Alloy 6063,6061,6005 or According to Customer’s Choice Aluminium Profile

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

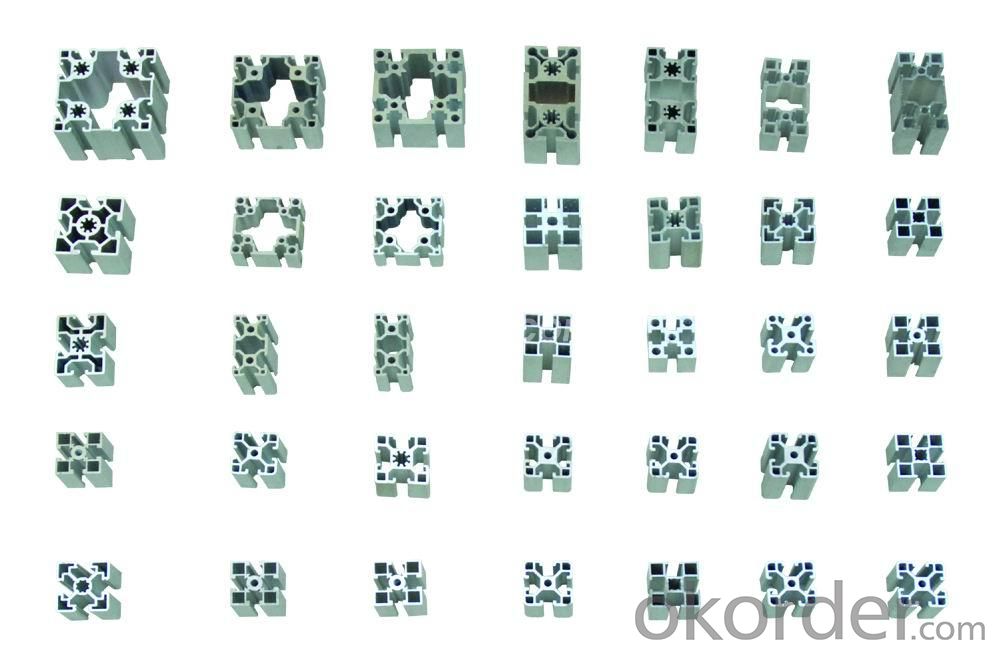

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

- Q:Are there any fire safety considerations when using aluminum profiles?

- Fire safety considerations must be taken into account when utilizing aluminum profiles. Although aluminum is not combustible, it can still contribute to the spread and intensity of a fire. Aluminum profiles, particularly in construction or industrial settings, can act as fuel for a fire and potentially worsen its severity. One crucial consideration is the fire rating of the aluminum profiles. Fire ratings indicate how long a material can withstand fire exposure before failing. It is vital to choose aluminum profiles with appropriate fire ratings that match the specific application requirements. This guarantees that the profiles can delay the fire's spread, providing valuable time for evacuation and firefighting efforts. Another consideration is the use of suitable insulation materials. Aluminum profiles are often used in building facades, curtain walls, and other structural applications. In these cases, it is important to ensure that the insulation materials used with the aluminum profiles are fire-resistant. This prevents the fire from spreading through the building envelope and reduces the risk of structural failure. Furthermore, fire safety measures should be implemented during installation. Proper firestopping techniques should be applied to seal any gaps or penetrations around the aluminum profiles. This prevents flames, smoke, and hot gases from passing from one compartment to another, limiting the fire's spread. Regular maintenance and inspection of the aluminum profiles are also crucial for fire safety. Any damage or deterioration should be promptly addressed to prevent potential fire hazards. Additionally, adequate fire detection and suppression systems should be in place to detect and control fires in a timely manner. Overall, although aluminum profiles themselves are not combustible, it is imperative to consider various fire safety measures when using them in construction or industrial applications. By selecting suitable fire-rated profiles, using fire-resistant insulation materials, employing proper installation techniques, and conducting regular inspections, the risk of fire can be minimized, ensuring the safety of occupants and property.

- Q:What are the different types of surface protection for aluminum profiles?

- There are several types of surface protection for aluminum profiles, including anodizing, powder coating, painting, and laminating. Anodizing involves creating a durable oxide layer on the surface of the aluminum, providing corrosion and wear resistance. Powder coating involves applying a dry powder to the surface and then curing it with heat, creating a tough and decorative finish. Painting involves applying liquid paint to the surface, providing both protection and aesthetic appeal. Laminating involves applying a layer of protective film or sheet to the surface, offering scratch resistance and added durability.

- Q:What are the advantages of using aluminum profiles in the oil and gas industry?

- There are several advantages of using aluminum profiles in the oil and gas industry. Firstly, aluminum profiles offer exceptional strength-to-weight ratio. This means that they provide high structural integrity while being lightweight, which is crucial in industries like oil and gas where equipment needs to be transported and installed in various locations. The lightweight nature of aluminum profiles also reduces the load on structures and equipment, resulting in energy savings and improved efficiency. Secondly, aluminum profiles are highly corrosion-resistant. The oil and gas industry often operates in harsh environments, including exposure to saltwater, chemicals, and extreme temperatures. Aluminum's natural oxide layer acts as a protective barrier, preventing corrosion and ensuring durability in these challenging conditions. This resistance to corrosion significantly reduces maintenance and replacement costs over the lifespan of the equipment. Additionally, aluminum profiles are non-magnetic, making them suitable for applications where magnetic interference is a concern. In the oil and gas industry, where precision and accuracy are crucial, the non-magnetic nature of aluminum profiles ensures that equipment operates without any electromagnetic interference, ensuring data accuracy and reliable performance. Furthermore, aluminum profiles can be easily fabricated and customized to meet specific requirements. They can be extruded into various shapes, sizes, and configurations, allowing for endless design possibilities. This flexibility in manufacturing makes aluminum profiles highly versatile, enabling them to be used in a wide range of applications within the oil and gas industry, including pipe racks, platforms, support structures, and access systems. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, making it a sustainable choice for the oil and gas industry that increasingly focuses on reducing its carbon footprint. Aluminum's recyclability also contributes to cost savings and resource conservation. In summary, the advantages of using aluminum profiles in the oil and gas industry include their high strength-to-weight ratio, corrosion resistance, non-magnetic properties, easy fabrication, and recyclability. These characteristics make aluminum profiles a reliable and cost-effective solution for various applications in this industry.

- Q:Are aluminum profiles suitable for use in the marine industry?

- Yes, aluminum profiles are suitable for use in the marine industry. Aluminum has several properties that make it an excellent material for marine applications. Firstly, aluminum is lightweight yet durable, which is essential for constructing boats and other marine vessels. Its lightweight nature allows for faster speeds and better fuel efficiency. Additionally, aluminum is corrosion-resistant, making it ideal for withstanding the harsh and corrosive marine environment. This property eliminates the need for frequent maintenance and increases the lifespan of marine structures. Furthermore, aluminum has excellent thermal conductivity, which helps dissipate heat quickly, reducing the risk of overheating in marine engines. Lastly, aluminum is highly malleable and can be easily formed into various shapes and profiles, allowing for versatility in design and construction. Overall, the use of aluminum profiles in the marine industry ensures a combination of strength, durability, corrosion resistance, and lightweight properties, making it a suitable choice for marine applications.

- Q:Are aluminum profiles resistant to termites and insects?

- Yes, aluminum profiles are highly resistant to termites and insects. Unlike wood, which is susceptible to termite infestations and insect damage, aluminum is a nonporous material that does not provide a food source for these pests. Additionally, aluminum profiles are typically coated with protective finishes, such as powder coating or anodizing, which further enhance their resistance to termites and insects. This makes aluminum profiles a durable and long-lasting option for various applications, such as window frames, door frames, and other construction projects where termite or insect damage is a concern.

- Q:Can aluminum profiles be used for furniture?

- Yes, aluminum profiles can be used for furniture. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various furniture applications such as tables, chairs, and frames. It offers versatility in design, allowing for sleek and modern aesthetics. Additionally, aluminum profiles can be easily customized and are available in different finishes, making them a popular choice in the furniture industry.

- Q:Are aluminum profiles suitable for use in the telecommunications industry?

- Indeed, the telecommunications industry finds aluminum profiles to be a fitting option. Aluminum, a lightweight and durable material, offers numerous advantages in this field. Firstly, aluminum profiles possess corrosion-resistant qualities, rendering them ideal for outdoor installations like telecommunication towers and antennas which endure harsh weather conditions. This resistance to corrosion ensures the equipment's longevity and reliability. Secondly, aluminum profiles exhibit exceptional thermal conductivity properties, enabling efficient heat dissipation. This attribute holds significant importance in the telecommunications sector, where electronic components generate heat that can impair their performance. By adopting aluminum profiles, cooling systems can be optimized, guaranteeing the equipment's proper functioning. Moreover, aluminum profiles are remarkably versatile, allowing easy customization and fabrication to meet specific requirements. This empowers telecommunications companies to design and construct tailored structures, enclosures, and mounting solutions. Aluminum profiles can be conveniently assembled, disassembled, or modified as needed, offering flexibility in installation and maintenance. Additionally, aluminum profiles provide electromagnetic shielding properties, playing a crucial role in minimizing interference between different communication systems. This shielding helps maintain the quality and reliability of transmitted signals. Furthermore, aluminum stands as a sustainable material, being 100% recyclable and possessing a low carbon footprint compared to other metals. This renders it an environmentally friendly choice for the telecommunications industry, aligning with the increasing emphasis on sustainability and reducing environmental impact. In conclusion, due to their corrosion resistance, thermal conductivity, versatility, electromagnetic shielding properties, and sustainability, aluminum profiles prove to be highly suitable for implementation in the telecommunications industry. These qualities establish aluminum profiles as a dependable and efficient choice for various applications in telecommunications infrastructure.

- Q:Where is the aluminum profile market in Tianjin?

- Industrial aluminium profile standard profile:1530156015901640, 2020204020803030, 30R arc, 3030W 3030, 3030R, 3030RQ, 3060309030150, 4040A, 4040Q, 4040L4040W, 4040Z, 40R arc, 40 right angle, 4060Q, 4060L, 4060Z, 4080, 4080L, 4080W, 8080, 8080W, 606080120100100, 1201204012045454545L 4545Q 4545W 45909090 9090W 45R 4560 4560W 501005050501006060 6060L arc 4545RQ (1530-120120 Series) line industrial profiles and accessories can be assembled into processing products: tool rack (car), operation table, special tool cart, line table, product display, LCD panel, sun room, display cabinets, display rack, mechanical seal cover, shelves, product testing equipment, non-standard equipment, industrial fence, plotter, testing equipment, laboratory equipment, biological machine, labeling machine, production line, motor rotor bracket, electronic products production line, production line, line table, equipment protection barrier, LCD panel production equipment

- Q:Can aluminum profiles be used for modular shelving systems?

- Yes, aluminum profiles can be effectively used for modular shelving systems. Aluminum is a lightweight yet strong material that offers excellent durability and resistance to corrosion. Its versatility makes it suitable for various applications, including shelving systems. Aluminum profiles can be easily customized and adapted to create modular shelving units of different sizes and configurations. Additionally, aluminum profiles can be easily assembled and disassembled, making them ideal for modular systems that can be adjusted or expanded as needed. Overall, aluminum profiles provide a reliable and aesthetically pleasing solution for modular shelving systems.

- Q:What kind of equipment are needed for the production of aluminum profiles?

- The production of aluminum equipment not hundreds of several decades, from the beginning, homogeneous casting furnace, extrusion machine, anodic electrophoretic coating production line groove, powder powder production line, fluorocarbon paint production line, insulated aluminum production line, processing workshop welding riveting, stitching and other processing equipment. Plus to die do I still have, cars, milling, grinding, drilling, EDM, wire cutting, and other processing equipment. I am now in a small department work of aluminum processing company.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy 6063,6061,6005 or According to Customer’s Choice Aluminium Profile

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords