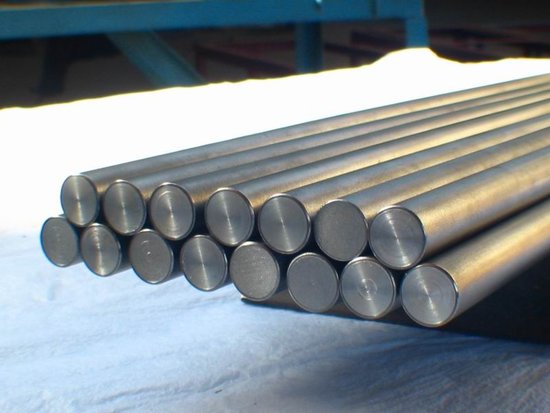

316Ti Stainless Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Bar

Stainless Steel Round Bright Bar

Hot-rolled Stainless Steel Black Bar

Grades:201、202、301、302、303、304、316、316L、321 etc

|

Diameter (mm) |

weight (kg/m) |

Diameter (mm) |

weight (kg/m) |

Diameter (mm) |

weight (kg/m) |

Diameter (mm) |

weight (kg/m) |

|

2 |

0.025 |

14 |

1.221 |

30 |

5.607 |

50 |

15.575 |

|

3 |

0.056 |

15 |

1.402 |

32 |

6.38 |

55 |

18.846 |

|

4 |

0.1 |

16 |

1.595 |

34 |

7.202 |

60 |

22.428 |

|

5 |

0.156 |

18 |

2.019 |

35 |

7.632 |

65 |

26.322 |

|

6 |

0.224 |

19 |

2.249 |

36 |

8.074 |

70 |

30.527 |

|

7 |

0.305 |

20 |

2.492 |

38 |

8.996 |

75 |

35.044 |

|

8 |

0.399 |

22 |

3.015 |

40 |

9.968 |

80 |

39.872 |

|

9 |

0.505 |

24 |

3.588 |

42 |

10.99 |

85 |

45.012 |

|

10 |

0.623 |

25 |

3.894 |

45 |

12.616 |

90 |

50.463 |

|

11 |

0.754 |

27 |

4.542 |

46 |

13.183 |

95 |

56.226 |

|

12 |

0.897 |

28 |

4.884 |

48 |

14.354 |

100 |

62.3 |

- Q:What are the physical properties of stainless steel bars?

- Stainless steel bars possess several distinct physical properties that make them desirable in various applications. Firstly, stainless steel bars have a high strength-to-weight ratio, making them exceptionally strong and durable while remaining relatively lightweight. This property allows stainless steel bars to withstand heavy loads and resist deformation, making them suitable for structural and load-bearing purposes. Another important physical property of stainless steel bars is their corrosion resistance. Stainless steel contains chromium, which forms a passive oxide layer on the surface of the material, protecting it from rust and corrosion. This property makes stainless steel bars highly resistant to moisture, chemicals, and environmental factors, making them ideal for use in harsh or corrosive environments. Additionally, stainless steel bars exhibit excellent heat resistance. They can withstand high temperatures without losing their strength or structural integrity. This property makes stainless steel bars suitable for applications where heat resistance is crucial, such as in industrial furnaces, heat exchangers, and automotive components. Furthermore, stainless steel bars have excellent machinability, which refers to their ability to be easily shaped, formed, and fabricated. This property allows stainless steel bars to be readily cut, welded, and shaped into various sizes and configurations, making them versatile for different applications. Lastly, stainless steel bars have an attractive appearance and a smooth surface finish. This property makes them visually appealing and suitable for decorative or aesthetic purposes, such as in architectural design, interior decoration, and jewelry making. In summary, the physical properties of stainless steel bars include high strength-to-weight ratio, corrosion resistance, heat resistance, excellent machinability, and an attractive appearance. These properties make stainless steel bars highly sought after in a wide range of industries, including construction, manufacturing, automotive, and design.

- Q:What are the different joining methods for stainless steel bars?

- There are several different joining methods that can be used for stainless steel bars, depending on the specific application and requirements. Some of the most common joining methods for stainless steel bars include: 1. Welding: This is one of the most widely used methods for joining stainless steel bars. It involves melting the edges of the bars and then allowing them to solidify, creating a strong bond. There are various welding techniques that can be used, such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and spot welding. 2. Adhesive bonding: This method involves using a high-strength adhesive to bond the stainless steel bars together. Adhesive bonding can be an effective joining method when the bars have complex shapes or when a more aesthetically pleasing appearance is desired. However, it may not be suitable for applications where high strength or resistance to extreme temperatures is required. 3. Mechanical fastening: This method involves using mechanical fasteners, such as bolts, screws, or rivets, to join the stainless steel bars together. Mechanical fastening can be a quick and cost-effective joining method, and it allows for easy disassembly if needed. However, it may not provide the same level of strength as welding or adhesive bonding. 4. Brazing: This method involves heating the stainless steel bars and then introducing a filler metal with a lower melting point, which flows between the bars and solidifies to create a joint. Brazing can be a good option when joining dissimilar metals or when a lower heat input is desired compared to welding. 5. Soldering: Similar to brazing, soldering involves using a lower melting point filler metal to join the stainless steel bars together. Soldering is typically used for lighter applications or when the bars have thinner sections, as it requires lower heat input compared to other joining methods. Each joining method has its own advantages and limitations, and the choice of method will depend on factors such as the desired strength, appearance, and specific requirements of the application. It is important to consider these factors and consult with experts to determine the most suitable joining method for stainless steel bars in a given situation.

- Q:Do stainless steel bars have good resistance to sulfuric acid?

- Yes, stainless steel bars have good resistance to sulfuric acid. Stainless steel is known for its corrosion-resistant properties and it is widely used in various industries due to its excellent resistance to many corrosive environments, including sulfuric acid. The high levels of chromium and nickel present in stainless steel help in forming a passive layer on the surface, which protects the material from the corrosive effects of sulfuric acid. Additionally, stainless steel has good mechanical strength and can withstand the high temperatures associated with sulfuric acid applications. However, it is important to note that the resistance of stainless steel to sulfuric acid depends on factors such as the concentration and temperature of the acid, so it is advisable to consult with experts or refer to the specific grade of stainless steel being used to determine its suitability for a particular sulfuric acid application.

- Q:What are the BITAUTO stainless steel bar?

- The carbon content in the stainless steel bar is also a key indicator of the hardness of stainless steel. The harder the carbon content is, the harder the material will be, and the opposite is the opposite.

- Q:What are the different types of stainless steel bars used in pharmaceutical equipment?

- Pharmaceutical equipment commonly utilizes various types of stainless steel bars due to their exceptional corrosion resistance and hygienic properties. Among the most frequently employed types are: 1. Austenitic Stainless Steel: This stainless steel variant boasts widespread usage in pharmaceutical equipment due to its superior corrosion resistance and remarkable formability. Its composition, enriched with substantial amounts of chromium and nickel, grants it resistance against diverse chemicals, rendering it ideal for applications necessitating optimal hygiene. 2. Martensitic Stainless Steel: Distinguished by its notable strength and hardness, this stainless steel variant contains a higher carbon content than austenitic stainless steel, endowing it with its characteristic robustness. Pharmaceutical equipment reliant on high mechanical strength often incorporates martensitic stainless steel. 3. Ferritic Stainless Steel: Renowned for its exceptional resistance to stress corrosion cracking and oxidation, ferritic stainless steel contains elevated levels of chromium, which confers commendable corrosion resistance. Pharmaceutical equipment requiring high temperature resistance frequently employs ferritic stainless steel. 4. Duplex Stainless Steel: By combining the properties of austenitic and ferritic stainless steels, duplex stainless steel strikes a balance between the two. It offers excellent corrosion resistance, high strength, and favorable weldability. Pharmaceutical equipment necessitating both corrosion resistance and strength often incorporates duplex stainless steel. The specific stainless steel bar employed in pharmaceutical equipment depends on the unique requirements of the application, including the chemicals or substances it may encounter, the desired level of hygiene, and the necessary mechanical strength.

- Q:Are stainless steel bars suitable for the automotive industry?

- Indeed, the automotive industry finds stainless steel bars to be a suitable choice. Stainless steel, a versatile and dependable material, offers numerous advantages for automotive purposes. It is renowned for its exceptional strength, durability, and ability to resist corrosion. Consequently, it becomes an ideal option for parts and components that must endure harsh environments and challenging conditions. For various applications in the automotive industry, stainless steel bars are commonly employed. These applications include the manufacturing of exhaust systems, suspension components, engine parts, and body panels. The high ratio of strength to weight that stainless steel possesses allows for the creation of lightweight yet robust components. This, in turn, enhances the fuel efficiency and overall performance of vehicles. Moreover, the resistance to corrosion that stainless steel possesses plays a crucial role in the automotive industry. Given that vehicles are exposed to moisture, chemicals, and other corrosive elements, this property ensures the longevity and reliability of automotive parts. As a result, maintenance and replacement costs are reduced. In addition, stainless steel bars can be easily machined and formed into intricate shapes. This provides manufacturers with design flexibility, enabling them to create innovative automotive components. Furthermore, the material is highly recyclable, aligning with the growing emphasis on sustainability and environmental consciousness in the automotive industry. To summarize, stainless steel bars are well-suited for the automotive industry due to their strength, durability, resistance to corrosion, design flexibility, and recyclability. Consequently, they are extensively utilized in various automotive applications, contributing to the production of high-quality and dependable vehicles.

- Q:Are stainless steel bars suitable for conveyor systems?

- Indeed, conveyor systems find stainless steel bars to be a suitable choice. Stainless steel, known for its durability and resistance to corrosion, proves to be an excellent option for the application of conveyors. It possesses the ability to endure harsh environments, including high temperatures, chemicals, or moisture, without compromising its strength or structural integrity. Moreover, stainless steel bars are effortless to clean and maintain, ensuring a conveyor system that is both hygienic and sanitary. Furthermore, these bars possess a remarkable load-bearing capacity, enabling them to handle heavy loads while facilitating the reliable and efficient transportation of materials. Ultimately, stainless steel bars emerge as a dependable and enduring choice for conveyor systems across various industries.

- Q:What is the difference between hexagonal and flat stainless steel bars?

- Hexagonal and flat stainless steel bars differ in shape and appearance. Hexagonal bars, as their name suggests, have a hexagonal cross-section, providing them with extra strength and stability. This makes them suitable for applications requiring higher load-bearing capacity or resistance to torsion. They also offer better grip and traction, commonly used in industries like construction, automotive, and machinery. On the contrary, flat stainless steel bars have a rectangular or square cross-section, making them more versatile for a wide range of uses. They are commonly found in architectural applications like handrails, balustrades, and decorative elements, as well as in manufacturing and fabrication processes. Their flat surface allows for easy machining, welding, and shaping. Another distinction lies in their aesthetic appeal. Hexagonal bars have a unique and distinctive look, making them popular for decorative purposes or when a visually appealing design is desired. Flat bars, on the other hand, have a more conventional appearance and are often chosen for their simplicity and versatility. Both hexagonal and flat stainless steel bars are widely available in the market, but their cost may vary based on factors such as stainless steel grade, dimensions, and quantity required. Ultimately, the choice between hexagonal and flat stainless steel bars depends on specific application requirements. Factors to consider include load-bearing capacity, resistance to torsion, ease of machining or welding, aesthetic preferences, and cost considerations.

- Q:Can stainless steel bars be customized?

- Indeed, specific requirements can be met by customizing stainless steel bars. Stainless steel, being a versatile material, can be readily adjusted to suit different applications. Options for customizing stainless steel bars include modifying their dimensions, shape, surface finish, and even the composition of the material. Furthermore, various fabrication techniques, including cutting, bending, welding, and machining, can be utilized to fabricate personalized stainless steel bars. This adaptability enables stainless steel bars to be tailored to satisfy precise industrial, construction, or design requirements.

- Q:Are stainless steel bars suitable for high-pressure applications?

- Yes, stainless steel bars are suitable for high-pressure applications. Stainless steel is known for its excellent strength, corrosion resistance, and ability to withstand high pressures. It is commonly used in industries such as oil and gas, chemical processing, and aerospace, where high-pressure conditions are a concern.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$8 million |

| Main Markets | East Asia, Middle East, West Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | above 50 people |

| Language Spoken: | English, Chinese, Arabic |

| b)Factory Information | |

| Factory Size: | about 15000 square meter |

| No. of Production Lines | above 4 |

| Contract Manufacturing | OEM Service Offered,Design Service Offered |

| Product Price Range | Average |

Send your message to us

316Ti Stainless Steel Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords