Aluminium Profile Building Expansion Joints

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminium Profile Building Expansion Joints Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile Building Expansion Joints:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

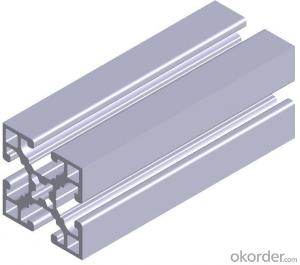

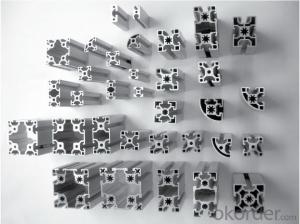

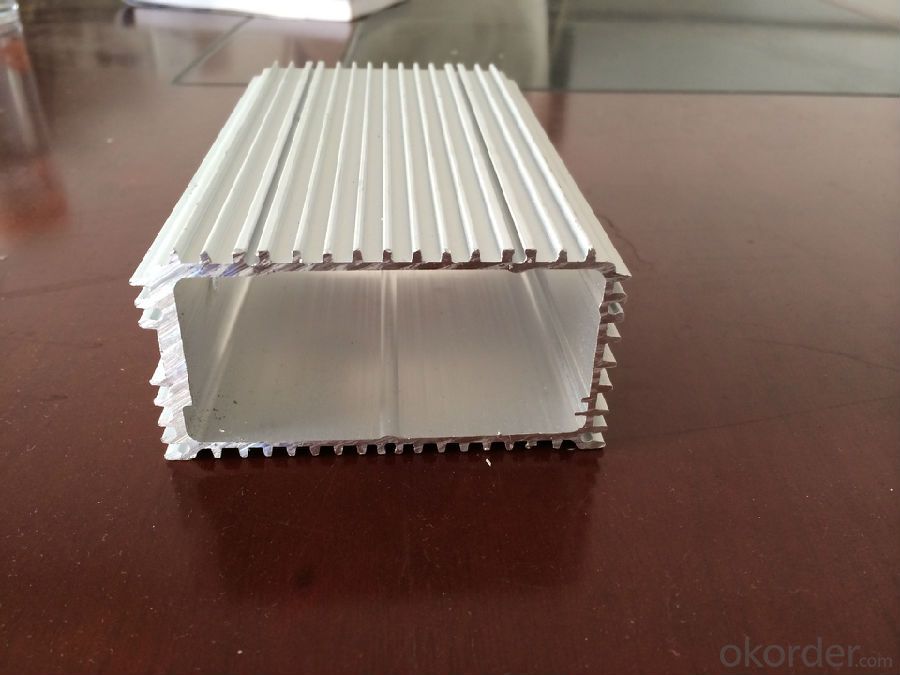

3.Aluminium Profile Building Expansion Joints Images:

4.Aluminium Profile Building Expansion JointsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Can someone please explained what aluminum reacts slowly with dilute acided?Thank you!

- Firstly, dilute acids are weaker than concentrated acids. This slows the rate of reaction. Secondly, Aluminium is less reactive than the Group 1 and Group 2 metals, which slows the rate of reaction. It is less reactive because it has to form 3+ ions which is more draining than forming 1+ or 2+ ions. Thirdly, Aluminium oxidises well in air but, unlike rust, this oxide sticks to the pure aluminium, forming a protective layer.

- Q:Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q:(given the fact that specific gravity of aluminum is 2.7)1. What is its volume?2. The ingot is suspended from a rope and totally immersed in water. What is the tension in the rope (the apparent weight of the ingot in water)?

- first find the volume of your aluminium. youll need this when analyzing the bouant force F(b). the sg of aluminum is 2.7 and the density of water is 1000 kg/m^3 so the density of aluminum is 2.7x1000=2700kg/m^3. the mass is 71N/g = 7.237512742 kg. so volume of our piece of aluminum = mass/density = 0.0026805603 m^3 now analyze the forces being applied to the system. There are three, the force of gravity F(g), the buoyant force F(b) and the tension T. Tension and buoyant force push up, gravity pulls down. the system will be at rest since the rope is holding it at rest. so T + F(b) - F(g) = 0 T + (Volume aluminum X density water X g) - (MAss of aluminum x g) = 0 T + (0.0026805603x1000x9.81) - (71 N (given in problem)) = 0 Solving for T, T = 44.70370346 N = 45 N using sig figs.

- Q:Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Indeed, the utilization of aluminum sheets is appropriate for the production of aircraft fuselages. Aluminum remains a favored selection for aircraft assembly owing to its exceptional strength-to-weight proportion, ability to withstand corrosion, and simplicity in fabricating. Its lightweight nature aids in the reduction of the aircraft's total weight, thereby enhancing fuel efficiency and augmenting payload capacity. Moreover, aluminum exhibits remarkable resilience in enduring the pressures and tensions encountered during flight. Furthermore, it is a readily accessible and economically viable material, rendering it a pragmatic preference for aircraft manufacturers.

- Q:Can aluminum sheets be custom cut to specific sizes?

- Yes, aluminum sheets can be custom cut to specific sizes. Aluminum is a highly versatile material that can easily be cut and shaped to meet specific requirements. With the right tools and equipment, aluminum sheets can be accurately cut to any desired size, whether it's for industrial, commercial, or personal use. This flexibility allows for the customization of aluminum sheets to fit specific applications, making it a popular choice in various industries such as construction, automotive, and aerospace. Whether you need small or large aluminum sheets, they can be easily cut to the exact dimensions you require, ensuring a precise fit for your specific project or application.

- Q:I have a problem when machining aluminium in my machine shop. There are times when the machines aluminium surface turns yellowish (somtimes brown). I do not know what is the main cause of the problem. Is it due to the coolant used?

- Aluminum oxides may appear in different colors depending on hydration states and other variables. Look in a CRC Handbook of Chemistry Physics if available for aluminum compounds and their colors. The colors that you see may also have as much to do with the surface finish as the color of the material on the surface. A microscopically rough surface will appear dark next to a polished surface due to light scattering. I will agree with Ling in principle, but not on details. EDS detection limits on homogeneous samples can be better than 0.1%, although not so good for elements at the light end of the detection range. Current detectors can detect chlorine (a common culprit for aluminum discoloration) at about 0.1%. Your problem with detection and one that Ling has addressed previously may be that a thin film of contamination would not be easily detected by EDS. As Ling suggests, SIMS is a good technique for detecting thin films and low concentrations. The problem with SIMS in this case may be that the detection limits are too good and the technique cannot be quantified. SIMS would detect 2 ppm of chloride and you couldn't tell for sure whether it was 2 ppm, which is probably not an issue here, or 2000 ppm, which would be significant. I would suggest x-ray photoelectron spectroscopy (ESCA or XPS) as an alternative for further study. The technique will analyze thin films (20 A) and detection limits are good enough (about 0.1%). In addition, XPS will give you information about the compounds present, e.g. whether the oxygen is aluminum oxide, aluminum hydroxide, etc. Good Luck.

- Q:What kind of aluminum sheet can be bent with five millimeters?

- Depending on the material, alloy and condition you need, except for the bending performance, the thickness is 5mm, there is no other requirement, and the products that China can meet this requirement are everywhere.

- Q:What are the different surface finishes available for aluminum sheets?

- Aluminum sheets offer a variety of surface finishes, each with its own unique qualities and aesthetic appeal. Some commonly used finishes include: 1. Mill Finish: This is the most basic finish achieved by leaving the aluminum in its as-rolled state, without any further treatment. It has a smooth and shiny appearance, but may have slight imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and offers a wide range of color options. Anodized finishes can be matte or glossy. 3. Brushed Finish: By brushing the aluminum sheet with a fine abrasive material, a textured pattern is created. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes, giving the aluminum a high-end, mirror-like appearance. 5. Embossed Finish: Embossing involves creating raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, adding texture and visual interest to the material. 6. Powder Coated Finish: Powder coating entails applying a dry powder to the aluminum sheet and curing it under heat. This finish provides a durable and weather-resistant coating, available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting various designs or patterns onto the surface of the aluminum sheet. This finish is often used in architectural applications, adding visual interest to the material. These examples demonstrate the range of surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q:Are 101 aluminum sheets resistant to corrosion?

- Indeed, 101 aluminum sheets display remarkable resistance to corrosion. This is attributed to aluminum's inherent ability to form an oxide layer on its surface upon exposure to oxygen, which serves as a formidable shield against corrosion and safeguards the metal from deterioration. Furthermore, the 101 aluminum alloy is meticulously engineered with superior properties that bolster its resistance to corrosion, surpassing other aluminum alloys in this regard. Consequently, when confronted with the need for corrosion resistance, 101 aluminum sheets stand as a dependable option.

- Q:Are aluminum sheets suitable for reflective signage?

- Yes, aluminum sheets are highly suitable for reflective signage due to their excellent reflective properties. The smooth surface of aluminum ensures high visibility and increased reflectivity, making it an ideal material for creating reflective signage that is easily visible, even in low light conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile Building Expansion Joints

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords