Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

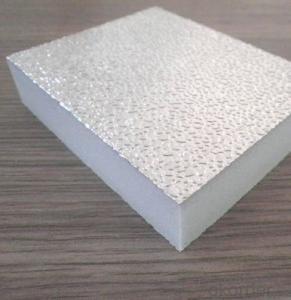

1.Structure of Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

Air ductwork supply is pre-insulated aluminum panels constructed of both aluminum and Poly-isocyanurate. The sandwich panels are comprised of expanded Poly-isocyanurate rigid foam board, faced on both sides by aluminum foil.Ducting is the key part of any central air-conditioning system. It is similar in function to the arteries and veins in the human body as it helps in regulating the temperature in a building. The material used for making ducts for air-conditioning is constantly evolving in order to satisfy the demand for higher thermal efficiency, eco-friendliness, and increased energy savings. Many different materials and systems such as magnetite composite, PVC and so on have been developed as alternatives to the galvanized sheet metal used traditionally. But pre-insulated ducting materials is by far the most popular ducting system in use today. It is essentially a panel made with an insulating material such as PIR (Polyisocyanurate), PUR (Polyurethane) or Phenolic foam material sandwiched in between two layers of aluminium foil. Such a foam panel is easier than traditional galvanized sheet metal to manipulate for complex designs and lighter than its predecessors for installation. These qualities in addition to the fact that it has a much higher thermal efficiency than galvanized sheet metal make it an ideal material for fabricating Airconditioning ducts in harsh climates like the Gulf. Its application has been gradually extended to every type of air distribution system: industrial and commercial.

For construction of air ducting in HVAC systems, the Polyisocyanurate (PIR), PUR (Polyurethane) and/or Phenolic foam panel with 45kg/m3 density, coated with 80/80µm thick embossed aluminum foil have two panel types:

The air ducts fabricated using ALU 80/80 panels can be installed in plants:

with air speed up to 15m/s

with pressure up to 1000Pa

indoor

The air ducts fabricated by using ALU 80/200 panels can be installed in plants:

with air speed up to 35m/s

with pressure 1750Pa

outdoor

2.Main Features of Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel:

Air Duct Panel / Pre-insulated Duct Panel / HVAC Duct Panel :

HVAC Aluminum Foil Duct Board

1. Be used for HVAC Duct system;

2. BS 476 Part 6&7 Class 0.

3. Low thermal conductivity.

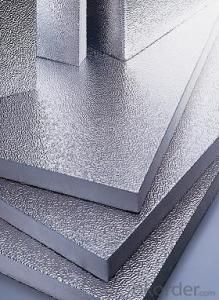

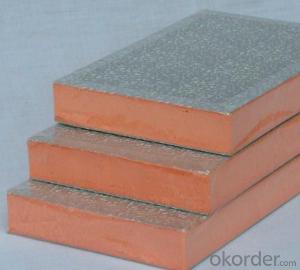

3.Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel Images

Our embossed aluminum sheet/Coil series include:

1.diamond embossed aluminum sheet/Coil

2.orange peel embossed aluminum sheet/Coil

3.stucco embossed aluminum sheet/Coil

4.Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel Specification

Air-conditioning Areas Exposed to weather

Thickness of panels 20 Mm 30 Mm

Thickness of aluminum 80/80 Microns 80/200 Microns

Density of the foam 44-48 Kg/m3 42-48 Kg/m3

Finishing of aluminum Embossed Embossed

Dimension Length: 4meter Width: 1.2meter

Note: Both sides of the aluminum foil are lacquered with a 3g/m2 weatherproof and ultraviolet ray protection polyester lacquer.

Certificate: FORM A, CO ,FORM E ,FORM B ,MTC, SGS and ROHS(client paid for it), MTC

Surface Quality: without any dent, scratches, oiliness , oxidation .

Chemicial composite and Machinary Property: Meet with GB/T, JIS,ENAW, ASTM standard

Month Capacity: 5000MT/month

exporting port: Tianjin, Shanghai

payment: TT or LC at sight

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long for your delivery time?

Commonly 30 working days can be served. If you need the products urgently, we can shorten the delivery time into 20 days.

3. Where the Panels can't be used?

As extractors in the kitchen, as chimneys for smoke or chemical laden smoke

As transportation for solids

Outside temperature range -35ºC and +110ºC

Air speed >15m/s for 20mm thick panel and >35m/s for 30mm thick panel

when the negative or positive pressure inside the duct is: 20mm thick panel >1000Pa and 30mm thick panel >1750Pa

- Q:DISCLAIMER:This question should not in any way what-so-ever be misinterpreted as chatting.

- Teachers who give students worksheets are lazy.

- Q:I need some help with my chemistry homeworkI can't figure out this problemI don't even know where to start; all I know is aluminum oxide is Al2 O3You are an owner of an Aluminum company and you mine Bauxite, an ore of aluminum oxideHow would you obtain pure aluminum metal? Thanks.

- This Site Might Help YouRE: Bohr Model?! Aluminum? For my chem class that I just barely started taking, we're making bohr modelsEven though my teacher explained it, I still dont get the concept of it all, like how the protons are lined up in their inner circle and the outer circlesI get everythign else about atoms except how they're.

- Q:Who has a recipe for garlic mashed red potatoes?

- here it isRoasted Garlic Mashed Potatoes Ingredients: 2 heads garlic, unpeeled Olive oil 2 lbred potatoes, quartered 2 tspsalt, divided 1/4 cup milk 1/4 cup shredded Parmesan cheese 3 Tbsbutter or margarine 1/3 cup chopped fresh parsley 1/2 tsppepper Preptime: 1 hour 30 minutes Yield: 8 servings Preheat oven to 350?Cut off top of garlic, leaving heads intactPlace garlic on a piece of aluminum foil, and drizzle with oilFold foil to sealBake for 1 hour; cool 10 minutesSqueeze pulp from garlic cloves; set asideBring potatoes, 1 tspsalt, and water to cover to a boil in a Dutch oven; boil 15 to 20 minutes or until tenderDrainMash potatoes; stir in garlic, remaining 1 tspsalt, milk, and remaining ingredients until smooth.

- Q:I'm new to bread baking and I have a really great recipe for a crusty French breadIt bakes beautifully and when it comes out of the oven it's really crusty with a soft centerHowever, once it cools down, the crust becomes soft and chewyIs this normal, or should I be doing something else? Do I need to put it back in the oven for a few minutes to reheat it for it to be crusty again? Help!

- Not sure what county you're in but in my city I take my items in a plastic bin or a box, whatever is handy, and then place the items in the appropriate bins marked at the recycling centerUsually you need to sort the items so you might want to have a couple different bins and sort at home to save time.

- Q:where is the thermocouple located and what does it look like on GAFFERS AND SATTLER unit 1967 year, thx for the infoill replace it when i know where it is

- If you want seamless gutters (which are the best way to go) then you want aluminumYour gutter installer will make them on site and hang them with a quicknessIt may not be as expensive as you may think.

- Q:Hey, I recently heard using tinfoil (publix aluminum foil) to cook food in oven with like laying meat on it to bake meat in the ovenIs this true? I've been using it for years :S

- Never stuff the turkeys innardsBasically score the breast with a knife and push some butter into the slitsPlace on a rack in a dish and add 2 cups of waterOn a heat of gas mark 5 cook uncovered in the oven until golden brownThis should take approx 50 mnsRemove from oven and drain the juice from the dish and keepSmear some more butter on the breast, cover loosely with foil, add more water and cook for 25 mns per lb, about 1 hr per k.gHalf an hour before the bird is cooked, remove from oven and drain juice into a containerFlip the turkey on to its breast and cook uncovered for the remaining timeFor stuffing, use mashed potato with parsley and thyme, a few well chopped scallions if available and mix with some of the juice you have retainedPlace in oven and cook at the same time as the turkey(remaining half an hourWhen the turkey is cooked, check that the stuffing has a crust on top, if not give it another 10 mnsOut of the remaining juice, make your gravy.

- Q:If so, at what temperature and for how long?

- YesPlace on a cookie sheet lined with non stick aluminium foil or regular foil that has been coated with a little vegoil or cooking sprayThen use cooking spray to coat the spring rolls, or brush with vegoilBake at 400 degrees for about ten minutes per side, or until golden brown and hot.

- Q:What can I make, thats home made, to smoke out of ???I know you can use foil or an apple, but how do you do that, and what else can I do?

- I am not sure myself when it comes to the technical aspects But, I am interested about your progressI see that you are a very serious contenderPlease keep me updated with your developmentDo youhave a website/blog that show your progress.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminio Puro Gofrado Pre-aislado for Polyisocyanurate (PIR) Rigid Foam Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords