Aerosol Can for Hair Spray,Φ57mm Tinplate Material, HIgh Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief description

Content: hair spray

Size: 57X260mm

Printing: CMYK printing as Per Customer Design

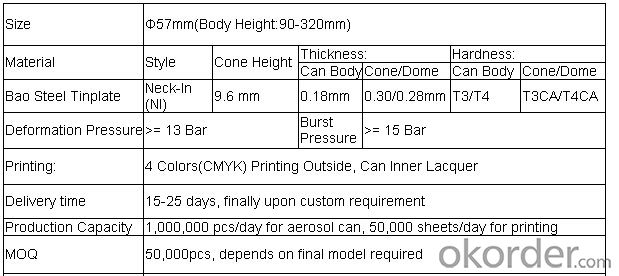

2.Detailed Specification

3.Usage:

suitable for insecticide, air freshener, body spray, lighter refill, car care etc

4.Packing

5.Appearance Specifications

Diameter(mm) | Type | Straight(mm) |

45mm | Necked-in | 80-220 |

52mm | Necked-in | 80-300 |

52mm | Straight | 76-200 |

57mm | Necked-in | 90-240 |

60mm | Necked-in | 90-240 |

60mm | Straight | 80-300 |

65mm | Necked-in | 80-240 |

65mm | Straight | 80-240 |

6.FAQ

1. Delivery Time:15-25 days, time can be shorten upon customer’s situation

2. Productivity:1,000,000 Cans/Day; 500,000 Printing Sheets/Day

3. MOQ:50,000pcs, but finally upon your size

4. Payment Term: 30% TT in advance, 70% balance against BL copy; 100% by LC at sight

- Q:What are the different types of tinplate finishes?

- There are several different types of tinplate finishes, including bright finish, stone finish, matte finish, and lacquered finish.

- Q:How is tinplate used in the pharmaceutical industry?

- Tinplate is commonly used in the pharmaceutical industry for packaging purposes. It is often used to make containers, such as cans or tubes, for storing and protecting medicines, ointments, creams, or other pharmaceutical products. Tinplate containers provide a durable and protective barrier against external elements, ensuring the integrity and safety of the medication. Additionally, tinplate's resistance to corrosion makes it a suitable choice for pharmaceutical packaging, as it helps to maintain the quality and efficacy of the products over an extended period.

- Q:The composition of tinplate?

- There are other statements, such as China used this lamp tin plate made of kerosene, shaped like a horse, so called "tin".

- Q:Can tinplate be painted or printed on?

- Yes, tinplate can be painted or printed on.

- Q:How does tinplate contribute to the protection of pharmaceutical products?

- Tinplate contributes to the protection of pharmaceutical products by providing a secure and durable packaging solution. Its corrosion-resistant properties help prevent contamination and maintain the integrity of the products, ensuring their safety and effectiveness. Additionally, tinplate's opaque nature protects the pharmaceuticals from light exposure, which can degrade certain formulations.

- Q:What are the advantages of using tinplate for stationery?

- One advantage of using tinplate for stationery is its durability. Tinplate is known for its strength and resistance to corrosion, making it highly durable and long-lasting. This ensures that stationery items made from tinplate, such as pencil cases or storage tins, can withstand regular use and maintain their functionality over time. Additionally, tinplate is also a versatile material that can be easily shaped and molded into various designs, allowing for creative and aesthetically pleasing stationery products.

- Q:What are the main trends in tinplate packaging?

- Some of the main trends in tinplate packaging include the increasing demand for sustainable and eco-friendly packaging solutions, the rise of convenient and innovative packaging designs, and the incorporation of advanced technologies for improved product protection and preservation. Additionally, there is a growing preference for personalized and customized tinplate packaging to enhance brand identity and consumer engagement.

- Q:What are the main challenges in tinplate warehousing?

- One of the main challenges in tinplate warehousing is the fragile nature of the product. Tinplate is susceptible to scratching, denting, and corrosion, so careful handling and storage procedures are necessary to prevent damage. Additionally, due to its relatively low melting point, tinplate requires proper temperature and humidity control to avoid deformation or discoloration. Lastly, tinplate is often packaged in large and heavy rolls, making logistics and space utilization critical challenges in warehousing operations.

- Q:What are the typical manufacturing processes for tinplate products?

- The typical manufacturing processes for tinplate products include coil cutting, cleaning and coating, pressing or stamping, forming or shaping, welding or soldering, and final finishing or packaging.

- Q:Can tinplate be used for packaging baby food and formula?

- Yes, tinplate can be used for packaging baby food and formula. Tinplate is a type of steel coated with a thin layer of tin, making it corrosion-resistant and suitable for food packaging. Its durability and protective properties make it an ideal choice for maintaining the quality and safety of baby food and formula.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aerosol Can for Hair Spray,Φ57mm Tinplate Material, HIgh Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60000 PCS

- Supply Capability:

- 300000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords