AA3xxx Hot Rolled Aluminum Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of AA3xxx Hot Rolled Aluminum Coils Used for Construction Description

AA3xxx Hot Rolled Aluminum Coils Used for Construction is cut from aluminum coils 3xxx. AA3xxx Hot Rolled Aluminum Coils Used for Construction is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA3xxx Hot Rolled Aluminum Coils Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA3xxx Hot Rolled Aluminum Coils Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

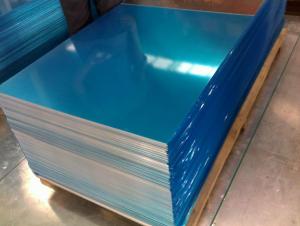

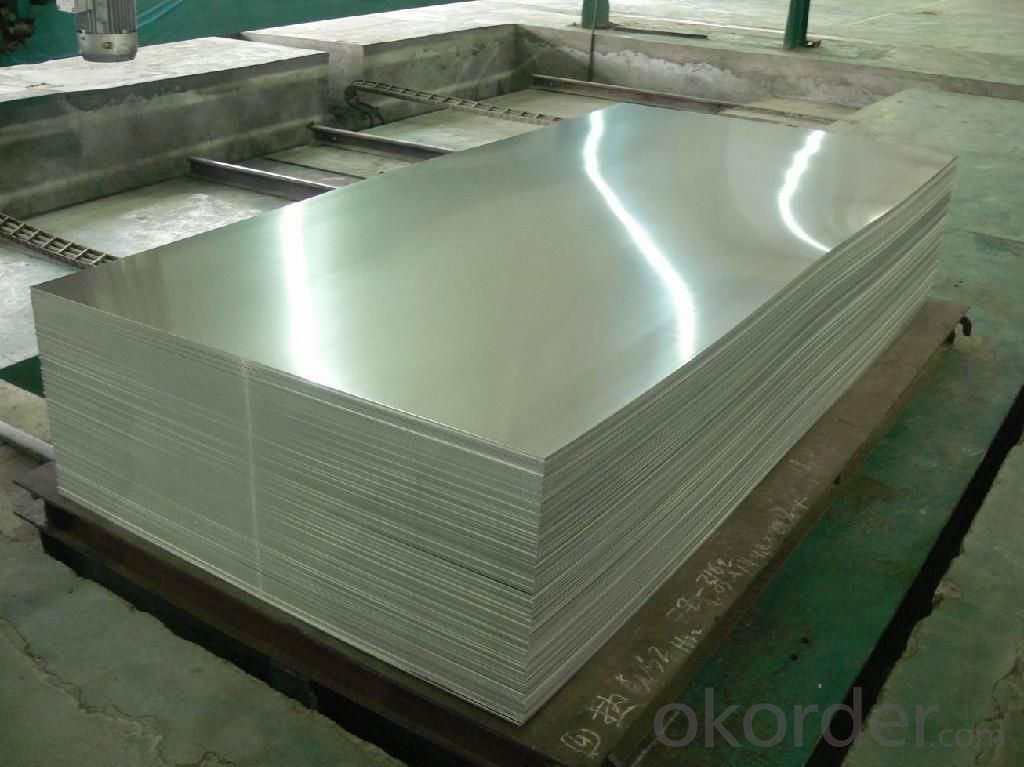

3.AA3xxx Hot Rolled Aluminum Coils Used for Construction Images

4.AA3xxx Hot Rolled Aluminum Coils Used for Construction Specification

Alloy | AA3xxx (AA3105 etc.) |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA3xxx Hot Rolled Aluminum Coils Used for Construction

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:Can aluminum sheets be used for HVAC systems?

- Yes, aluminum sheets can be used for HVAC systems. Aluminum is a popular choice for HVAC applications due to its excellent corrosion resistance, lightweight properties, and thermal conductivity. It is commonly used for manufacturing air conditioner coils, heat exchangers, ductwork, and other components in HVAC systems.

- Q:Is aluminum sheet resistant to UV rays?

- Indeed, aluminum sheet exhibits resistance to UV rays. By nature, aluminum develops a safeguarding oxide layer which functions as a shield against UV radiation. This protective layer aids in safeguarding the aluminum sheet from harm or deterioration caused by the sun's UV rays. Consequently, aluminum sheet proves to be an appropriate material for outdoor usage, enduring extended exposure to sunlight without experiencing fading or deterioration. Moreover, the reflective characteristics of aluminum also contribute to its resistance against UV rays, as it can effectively reflect a considerable portion of the sun's rays, diminishing heat absorption and the likelihood of damage.

- Q:Are aluminum sheets suitable for use in food processing or storage?

- Aluminum sheets are highly suitable for use in food processing or storage. This metal is non-toxic, resistant to corrosion, and possesses exceptional thermal conductivity. These characteristics make it an ideal material for various food applications. Aluminum sheets are commonly utilized in the production of food and beverage cans, foil wraps, trays, and containers. In terms of food preservation, aluminum is impermeable to oxygen, light, moisture, and microorganisms. This quality ensures that the quality and freshness of food products are safeguarded. Additionally, it prevents the transfer of flavors, odors, and contaminants. Moreover, aluminum's lightweight and manageable nature make it convenient for packaging and transporting food items. Furthermore, aluminum sheets are hygienic and easy to clean, which is crucial in food processing and storage settings where cleanliness is of utmost importance. They can be easily sterilized and do not retain any bacteria or food particles that may lead to contamination. In conclusion, aluminum sheets are an excellent choice for food processing and storage due to their non-toxic nature, resistance to corrosion, excellent thermal conductivity, impermeability to oxygen and moisture, ability to preserve food quality, and hygienic properties.

- Q:Can aluminum sheet be used for automotive body panels?

- Automotive body panels can indeed utilize aluminum sheets. In fact, aluminum is gaining popularity in the automotive industry due to its numerous advantages. Firstly, aluminum surpasses steel in terms of weight, leading to improved fuel efficiency and overall vehicle performance. Furthermore, aluminum boasts high resistance to corrosion, providing durability for body panels exposed to the elements. Additionally, aluminum exhibits remarkable formability, enabling the creation of intricate designs and enhancing design flexibility during vehicle production. Moreover, aluminum excels in absorbing crash impact, thereby enhancing vehicle safety. Nevertheless, it is important to acknowledge that utilizing aluminum for automotive body panels may necessitate specialized equipment and techniques for welding and repair purposes.

- Q:My aluminum storm windows are wasting energy in my home, however, the $7000 estimate to replace them is beyond (well beyond) my comfort zone.I know aluminum is a great conductor of hot and cold. I was considering cleaning the frames, and then coating them with a brush on clear or possibly white liquid rubber to reduce the conductivity. Any idea as to how much benefit I'll realize? Is flammability going to be an issue?I need some solid answers please. Trolls go get your two points elsewhere.Thanks.Your help is much appreciated.

- There are rubberized automotive undercarriage coatings that are designed to adhere to all metals, including aluminum. That would solve the problem of finding something that can stick to the frames, but I honestly don't know if it would help with the heating issue. I also believe they only come in black, I'm not sure if there's a white but it could be painted, Chassis Saver by Magnet is one I believe, the other is a Por 15 product. I'd like to know if it works though, I've got similar problems in my house.

- Q:Are aluminum sheets easy to clean?

- Yes, aluminum sheets are generally easy to clean. Aluminum is a non-porous material, which means that it does not absorb liquids or stains easily. This makes it relatively easy to wipe off dirt, dust, or spills from the surface of aluminum sheets using a damp cloth or sponge. Additionally, aluminum is resistant to rust and corrosion, so it does not require any special cleaning agents or treatments. However, it is important to note that abrasive cleaners or scrubbing pads should be avoided as they can scratch the surface of the aluminum. Overall, with regular maintenance and proper cleaning techniques, aluminum sheets can be kept clean and in good condition for a long time.

- Q:What is the specific heat capacity of aluminum sheets?

- The approximate specific heat capacity for aluminum sheets is 0.897 J/g°C, indicating that to increase the temperature of 1 gram of aluminum by 1 degree Celsius, 0.897 joules of energy is needed. While the specific heat capacity may slightly differ based on the aluminum sheet's purity and specific alloy, this value serves as a fairly accurate approximation for the majority of commonly used aluminum sheets.

- Q:Are the aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. Aluminum is a versatile material that can be easily shaped, cut, and manipulated to create various decorative elements. It is lightweight, durable, and resistant to corrosion, making it a popular choice for both indoor and outdoor applications. Aluminum sheets are available in a wide range of finishes, colors, and patterns, allowing for endless design possibilities. Whether it's for architectural accents, signage, furniture, or artwork, aluminum sheets can be used to enhance the aesthetic appeal of any space.

- Q:Can aluminum sheets be anodized with custom colors?

- Custom colors can indeed be applied to aluminum sheets through the process of anodizing. Anodizing involves the application of an electrochemical procedure that adds a protective oxide layer to the aluminum's surface, thereby enhancing its durability and resistance to corrosion. In this process, the aluminum sheet is submerged in an electrolytic solution while an electrical current is passed through it. This induces a controlled oxidation of the aluminum's surface, leading to the formation of a porous layer that can be colored with dyes to achieve desired shades and hues. By carefully selecting the appropriate dye, a wide array of custom color options can be achieved. Moreover, anodized aluminum sheets offer versatility as they can undergo additional treatments like laser engraving or printing to create distinctive designs and patterns. Therefore, they are highly suitable for a diverse range of applications in industries such as architecture, automotive, and electronics.

- Q:Can aluminum sheets be used for fencing?

- Yes, aluminum sheets can be used for fencing. Aluminum is a lightweight and durable material, making it suitable for fencing purposes. It is resistant to rust and corrosion, making it a long-lasting option. Additionally, aluminum sheets offer a sleek and modern look to any fence.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AA3xxx Hot Rolled Aluminum Coils Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords