Aluminium Sheet With Hot Rolled With Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Product Description

Our aluminum sheet/plate/slab is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1060,5052,5083,6061,7075, 8011, etc.

The temper is include H14,H24, H44,H112,O, H112, etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

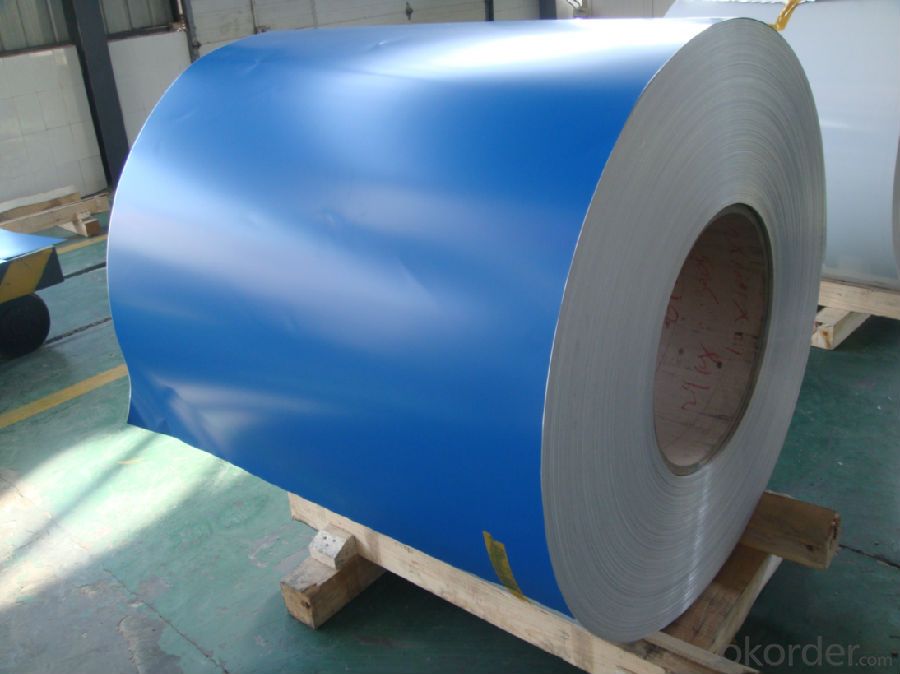

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm, 1220mm*2440mm,etc.

5. FAQ:

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---UAE, USA, Canada, Fiji, Turkey, South Africa, etc.

what is your mainly products?

---Normally they are aluminum sheet,checkered sheet, checkered plate, checkered slab,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q:what's the difference between zinc sheet and aluminum sheet?

- Only the zinc sheet reacts after adding concentrated nitric acid in drops ,zinc is amphoteric.

- Q:What are the different methods of bending aluminum sheets?

- There are several methods of bending aluminum sheets, each with its own advantages and limitations. Some of the commonly used methods include: 1. Press Brake Bending: This method involves clamping the aluminum sheet between a punch and a die on a press brake machine. The sheet is then bent by applying force through the punch, which pushes against the die. Press brake bending is ideal for high-volume production and can achieve precise and consistent bends. 2. Roll Bending: Also known as a three-roll bending process, this method uses a set of three rollers to gradually bend the aluminum sheet into the desired shape. Roll bending is suitable for creating cylindrical or conical shapes and is often used in industries like automotive and aerospace. 3. Stretch Bending: In this method, the aluminum sheet is clamped at both ends while a stretching force is applied in the middle. The sheet is elongated and bent simultaneously, resulting in a curved shape. Stretch bending is commonly used for producing curved profiles with a smooth and uniform finish. 4. Heat Bending: By applying heat to the aluminum sheet, it becomes more pliable and can be easily bent into desired shapes. Heat bending is often performed using a heat gun or an oven to soften the metal, followed by manual or mechanical bending. This method is useful for creating complex and intricate shapes. 5. Incremental Bending: This method involves bending the aluminum sheet in multiple steps or increments, gradually increasing the bend angle with each step. Incremental bending allows for greater control over the bending process and is commonly used for forming U-shaped or V-shaped bends. 6. Roll Forming: In roll forming, the aluminum sheet is fed through a series of rollers, each gradually bending the sheet a little more. This continuous process is ideal for producing long and consistent bends, often used in the production of aluminum profiles and extrusions. It is worth noting that the choice of bending method depends on factors like the desired bend angle, the thickness and grade of the aluminum sheet, the required precision, and the volume of production.

- Q:What are the different methods of surface preparation for aluminum sheets?

- Aluminum sheets can undergo various surface preparation methods to ensure optimal adhesion and paint durability. Below are different techniques for preparing aluminum surfaces: 1. Utilizing Mechanical Abrasion: This method involves physically eliminating any dirt, rust, or oxidation from the aluminum surface using materials like sandpaper, wire brushes, or sandblasting. Mechanical abrasion creates a rough texture that enhances paint adhesion. 2. Employing Chemical Cleaning: Chemical cleaning employs acidic or alkaline solutions to eliminate contaminants or oxidation from the aluminum surface. This technique is particularly effective for tough stains, oils, or greases. After chemical cleaning, thorough rinsing removes any residue. 3. Implementing Etching: Etching entails applying an acidic or alkaline solution to create a microscopically rough texture on the aluminum surface. This roughness improves paint adhesion and provides a better bonding surface for coatings. Etching is commonly used as a pre-treatment before applying primers or paints. 4. Applying Conversion Coating: Conversion coating involves applying a chemical solution to create a thin, protective layer on the aluminum surface. This layer not only enhances paint adhesion but also provides corrosion resistance. Examples of conversion coatings for aluminum include chromate conversion coatings and phosphoric acid anodizing. 5. Performing Mechanical Cleaning: Mechanical cleaning involves brushing, scraping, or buffing to remove loose particles, dirt, or debris from the aluminum surface. This method is often used as an initial step before applying other surface treatments or coatings. It is crucial to note that the choice of surface preparation method may vary based on the aluminum sheet's specific requirements, surface condition, and desired finish. Proper surface preparation is essential for ensuring the longevity and performance of the applied paint or coating on aluminum sheets.

- Q:What is the surface finish of 101 aluminum sheets?

- The surface finish of 101 aluminum sheets can vary depending on the specific manufacturing process and desired application. However, common surface finishes for 101 aluminum sheets include mill finish, brushed finish, anodized finish, and painted finish. Mill finish refers to the raw, untreated surface of the aluminum sheet, which may have some minor imperfections or scratches. Brushed finish is achieved by brushing the surface of the sheet with a fine abrasive material, resulting in a smooth, satin-like appearance. Anodized finish involves an electrochemical process that forms a protective oxide layer on the surface of the aluminum, providing enhanced durability and corrosion resistance. Painted finish, on the other hand, involves applying a layer of paint onto the aluminum sheet to provide color and additional protection. Ultimately, the choice of surface finish for 101 aluminum sheets depends on the desired aesthetic, functional, and environmental requirements of the application.

- Q:What are the safety precautions when working with aluminum sheet?

- To ensure your well-being and reduce the likelihood of accidents or injuries, it is essential to observe specific safety measures when working with aluminum sheet. Consider the following precautions: 1. Personal Protective Equipment (PPE): Safeguard yourself against potential hazards by wearing appropriate PPE, such as safety glasses, gloves, and a long-sleeved shirt. Aluminum shavings can cause injuries if they come into contact with your skin due to their sharpness. 2. Ventilation: Work in a well-ventilated area or employ local exhaust ventilation systems to prevent the accumulation of fumes and dust. Inhalation of large quantities of aluminum dust or fumes can be harmful. 3. Fire safety: As aluminum is highly flammable, it is crucial to keep flammable materials away from the work area. Ensure you have a fire extinguisher readily available and know how to use it in case of emergencies. 4. Tool safety: Verify that all tools and equipment used for cutting, bending, or shaping aluminum are in good working condition. Accidents are more likely to occur with dull or damaged tools. Follow proper tool handling techniques and avoid using excessive force to minimize the risk of injuries. 5. Proper handling: When moving or lifting aluminum sheets, employ correct lifting techniques and seek assistance if needed. Improper handling can lead to strains or muscle injuries due to the weight of the sheets. 6. Electrical safety: If electrical tools or equipment are utilized, make sure they are properly grounded and in good working order. Avoid using damaged or frayed cords and keep them away from moisture sources. 7. Storage: Store aluminum sheets in a designated area, away from heat sources or flammable materials. Stack and secure the sheets properly to prevent accidents caused by falling objects. 8. First Aid: Keep a first aid kit readily available to address minor injuries. Familiarize yourself with appropriate first aid procedures for cuts, burns, or any other potential injuries that may occur while working with aluminum sheets. By adhering to these safety precautions, you can establish a safe working environment and minimize the risks associated with handling aluminum sheets. Remember to prioritize your safety and the safety of those around you at all times.

- Q:What is the coefficient of expansion for aluminum sheets?

- The coefficient of expansion for aluminum sheets is approximately 0.000022 per degree Celsius. This means that for every degree Celsius increase in temperature, the aluminum sheet will expand by 0.000022 times its original length. This coefficient of expansion is important to consider in applications where the aluminum sheets may be exposed to varying temperatures, as it can affect the overall dimensions and stability of the material.

- Q:How do aluminum sheets perform in terms of dimensional stability?

- Aluminum sheets generally exhibit good dimensional stability due to their low coefficient of thermal expansion, meaning they are less likely to warp or deform when exposed to temperature changes compared to other materials.

- Q:Can the aluminum sheets be used for printing applications?

- Aluminum sheets are indeed suitable for printing applications. Thanks to their smooth and flat surface, aluminum is an excellent choice for printing graphics, images, and text. Various printing methods, including offset printing, screen printing, and digital printing, can be effortlessly employed on these sheets. When opting for aluminum sheets for printing, one can expect durability, resistance against fading and weathering, as well as a polished and sophisticated look. Industries such as advertising, automotive, aerospace, and packaging frequently utilize aluminum sheets for signage, labels, nameplates, and decorative purposes.

- Q:Are aluminum sheets suitable for transportation applications?

- Indeed, aluminum sheets prove to be appropriate for transportation purposes. With its lightweight and robust nature, aluminum emerges as an ideal material for diverse transportation needs. It finds widespread use in the aerospace sector, where it is employed in constructing aircraft structures. Similarly, in the automotive industry, aluminum is extensively utilized for fabricating vehicle bodies, frames, and components. By incorporating aluminum sheets into transportation applications, the overall weight of vehicles can be reduced, thereby enhancing fuel efficiency and increasing payload capacity. Moreover, aluminum's resistance to corrosion ensures its durability and longevity, even in harsh environments. All in all, the attributes of aluminum sheets render them a suitable and optimal choice for transportation applications.

- Q:Are aluminum sheets suitable for wastewater treatment applications?

- Indeed, aluminum sheets prove to be suitable for wastewater treatment applications. With its versatility, aluminum presents several advantages when utilized in wastewater treatment processes. Firstly, aluminum sheets exhibit a high resistance to corrosion, a crucial feature given the harsh and corrosive environment of wastewater treatment plants. This resistance ensures that the aluminum sheets remain intact and unaffected by the chemicals present in the wastewater, thereby preserving their structural integrity. Moreover, aluminum sheets possess exceptional thermal conductivity properties, enabling efficient heat transfer in processes such as wastewater disinfection. This thermal conductivity facilitates the effective elimination of harmful bacteria and contaminants from the wastewater, thereby enhancing the overall treatment process. Furthermore, aluminum sheets are not only lightweight but also durable, making them easy to handle and install in wastewater treatment systems. This characteristic also contributes to their cost-effectiveness, as they require less maintenance and are less susceptible to damage compared to alternative materials. Additionally, aluminum is a sustainable material that can be recycled, thus reducing the environmental impact of wastewater treatment applications. Recycling aluminum sheets aids in the conservation of natural resources and minimizes energy consumption, making it an environmentally friendly choice. In conclusion, aluminum sheets offer a multitude of advantages for wastewater treatment applications. Their corrosion resistance, thermal conductivity, lightweight nature, and recyclability render them a suitable and efficient material for use in wastewater treatment processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Sheet With Hot Rolled With Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords