Aluminium Prepainted in Coil Form for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Prepainted in Coil Form for Roofing Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Prepainted in Coil Form for Roofing:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

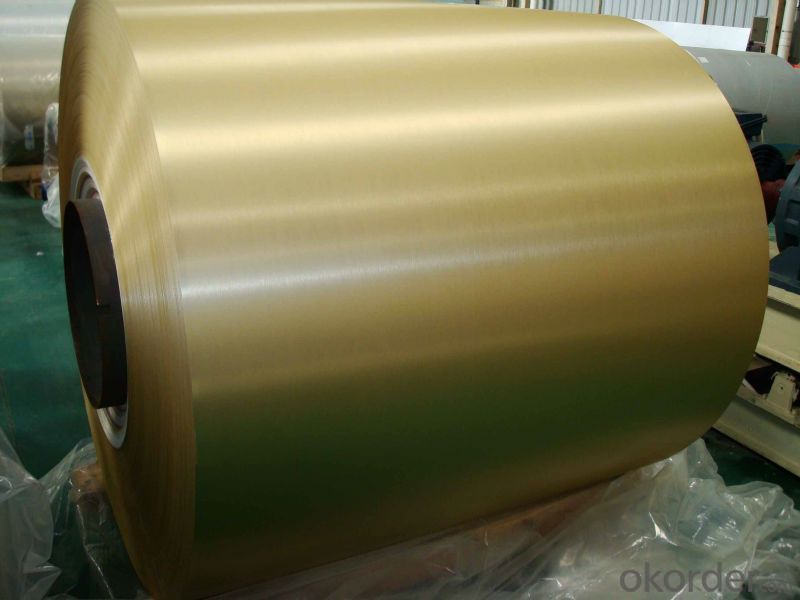

Images of the Aluminium Prepainted in Coil Form for Roofing:

Aluminium Prepainted in Coil Form for Roofing Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepainted in Coil Form for Roofing:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:What are some common applications of aluminum sheets?

- Aluminum sheets have a wide range of applications due to their unique properties. Some common applications of aluminum sheets include: 1. Construction: Aluminum sheets are commonly used in the construction industry for roofing, siding, and window frames. Their lightweight nature and durability make them an ideal choice for these applications. 2. Automotive industry: Aluminum sheets are extensively used in the automotive industry to manufacture car bodies, panels, and components. The lightweight nature of aluminum helps reduce the overall weight of vehicles, leading to improved fuel efficiency. 3. Packaging: Aluminum sheets are commonly used for packaging purposes, especially in the food and beverage industry. They are used to make cans, foils, and lids, thanks to their ability to preserve the freshness and quality of the packaged products. 4. Aerospace industry: Aluminum sheets play a vital role in the aerospace industry. They are used to manufacture aircraft bodies, wings, and structural components due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. 5. Electrical industry: Aluminum sheets are used in the electrical industry for various applications, including manufacturing electrical enclosures, transformers, and bus bars. Aluminum's excellent conductivity and lightweight nature make it a preferred choice for these applications. 6. Marine industry: Aluminum sheets are widely used in the marine industry for building boats, ship hulls, and other marine structures. Aluminum's resistance to corrosion and its ability to withstand harsh marine environments make it a suitable material for these applications. 7. Decorative purposes: Aluminum sheets are frequently used for decorative purposes in architecture and interior design. They can be shaped, engraved, or coated with different finishes to create aesthetically pleasing surfaces for walls, ceilings, furniture, and signage. These are just a few examples of the common applications of aluminum sheets. The versatility, durability, and lightweight nature of aluminum make it a highly sought-after material in various industries.

- Q:What is the weight of the aluminum sheets?

- The weight of the aluminum sheets can vary depending on their size, thickness, and density. To determine the weight, you would need to know the dimensions and density of the specific aluminum sheets in question.

- Q:Are 101 aluminum sheets suitable for agricultural machinery?

- Yes, 101 aluminum sheets are suitable for agricultural machinery. Aluminum is a versatile and lightweight material that offers several benefits for agricultural machinery. It has excellent corrosion resistance, which is crucial for equipment exposed to various weather conditions and chemicals commonly found in the agricultural industry. The strength-to-weight ratio of aluminum is also advantageous, allowing for increased payload capacity and fuel efficiency. Additionally, aluminum is easily formable, enabling manufacturers to create complex shapes and designs for machinery components. Overall, 101 aluminum sheets provide the durability, corrosion resistance, and versatility required for agricultural machinery.

- Q:im making a presentation and once i read through it it feels like its leading up to something but then goes flat. any ideas. my project ' steel cars compared to aluminium'

- Aluminium is extremely flammable. We use it in thermite welding and as solid rocket fuel. The Emperor Napoleon carried* an aluminium fork while the lower royalty had to make do with gold forks. *In those days people carried their table wear around with them same as we carry our car keys.

- Q:Can aluminum sheet be painted or coated after fabrication?

- Yes, aluminum sheet can be painted or coated after fabrication. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance or provide additional protection. The process involves preparing the surface by cleaning and removing any contaminants, followed by applying a primer to improve adhesion. After the primer has dried, a topcoat of paint or coating can be applied to achieve the desired color or finish. The type of paint or coating used will depend on the intended use and the specific requirements of the application. Overall, painting or coating aluminum sheet after fabrication is a common practice and can greatly enhance its aesthetics and durability.

- Q:Are aluminum sheets suitable for cladding?

- Aluminum sheets are indeed appropriate for cladding purposes. The utilization of aluminum as a cladding material is widely favored due to its numerous benefits. Firstly, its lightweight nature facilitates easier handling and installation. This leads to a reduction in the overall weight of the cladding system and a minimization of structural loading. Secondly, aluminum showcases exceptional durability and resistance to corrosion, rendering it suitable for both interior and exterior applications. Additionally, it possesses weather-resistant qualities, ensuring that the cladding remains in optimal condition even in harsh climates. Furthermore, aluminum is an incredibly versatile material that can be effortlessly shaped and fabricated, thus allowing for a diverse range of design options. It may be painted or coated with various finishes to enhance its appearance and provide additional protection. Moreover, aluminum cladding necessitates minimal maintenance, as it does not require frequent cleaning or painting. In summary, aluminum sheets are an exceptional choice for cladding due to their lightweight nature, durability, versatility, and low maintenance requirements.

- Q:What are the colors of iron sheet and aluminum sheet?

- white

- Q:Are aluminum sheets suitable for electrical connectors?

- Indeed, electrical connectors can be effectively made using aluminum sheets. Aluminium, being a metal with high conductivity, is an ideal option for facilitating the flow of electric current. Its low electrical resistance enables the efficient transmission of electricity. Moreover, aluminum is renowned for its lightweight properties, resistance to corrosion, and affordability, rendering it a favored choice for electrical connectors across diverse sectors like automotive, aerospace, and electronics. Nevertheless, it should be emphasized that when aluminum connectors are utilized alongside dissimilar metals, extra precautions might be necessary to avert the occurrence of galvanic corrosion.

- Q:im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q:What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: aluminum alloy checkered plateThe aluminum alloy pattern board is made of the rust proof aluminum alloy and so on. It is made of special pattern, and the patterns are beautiful and elegant. It is not easy to wear and has good antiskid performance. It has strong corrosion resistance and is easy to flush. Different colors can be obtained by surface treatment. The pattern plate is smooth, the cutting size is accurate, easy to install. It is widely used in wall decoration and stairs and stair treads.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Prepainted in Coil Form for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords