Stainless Steel Pipe Manufacturers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

stainless steel pipe manufacturers

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 59, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.24-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe) |

Chemical Composition | |||||||

Material | C | Si | Mn | P | S | Cr | Ni |

201 | ≤0.12 | ≤0.75 | 9.5-12.5 | ≤0.045 | ≤0.03 | 13-16 | 0.8-1.5 |

304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18-19 | 8-10 |

316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.035 | ≤0.03 | 10-14 | 16.0-18.5 |

430 | ≤0.12 | ≤0.75 | ≤2.0 | ≤0.04 | ≤0.03 | 16-18 | ≤0.6 |

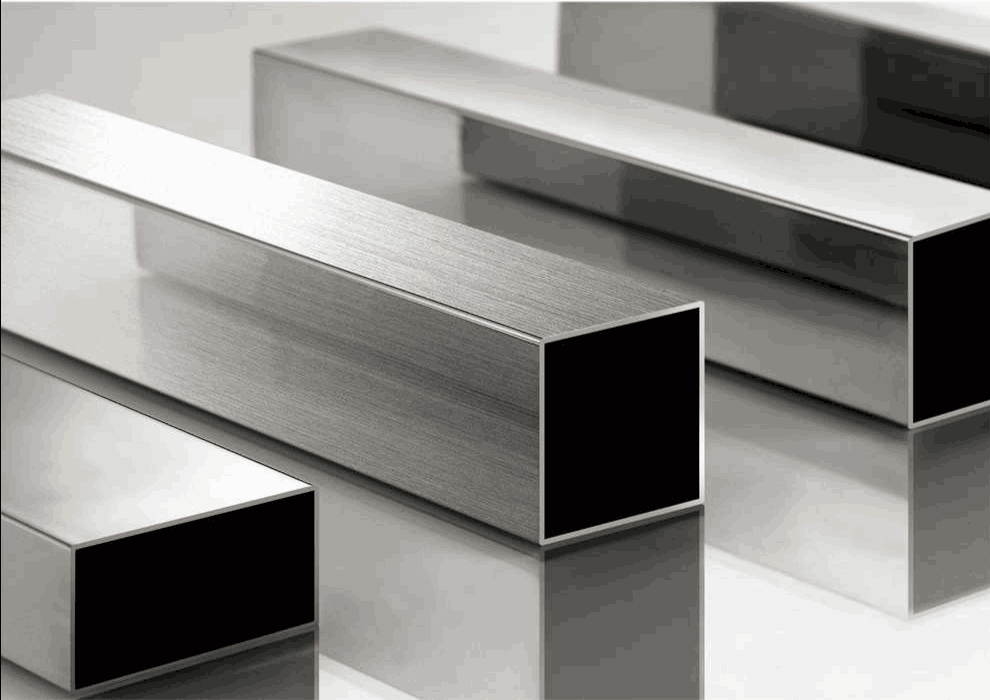

Square pipe and rectangle pipe

round pipe

PACK & DELIVERY

Packaging & Delivery of stainless steel pipe manufacturers

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

COMPANY INFORMATION

Company Information

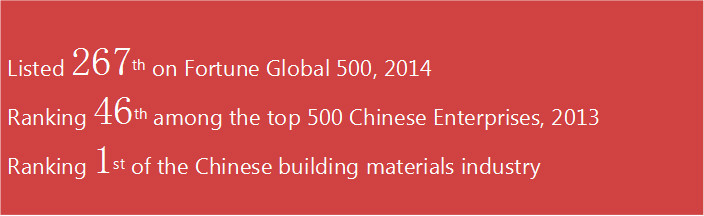

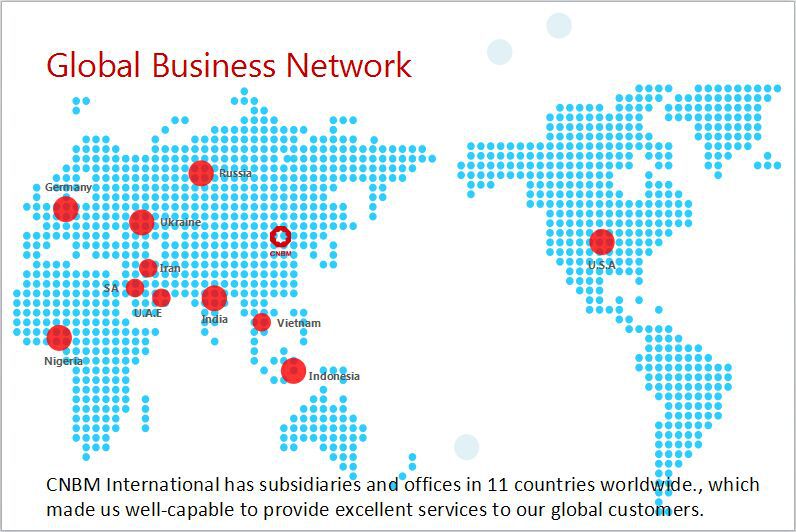

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Client

Export Markets Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories

- Q:How do stainless steel bars resist sulfuric acid?

- Stainless steel bars possess exceptional resistance against various corrosive substances, such as sulfuric acid. This resistance can be attributed to the unique composition of stainless steel, which contains at least 10.5% chromium. The presence of chromium in stainless steel results in the formation of a protective layer called a passive film on its surface. When stainless steel bars come into contact with sulfuric acid, the passive film acts as a barrier, preventing direct attack on the underlying metal by the acid. This film is capable of self-healing, meaning that if it gets damaged or removed, it can quickly reform when exposed to oxygen. Consequently, stainless steel bars can maintain their corrosion resistance even in the presence of sulfuric acid. Moreover, the high chromium content in stainless steel provides additional protection against sulfuric acid. Chromium has an inherent ability to react with oxygen in the atmosphere, leading to the formation of a thin, invisible oxide layer on the surface of stainless steel. This oxide layer further strengthens the resistance of stainless steel bars against sulfuric acid, acting as an additional barrier between the acid and the metal. In conclusion, the combination of the passive film and the oxide layer formed by chromium enables stainless steel bars to endure the corrosive effects of sulfuric acid. As a result, they are a durable and dependable option for applications that require resistance against this acid.

- Q:What are the common sizes of stainless steel bars?

- Common sizes of stainless steel bars can vary depending on the specific application and industry requirements. However, some of the most common sizes of stainless steel bars include diameters ranging from 1/8 inch (3.175 mm) to 12 inches (304.8 mm). The lengths of stainless steel bars can also vary but commonly range from 10 feet (3.048 meters) to 20 feet (6.096 meters). Additionally, stainless steel bars are available in various shapes such as round, square, hexagonal, and flat, with each shape having its own set of standard sizes. It is important to note that these sizes are just a general representation and specific sizes may be available based on the manufacturer and distributor.

- Q:Can stainless steel bars be used in the transportation aftermarket?

- Yes, stainless steel bars can be used in the transportation aftermarket. Stainless steel is a versatile and durable material that offers excellent corrosion resistance, making it an ideal choice for applications in the transportation industry. Stainless steel bars can be used in various aftermarket components such as truck accessories, trailer parts, railings, and brackets, among others. They provide strength and stability while withstanding harsh environmental conditions, including exposure to moisture, chemicals, and extreme temperatures. Additionally, stainless steel bars offer aesthetic appeal and require minimal maintenance, making them a cost-effective solution for the transportation aftermarket.

- Q:What's the difference between 304 stainless steel round bar and 304F stainless steel round bar?

- 304 stainless steel is a versatile stainless steel material. High temperature resistance is also good, the general use of temperature limit is less than 650 degrees centigrade. 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance.

- Q:Can stainless steel bars be stamped or pressed?

- Yes, stainless steel bars can be stamped or pressed.

- Q:Can stainless steel bars be used in the water treatment industry?

- Yes, stainless steel bars can be used in the water treatment industry. Stainless steel is highly corrosion resistant and can withstand exposure to water, making it an ideal material for various applications in water treatment facilities such as tanks, pipes, valves, and fittings. It offers durability, hygiene, and ease of maintenance, making it a popular choice for ensuring clean and safe water supply.

- Q:Are stainless steel bars suitable for water treatment applications?

- Yes, stainless steel bars are suitable for water treatment applications. Stainless steel is a corrosion-resistant material that can withstand exposure to various chemicals, including those commonly used in water treatment processes. It is also resistant to rust and staining, making it ideal for use in environments with high moisture levels. Additionally, stainless steel bars offer excellent strength and durability, ensuring they can withstand the demanding conditions often found in water treatment plants. Overall, stainless steel bars are a reliable and long-lasting choice for water treatment applications.

- Q:Do stainless steel bars have good machinability?

- Stainless steel bars are generally known for their good machinability. They possess excellent corrosion resistance and durability, which makes them highly sought after in various industries, including machining. To ensure consistent and predictable machining performance, manufacturers typically produce stainless steel bars with controlled compositions. These bars are available in different grades, each exhibiting its own unique machinability characteristics. While certain grades may require specialized tooling or techniques, with the right tools and expertise, stainless steel bars can be effectively machined. By employing appropriate cutting speeds, feeds, and lubrication, these bars can be turned, drilled, milled, or threaded with efficiency and accuracy. However, it is important to recognize that the machinability of stainless steel can vary depending on factors such as the specific grade, hardness, and heat treatment employed.

- Q:Can stainless steel bars be used in food preparation?

- Indeed, stainless steel bars are suitable for food preparation purposes. The utilization of stainless steel in food-related scenarios is widespread due to its sanitary characteristics and ability to resist corrosion. It remains unaffected by acidic or alkaline foods and does not introduce any flavors or odors into the prepared dishes. Furthermore, stainless steel is effortlessly cleaned and sanitized, rendering it an ideal material for bars, countertops, utensils, and other food preparation equipment. Moreover, stainless steel exhibits durability and longevity, making it a cost-efficient option for commercial kitchens and food processing establishments.

- Q:Can stainless steel bars be used in marine applications?

- Yes, stainless steel bars can be used in marine applications. Stainless steel is known for its corrosion-resistant properties, making it an ideal material for use in marine environments where it is constantly exposed to saltwater, moisture, and other corrosive elements. Stainless steel bars are commonly used in various marine applications such as boat fittings, marine hardware, anchor chains, propeller shafts, and other components that require high strength and resistance to corrosion. They are also chosen for their aesthetic appeal and durability, as stainless steel can maintain its appearance and structural integrity even in harsh marine conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Pipe Manufacturers in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords