304L 304 316 Stainless Steel Bar for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product name: 316 stainless steel round polished bar

Name | 316 stainless steel round polished bar |

Standard | AISI, ASTM, JIS,GB,EN,DIN |

Grade | 201/304/316/304L/316L |

Technology | Hot Drawn and Cold Drawn |

Form | Round/Square/Hexagonal Bar |

Diameter | 0.3 mm – 100mm |

| Length | Customized |

The sizes or thickness of stainless steel Bar can be customized. Our customer service staffs are available 7/24. | |

Chemical Composition (%)< stainless steel bar >

Type | C | Si | Mn | P | S | Ni | Cr | Mo |

201 | ≤0.15 | ≤0.75 | 5.5-7.5 | ≤0.06 | ≤0.03 | 3.5-5.5 | 13.5-15.0 | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | ≤0.06 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | |

304 | ≤0.08 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 18.0-20.0 | |

304L | ≤0.03 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 8.0~11.0 | 18.0-20.0 | |

316 | ≤0.08 | ≤1.00 | ≤2 | ≤0.035 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.0-3.0 |

316L | ≤0.03 | ≤0.75 | ≤2 | ≤0.045 | ≤0.030 | 10.0~14.0 | 16.0~18.5 | 2.0-3.0 |

Advantages of 316 stainless steel round polished bar

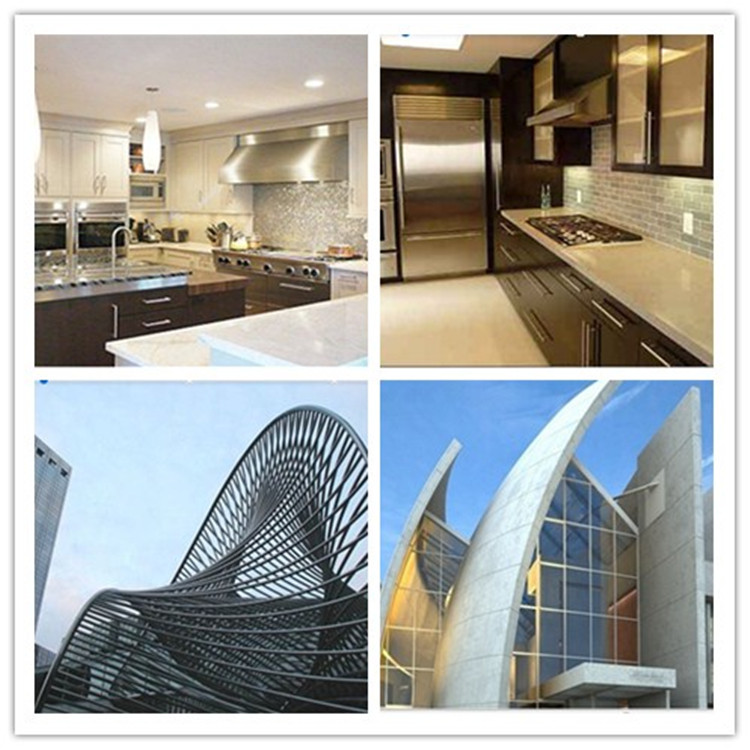

A : Elegance Surface and Diversity Usage

B : Corrosion Resistance and Longer Srevice Life

C :Heat Resistance

D: High Strength

F :High Strength of Oxidation Resistance

G: High Plasticity

H: Easy Surface Treatment

I : Hygiene and High Degree of Finish

J: Excellent Welding Performance

Our experience in developing and pioneering specialized stainless steel fabrications for our customers has made us solidly proficient at prototyping and design.

Because we specialize in multiple industries and reap manufacturing expertise,

we will be able to make your custom parts in the most cost-efficient manner.

Additionally, we have launched our own product line.

We are always open to new challenges and we are constantly working to increase our stainless steel fabricating skills and thereby reduce your costs as well as ours.

Stainless steel manufacturing is an art and a science;

it's a science because we relentlessly seek efficiency

It's an art because we expect and respect your particular needs.

Call us!

We want for your inquiry.

Technological Process of 316 stainless steel round polished bar

Quality Speaks Volumes

Boro has developed and produced premium stainless steel fabrications for over five hundred manufacturing, military, and general industrial companies.

We've run thousands of jobs and thousands of part designs.

We have outstanding deliverability and are ISO BV SGS registered .

So you know you're getting a quality product.

Our experience with reducing costs for our customers through long-run jobs is proven and reliable.

With many long term customers, our stainless steel fabrication services

are low cost and high quality in this present world marketplace.

Boro pursues improvement in every department. Roughly one tenth of company revenue is spent on new technology, renovations, improvements, & strategic market preparation.

Our entire business model (prospect to job close) has been completely value streamed and most of our workflow is strictly managed & controlled.

We maintain records and backups of all pertinent job data.

Company Information

China National Building Materials Group Corporation (CNBM) was established in 1984 with approval of the State Council, and then became a Central Enterprise under direct supervision of State-owned Assets Supervision and Administration Commission of the State Council in 2003. It is in charge of the administrative affairs in China building materials industry. By the end of 2013, CNBM’s total assets exceeded RMB 360 billion, with over 130,000 employees, and 20 companies under direct management with 100% share control or majority control, among which 6 were listed companies, including 2 oversea listed. On July 7th, 2014, CNBM with revenue USD 41028 million, was ranked 267th on the ”World Top 500 Enterprises” by Fortune Magazine.

PACK & DELIVERY

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

Application

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:How many kinds of stainless steel bars?

- According to the material quality, there are 4 kinds of austenitic stainless steel bars, ferritic stainless steel bars, martensitic stainless steel bars and duplex stainless steel bars

- Q:Can stainless steel bars be used in the pulp and paper aftermarket?

- Yes, stainless steel bars can be used in the pulp and paper aftermarket. Stainless steel is highly resistant to corrosion and can withstand harsh chemical environments, making it an ideal material for use in the pulp and paper industry. It offers excellent strength and durability, ensuring long-lasting performance in various applications such as paper machines, digesters, and chemical recovery systems.

- Q:Can stainless steel bars be coated with a protective film?

- Yes, stainless steel bars can be coated with a protective film to enhance their durability and resistance to corrosion.

- Q:What is the difference between brushed and satin stainless steel bars?

- Brushed and satin stainless steel bars are commonly utilized finishes for stainless steel surfaces, yet they possess distinct differences. Brushed stainless steel bars exhibit a distinctive textured appearance achieved through the use of a wire brush or abrasive pad. This technique results in parallel lines or grooves on the surface, providing it with a unique look. Furthermore, the brushing technique aids in concealing scratches or imperfections that may develop over time, making brushed stainless steel bars a popular choice for areas with high foot traffic or applications that prioritize appearance. In contrast, satin stainless steel bars possess a smoother and more uniform finish when compared to brushed stainless steel bars. The satin finish is attained by employing a combination of sanding and polishing techniques, resulting in a less reflective and glossy surface. Satin stainless steel bars are renowned for their elegant and sophisticated appearance, making them a sought-after option for contemporary and modern designs. Regarding maintenance, both brushed and satin stainless steel bars are relatively easy to clean and maintain. However, due to the textured nature of brushed stainless steel, it may necessitate more frequent cleaning to eliminate accumulated dirt or grime within the grooves. Conversely, satin stainless steel bars are generally more resistant to visible smudges and fingerprints. Ultimately, the selection between brushed and satin stainless steel bars depends on personal preference and the desired aesthetic. Both finishes offer their own distinctive appearance and can be effectively employed in various applications, thus it is crucial to consider the overall design and style of the space prior to making a decision.

- Q:Can stainless steel bars be used in the agricultural industry?

- Certainly, the agricultural industry can make use of stainless steel bars. Stainless steel, being a versatile and resilient material, brings numerous advantages to agricultural applications. It possesses corrosion resistance, making it especially valuable in environments that have high levels of moisture or are exposed to chemicals and fertilizers. Stainless steel bars have the potential to be employed in a diverse range of agricultural equipment, machinery, and infrastructure, including barns, animal enclosures, gates, fences, and irrigation systems. Furthermore, stainless steel bars are easily maintained, cleaned, and sanitized, rendering them highly suitable for use in food processing and storage facilities within the agricultural sector.

- Q:Can stainless steel bars be used in water treatment applications?

- Indeed, water treatment applications can utilize stainless steel bars. Owing to its exceptional resistance to corrosion and rust, stainless steel proves to be a perfect fit for environments encompassing water and chemicals. In the realm of water treatment, it finds widespread application in processes like filtration, disinfection, and purification. Water treatment systems can employ stainless steel bars to fabricate an array of components, encompassing screens, tanks, pipes, and pumps. Its enduring nature and resistance to corrosion guarantee an extended lifespan and minimal maintenance needs, establishing it as a trustworthy option for water treatment applications.

- Q:Which is good, the moxibustion bar, the stainless steel and the brass?

- Whether it is a cylindrical stainless steel or brass contain metal and other materials made, the cylinder bottom pointed flat sleeve, a small tube, a small tube around the hole. Is a kind of warming moxibustion model is applied to provide gas ball Everfount moxa burning will be the formation of oxygen, and air pressure drug to the lesion sites, deep red point through, can be directly carried out on the drug gas heat control, and add the medicine bowl, convenient treatment according to the illness need medication, plus ginger and garlic medicine, cake, enhance the treatment effect, adding poly gas anti burn cover, make the medicine gas in the lesion site, stay together to improve the curative effect, acupuncture, to prevent burns when stopping foreign aggression, moxibustion, burning fire tube automatically extinguished.

- Q:What is the difference between stainless steel bars and rods?

- Stainless steel bars and rods find common usage in various industries and applications, yet there exist notable distinctions between the two. To begin with, their shapes differ significantly. Stainless steel bars possess a rectangular or square cross-section and tend to be longer, while stainless steel rods have a circular cross-section and are generally shorter. This divergence in shape renders bars more appropriate for structural applications, providing support and stability, while rods are commonly employed for specialized purposes in machinery or equipment. Another disparity lies in their manufacturing processes. Stainless steel bars typically undergo hot rolling or cold drawing, resulting in a smooth and polished surface finish. Conversely, stainless steel rods are often manufactured using techniques like extrusion or centerless grinding, leading to a more precise and uniform diameter. Regarding strength and durability, both stainless steel bars and rods showcase high resistance to corrosion, making them ideal for usage in harsh environments or areas with frequent moisture exposure. However, due to their distinct shapes, bars generally possess a higher load-bearing capacity compared to rods. Cost serves as another differentiating factor between bars and rods. Stainless steel bars are usually pricier than rods due to the additional processing involved in their production. The longer length and larger cross-section of bars also contribute to their elevated cost. In conclusion, while both stainless steel bars and rods share excellent corrosion resistance properties, their dissimilarities in shape, manufacturing process, strength, and cost make them suitable for separate applications. Bars are commonly utilized for structural purposes, while rods find frequent use in machinery and specialized equipment.

- Q:Are stainless steel bars resistant to chemical corrosion?

- Yes, stainless steel bars are generally resistant to chemical corrosion. Stainless steel is an alloy made primarily of iron, chromium, and other elements such as nickel and molybdenum. The high chromium content in stainless steel forms a protective layer on the surface, called a passive film, which prevents the metal from reacting with the surrounding environment. This passive film acts as a barrier against chemical corrosion, making stainless steel bars highly resistant to many corrosive substances such as acids, alkalis, and chlorides. However, it is important to note that the resistance to chemical corrosion may vary depending on the specific grade and composition of the stainless steel used. In extreme conditions or exposure to highly aggressive chemicals, certain grades of stainless steel may still experience some level of corrosion. Therefore, it is essential to select the appropriate grade of stainless steel based on the specific chemical environment in which the bars will be used.

- Q:What are the different types of stainless steel bar shapes for architectural purposes?

- Some common types of stainless steel bar shapes used for architectural purposes include round bars, square bars, flat bars, and hexagonal bars. These shapes offer different aesthetic and structural possibilities in architectural designs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304L 304 316 Stainless Steel Bar for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords