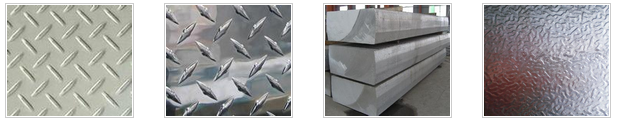

Aluminium Tear Plates, Bright Diamond

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Tear Plates, Bright Diamond :

Aluminium Tear Plates, Bright Diamond is widely used for decorative purposes in construction, packing and appliance. Aluminium Tear Plates, Bright Diamond is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of Aluminium Tear Plates, Bright Diamond :

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminium Tear Plates, Bright Diamond

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4. Production of Aluminium Tear Plates, Bright Diamond

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q:What is an aluminum sheet?

- An aluminum sheet refers to a flat, thin piece of aluminum that is usually rectangular in shape. It is commonly used in various industries and applications due to its lightweight, durability, and corrosion resistance properties. Aluminum sheets can be easily manipulated, cut, and formed into different shapes to meet specific requirements in construction, automotive, aerospace, and manufacturing sectors.

- Q:What are the different alloys used in aluminum sheets?

- There are several different alloys used in aluminum sheets, each with its own unique properties and characteristics. Some of the commonly used alloys are: 1. 1100: This alloy is known for its excellent corrosion resistance and high electrical conductivity. It is often used in applications requiring a high level of formability and weldability, such as food packaging and electrical conductors. 2. 3003: This alloy is widely used in various applications due to its good formability, moderate strength, and excellent corrosion resistance. It is commonly used in cooking utensils, chemical equipment, and general sheet metal work. 3. 5052: This alloy is known for its high strength and good corrosion resistance. It is often used in marine applications, as well as in aircraft fuel tanks and automotive parts. 4. 6061: This alloy is one of the most versatile and widely used aluminum alloys. It offers excellent corrosion resistance, good weldability, and moderate strength. It is commonly used in structural components, such as frames and railings, as well as in automotive parts and aerospace applications. 5. 7075: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is often used in applications requiring extreme strength, such as aircraft and aerospace components, as well as in high-performance sporting goods. These are just a few examples of the many different alloys used in aluminum sheets. The choice of alloy depends on the specific application requirements, such as strength, corrosion resistance, formability, and weldability.

- Q:Can aluminum sheets be custom cut to specific sizes?

- Yes, aluminum sheets can be custom cut to specific sizes according to the requirements of the project or application.

- Q:Are the aluminum sheets suitable for manufacturing automotive body panels?

- Yes, aluminum sheets are suitable for manufacturing automotive body panels. Aluminum is a lightweight yet strong material that offers several advantages for automotive applications. Its high strength-to-weight ratio allows for improved fuel efficiency and better overall performance of the vehicle. Aluminum also has excellent corrosion resistance, making it suitable for withstanding harsh environmental conditions. Additionally, it can be easily formed and manipulated, allowing for complex designs and shapes required for automotive body panels. These characteristics make aluminum sheets a popular choice in the automotive industry for manufacturing body panels.

- Q:Is this aluminium plate ceiling dark keel or bright keel?

- I see you're a layman...... Where is the ceiling keel now?.... Now they are made of dark keel, so it's better to look at comfort, and we need to go through the lines and some pipes

- Q:Are aluminum sheets suitable for electrical conductors?

- Yes, aluminum sheets are suitable for electrical conductors. Aluminum is often used as a conductor in various electrical applications due to its excellent conductivity, lightweight nature, and relatively low cost compared to other metals like copper. It has approximately 61% conductivity of copper, making it an efficient conductor for most electrical purposes. Aluminum sheets are commonly used in power transmission lines, electrical wiring, bus bars, and numerous other electrical components. However, it is important to note that aluminum has a higher resistance compared to copper, which means it may require larger cross-sections to carry the same current. Additionally, aluminum has a lower melting point than copper, so proper care must be taken to avoid overheating when using aluminum sheets as electrical conductors.

- Q:Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves punching holes or creating a pattern of holes in a material. Aluminum is a versatile and malleable metal that can be easily perforated using various methods such as punching, drilling, or laser cutting. Perforating aluminum sheets can serve multiple purposes such as allowing for airflow, reducing weight, enhancing aesthetics, or creating filtration systems. The size, shape, and arrangement of the perforations can be customized to meet specific requirements and design preferences. Overall, aluminum sheets can be effectively perforated to enhance their functionality and visual appeal.

- Q:Which kind of glue is best for bonding wood and aluminum sheet together?

- You can use 502 adhesive.

- Q:How do you prevent oil or grease stains on aluminum sheets?

- One effective way to prevent oil or grease stains on aluminum sheets is to apply a protective coating or finish. This can be done by using a specialized oil-resistant sealant, such as a clear lacquer or anodizing the aluminum. Additionally, maintaining a clean and dry surface, regularly wiping away any spills or residue, and using non-greasy or oil-free tools and equipment can help minimize the chances of stains occurring.

- Q:Are aluminum sheets suitable for signage?

- Signage can greatly benefit from the use of aluminum sheets. This material is known for its versatility and numerous advantages when it comes to signage applications. With its lightweight nature, durability, and resistance to corrosion, aluminum is an excellent choice for both indoor and outdoor signage. Regardless of weather conditions, be it rain, snow, or intense UV exposure, aluminum sheets will not deteriorate or fade. Furthermore, aluminum sheets are easy to work with, providing a wide range of customization options such as embossing, engraving, and digital printing. Not only are they cost-effective, but they also have a long lifespan, ensuring that signage remains in top-notch condition for extended periods. Ultimately, due to their durability, versatility, and aesthetic appeal, aluminum sheets are a preferred choice for signage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Tear Plates, Bright Diamond

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords