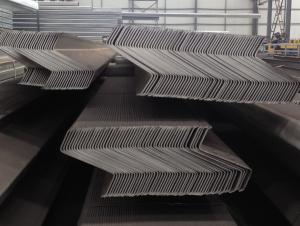

Aluminum frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A).Features:

(1).35*35 suitable for 80-180w solar modules

(2).40*35 suitable for 30-120w solar modules

(3).50*35 suitable for 160-220w solar modules

(4).Many more other sizes such as: 25*35,30*35,46*40,50*35 etc, all the sizes according to customer's requierments.

Common specifications:

620*286*30mm

754*669*30mm

824*545*30mm

1200*545*35mm

B).Two types:

(1) 90°-Angle

(2)45° -Angle

C)Suface Treatment

(1). Anodizing:(Clear,silver,golden,bronze,other muiticolar.)

(2). Electrophoresis

(3). Powder,polishing,PVDF,Sandblasting,etc

Standard: GB/75237-2004,Q/320281/PDWD-2008

Certification: ISO9001:2008

Specifications: According to your design drawings and your samples

Atavantage of our products:

1.Quality-assured products, fully accredited by ISO9001 and "National Inspection-free produt".

2.The productcts are manufactured by first-class automatized equipment and and advanced quality inspection&test facilities.Die excellent accuracy up to 0.02mm.

3.High weather resistance anti scrach anticorrosion and good wearer resistance subtle edges and eligent appearance and eazy processing and installationn high brightness and hardness.

4.Wide variety of styles and sizes suitable for any tastes and budgets

- Q:Can a solar mounting system be used with solar-powered irrigation systems?

- Yes, a solar mounting system can be used with solar-powered irrigation systems. The solar mounting system provides a secure and stable platform for installing the solar panels used to power the irrigation system. It helps to maximize the exposure of the panels to sunlight, ensuring optimal energy production for the irrigation system.

- Q:Can a solar mounting system be used in areas with limited access to weather monitoring systems?

- Yes, a solar mounting system can still be used in areas with limited access to weather monitoring systems. While weather monitoring systems can provide valuable data for optimizing solar energy production and system performance, they are not mandatory for the installation and functionality of a solar mounting system. Solar panels can still be installed and generate electricity in areas with limited access to weather monitoring systems, although the system's overall performance optimization may be more challenging without real-time weather data.

- Q:Are there any specific requirements for canopy design when using a solar mounting system for canopies?

- Yes, there are specific requirements for canopy design when using a solar mounting system. These requirements include factors such as the structural integrity of the canopy to withstand the weight and wind loads of the solar panels, proper orientation and tilt angle for maximum solar exposure, sufficient space for panel installation and maintenance, and compatibility with electrical wiring and connection points. Additionally, consideration should be given to factors like shading and clearance to ensure optimal performance of the solar system.

- Q:Are there any specific requirements for installing a solar mounting system on a rooftop with a rooftop garden?

- Yes, there are certain requirements for installing a solar mounting system on a rooftop with a rooftop garden. Firstly, the rooftop should have sufficient load-bearing capacity to support both the solar panels and the weight of the garden. It is also important to ensure that the mounting system does not damage the rooftop garden or its irrigation system during installation. Additionally, adequate space should be available to accommodate both the solar panels and the garden without compromising their functionality or efficiency. Lastly, it is crucial to consider any local regulations or permits that may be required for rooftop solar installations with a rooftop garden.

- Q:How does a solar mounting system affect the roof's thermal insulation?

- A solar mounting system can have both positive and negative effects on a roof's thermal insulation. On one hand, the installation of solar panels can provide an added layer of insulation to the roof, reducing heat transfer and potentially improving energy efficiency. On the other hand, the mounting system may create penetration points in the roof, which can compromise its thermal insulation if not properly sealed or insulated. Therefore, it is crucial to ensure that the solar mounting system is installed correctly to minimize any potential negative impact on the roof's thermal insulation.

- Q:Can a solar mounting system be used on asbestos roofs?

- Yes, a solar mounting system can be used on asbestos roofs. However, it is important to ensure that proper safety measures are followed during installation to prevent any disturbance or release of asbestos fibers. It is recommended to consult with professionals experienced in working with asbestos roofs to ensure compliance with safety regulations and guidelines.

- Q:Can a solar mounting system be used with solar-powered camping equipment?

- Yes, a solar mounting system can be used with solar-powered camping equipment. The mounting system allows for easy installation and positioning of solar panels, which can then be used to power various camping equipment such as lights, chargers, and portable fans. This setup provides a sustainable and convenient solution for accessing renewable energy while camping.

- Q:What is the expected payback period for a solar mounting system?

- The expected payback period for a solar mounting system can vary depending on factors such as the initial cost, energy savings, and local incentives. However, on average, it typically ranges from 5 to 10 years.

- Q:Can a solar mounting system be installed on a boat or yacht?

- Yes, a solar mounting system can be installed on a boat or yacht.

- Q:Are there any disadvantages to using a solar mounting system?

- Yes, there are a few disadvantages to using a solar mounting system. Firstly, the installation cost of a solar mounting system can be quite high, especially for larger installations. Additionally, the system requires regular maintenance to ensure optimal performance, which can add to the overall cost. Furthermore, the positioning and angle of the panels are crucial for maximum efficiency, so if there are obstructions or shading in the surrounding area, it can significantly reduce the system's output. Lastly, extreme weather conditions such as strong winds or heavy snow can pose a risk to the structural integrity of the mounting system if it is not properly designed and installed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords