Aluminium Checkered Sheet With Good Price In Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Product Description

CNB, INTERNATIONAL CORPORATION'S Aluminum checkered plate is very best-selling in the industrial construction field and decoration field, etc.

There are many different alloy nubmer: 6000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1010,1100, 2024, 3003, 5052,5754,6061,6063,8011, etc.

The temper is include H44, H24, F ,O, H112, H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

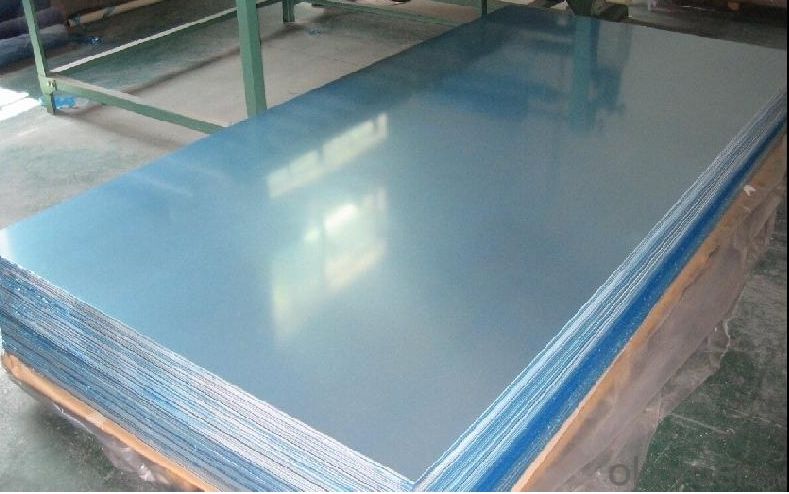

3. Image.

4. Product detailed sizes:

1000mm*2000mm,2000mm*2000mm, 800mm*800mm,etc.500MM*500MM,1000*1000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 400mm to 2500mm, etc.

What is the length range:

---It is from 800mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 12 tons/each size.

How many tons did you export in one year?

---Normally it is around 20000 tons totally.

Where is your client from?

---Normally it is from Pakistan,Saudi Arabia, BANGLADESH,PAKISTAN,FIJI, England,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium plate and alut, aluminum casting coil, etc.

- Q:How do you prevent oxidation of aluminum sheets?

- To avoid oxidation of aluminum sheets, several techniques can be utilized. One commonly used method is to apply a protective coating or finish on the surface of the aluminum sheets. This coating acts as a barrier between the aluminum and the external environment, preventing the metal from reacting with oxygen and forming an oxide layer. There are various types of coatings available for this purpose, such as anodizing, painting, and powder coating. Anodizing involves creating a controlled oxide layer on the aluminum surface through electrolysis. This oxide layer is highly resistant to corrosion and provides excellent protection against oxidation. Painting and powder coating, on the other hand, involve applying a layer of paint or powdered polymer to the aluminum surface. These coatings create a physical barrier that shields the metal from oxygen and moisture. Another effective approach to prevent oxidation is by using aluminum alloys that have enhanced corrosion resistance. These alloys are specifically designed to have a higher resistance to oxidation and can withstand exposure to harsh environments without forming a significant oxide layer. In addition to coatings and alloy selection, proper storage and handling practices play a crucial role in preventing oxidation. It is important to store aluminum sheets in a clean, dry, and well-ventilated area to minimize exposure to moisture and corrosive elements. Contact with acidic or alkaline substances should be avoided, as they can accelerate the oxidation process. Regular cleaning and maintenance of aluminum sheets also help prevent oxidation by removing any contaminants that could promote corrosion. In summary, preventing oxidation of aluminum sheets involves a combination of protective coatings, appropriate alloy selection, and proper storage and handling practices. By implementing these measures, the lifespan and durability of aluminum sheets can be significantly improved.

- Q:Can aluminum sheet be used for soundproofing?

- Yes, aluminum sheet can be used for soundproofing to some extent. Aluminum is a dense and rigid material, making it effective at blocking sound transmission. When used in conjunction with other soundproofing materials, such as foam or mineral wool, it can further enhance soundproofing capabilities. However, it is important to note that aluminum sheet alone may not provide complete soundproofing, as it may still allow some sound to pass through due to its thin nature. Additionally, proper installation and sealing of any gaps or openings is crucial for maximizing the soundproofing effectiveness of aluminum sheet.

- Q:Can aluminum sheets be welded or soldered?

- Aluminum sheets have the capability to undergo both welding and soldering processes, although the techniques for each differ significantly. When welding aluminum, a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process is typically employed, necessitating a high heat source and a filler material to connect the sheets. This process is generally more demanding when compared to welding steel due to aluminum's high thermal conductivity and lower melting point. On the other hand, soldering aluminum involves utilizing a low-temperature solder and flux to bond the sheets together. Usually, specialized solders like aluminum solder or solder with a high tin percentage are employed. Soldering aluminum is typically less prevalent and more intricate than soldering other metals due to the presence of an oxide layer on aluminum, which hinders proper adhesion. To summarize, while both welding and soldering can be utilized for joining aluminum sheets, welding is the more commonly employed method due to its superior strength and durability. Soldering aluminum presents additional challenges due to the requirement for specialized solders and the presence of the oxide layer.

- Q:Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact due to their high strength-to-weight ratio and ability to absorb and distribute energy.

- Q:Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q:Is this aluminium plate ceiling dark keel or bright keel?

- Although as upstairs said, now integrated ceiling are dark fitted keel. Can see your picture, elevation difference also has, should be bright install keel. This requires manufacturers and roof distribution. It is not important to open and install, but the key is where to enter such plates.If you think about the effect, consider getting the information from the scene.

- Q:Are aluminum sheets resistant to impact and vibration?

- Yes, aluminum sheets are generally resistant to impact and vibration due to their inherent strength and flexibility.

- Q:As for graphite and aluminum sheet, which one has a better thermal conductivity?

- aluminum sheet

- Q:Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Yes, aluminum sheets can be used for manufacturing chemical reaction vessels. Aluminum is a versatile material that offers several advantages for this purpose. It is lightweight, durable, and has excellent corrosion resistance, making it suitable for containing various chemicals and reacting with them. Moreover, aluminum is relatively easy to shape and form into the desired vessel design, allowing for flexibility in manufacturing. However, it is important to note that aluminum may not be suitable for all chemical reactions, especially those involving highly corrosive or reactive substances. In such cases, alternative materials that can withstand the specific reaction conditions may be more appropriate.

- Q:Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheets typically require special handling during transportation. This is because aluminum is a lightweight yet fragile material that can easily dent, scratch, or bend. To prevent such damages, it is important to handle aluminum sheets with care, avoiding rough handling, excessive bending, or stacking heavy objects on top. Additionally, protective measures like using padding or wrapping the sheets in protective material can help ensure their safe transportation.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Checkered Sheet With Good Price In Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords