304 Stainless Steel Seamless Pipe Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

316 stainless steel pipe

Product Details | |

♦ Introduction | |

Stainless steel pipes, used outside, inside for decoration, construction, grade 201 202 301 304 | |

♦ Specifications | |

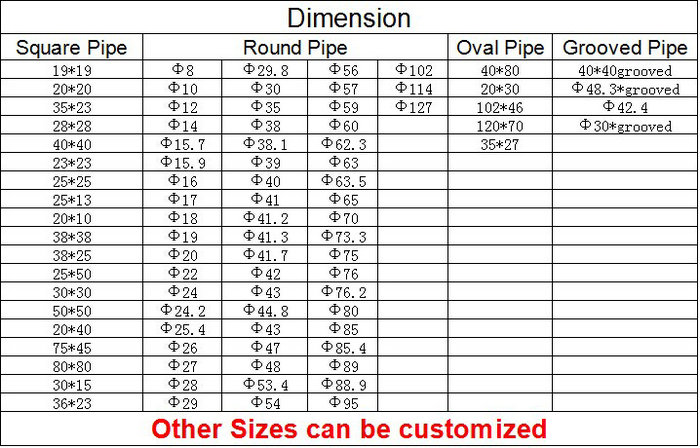

Round pipes - Outside diameter(mm) | |

8, 9.5, 11, 12, 12.7, 14.5, 15.9, 17, 18, 19, 20, 22, 23, 28, 29, 31.8 , 35, 36, 38, 45, 47, 48, 50.8, 60, 63, 76, 88.9, 102, 114, 133, 141, 159, 219 | |

Square pipes - Outside dimensions(mm) | |

10x10, 12x12, 15x15, 17x17, 18x18, 19x19, 20x20, 22x22, 23x23, 24x24, 25x25, 28x28, 30x30, 36x36, 38x38, 40x40, 48x48, 50x50, 60x60, 70x70, 80x80 | |

Rectangular pipes - Outside dimensions(mm) | |

20x10, 23x11, 24x12, 25x13, 28x13, 30x15, 34x22, 36x23, 37x24, 38x25, 40x20, 48x23, 50x15, 50x25, 60x15, 60x30, 73x43, 75x45, 95x45 | |

Wall Thickness | 0.3 - 3.0mm |

Length | 6m (or according to customers' requests) |

Polishing | 600#, 400#, 320#, 240#, 180#.etc. |

Tolerance | 1. Outer diameter: ±0.15mm 2. Thickness: ±10% of wall thickness |

Customized | Other size can be manufactured according to requirements |

Standard | Strictly follow the ASTM A 554 and others. |

Feature | |

1. Material of stainless steel: Grade: AISI 201, 202, 301,304, 304L, 316, 441, 409, 439M, 321, 430, 436L, etc. construction upholstery, and industry instruments (fencing, railing,safe doors / windows, gate fittings, inside staircases, balcony balustrades,furniture, sanitary wares, kitchen wares) | |

Implementation of Standards | |

1. GB in China; | |

Surface Type Processing | |

1. Surface polishing SB500#; | |

Products Show | |

| |

Mechanical Properties: MaterialY.S(N/MM2)T.S(N/MM2)ElongationHRB304>205>520>40<95304l>175>480>40<90316>205>520>40<90316l>175>480>40<90430>205>450>22<89

Applications: SurfaceApplication2BMedical equipment, Food industry, Construction material, Kitchen utensils.BAKitchen utensils, Electric equipment, Building construction.No.1Chemical tank, pipe.No.4Kitchen utensils, Building construction,Medical equipment.HLBuilding Construction.

|

| ---Packing & Transport--- Packing

Transport

|

- Q:Are stainless steel pipes resistant to scaling and pitting?

- Stainless steel pipes exhibit exceptional resistance to scaling and pitting, thanks to their remarkable corrosion resistance properties. This quality renders them highly durable and suitable for a wide range of applications, including pipe systems. The inclusion of chromium in stainless steel results in the formation of a protective layer of chromium oxide on the surface, effectively preventing the development of rust and corrosion. This protective layer effectively safeguards stainless steel pipes from scaling, which refers to the accumulation of tough mineral deposits on the inner surface of pipes. Furthermore, stainless steel pipes also exhibit resistance to pitting, which refers to the localized corrosion that manifests as small holes or pits on the surface of the pipe. Consequently, stainless steel pipes constitute an optimal choice for industries or applications wherein corrosion resistance is of utmost importance, such as water distribution systems, chemical processing plants, and oil and gas pipelines.

- Q:How do stainless steel pipes compare to carbon fiber pipes?

- Stainless steel pipes possess distinct qualities and find usage in diverse fields. Renowned for their robustness and power, they exhibit exceptional resistance to corrosion and can withstand elevated temperatures and pressures. Consequently, they prove suitable for various industries, including oil and gas, chemical, and construction. Boasting an elongated lifespan and the ability to bear heavy loads, stainless steel pipes emerge as a reliable option for numerous applications. Nevertheless, their relatively hefty weight necessitates additional support structures. Conversely, carbon fiber pipes, characterized by their lightness and high strength-to-weight ratio, serve as an alternative. Crafted from carbon fibers embedded in a resin matrix, they yield a formidable and rigid material. Aerospace, automotive, and sports equipment industries commonly employ carbon fiber pipes. Their lightweight nature permits enhanced fuel efficiency in vehicles and augmented performance in sports equipment. However, carbon fiber pipes prove pricier than their stainless steel counterparts and may lack the desired resilience to extreme temperatures or corrosive surroundings. To summarize, stainless steel pipes excel in durability and corrosion resistance, making them well-suited for demanding tasks. Carbon fiber pipes, on the other hand, offer lightweight construction and a commendable strength-to-weight ratio, rendering them ideal for weight reduction-focused applications. Ultimately, the choice between stainless steel and carbon fiber pipes hinges on specific requirements and the trade-offs between cost, weight, and performance.

- Q:How do you calculate the wall thickness for stainless steel pipes under external pressure?

- To calculate the wall thickness for stainless steel pipes under external pressure, you can use the formula provided by various industry codes and standards such as ASME B31.3 or API 570. This formula takes into account factors like the material's yield strength, allowable stress, design factor, and the external pressure acting on the pipe. By inputting these values into the formula, you can calculate the required wall thickness to ensure the pipe can withstand the external pressure without failure.

- Q:Can stainless steel pipes be embossed?

- Certainly, it is possible to emboss stainless steel pipes. Embossing refers to the technique of raising or pressing a pattern or design into a material like stainless steel, with the intention of creating a decorative or functional effect. This technique can be applied to a wide range of metal surfaces, including stainless steel pipes. To achieve this, specialized machinery and tools are employed to imprint the desired design onto the pipe's surface. The purpose of embossing can be twofold: it may enhance the visual appeal and texture for aesthetic reasons, or provide functional benefits like improved grip and slip prevention. In summary, embossing stainless steel pipes is indeed viable and can yield diverse desired outcomes.

- Q:Can stainless steel pipes be electropolished?

- Yes, stainless steel pipes can be electropolished. Electropolishing is a process that can be applied to stainless steel pipes to enhance their surface finish, remove impurities, and improve corrosion resistance. It involves immersing the pipes in an electrolyte solution and applying an electric current to remove a controlled layer of metal from the surface, resulting in a smooth and polished finish.

- Q:Can stainless steel pipes be used for steam systems?

- Stainless steel pipes are indeed suitable for steam systems due to their remarkable resistance to corrosion and high temperatures. This material is renowned for its ability to carry steam without deteriorating or corroding, thus ensuring the efficiency and safety of the steam system. Moreover, stainless steel pipes possess low thermal conductivity, which aids in reducing heat loss during the transportation of steam. Consequently, these pipes are highly favored in diverse industries for their durability, reliability, and long lifespan.

- Q:Can stainless steel pipes be lined with polyethylene?

- Yes, stainless steel pipes can be lined with polyethylene. This lining provides additional corrosion resistance to the stainless steel pipes, making them suitable for various applications in industries such as oil and gas, water treatment, and chemical processing.

- Q:What is the difference between seamless and extruded stainless steel pipes?

- The main difference between seamless and extruded stainless steel pipes lies in their manufacturing process. Seamless stainless steel pipes are produced by piercing a solid billet of stainless steel and then rolling it to the desired shape and size without any seams. On the other hand, extruded stainless steel pipes are created by forcing the molten stainless steel through a die to form the desired shape. This process results in a seamless pipe with consistent thickness throughout. In summary, seamless pipes are made by rolling a solid billet while extruded pipes are formed by forcing molten stainless steel through a die.

- Q:What wire is used for welding of 316 stainless steel line?

- Inspection of assembly and tack welds;1, check the geometry and shape after assembly, whether it conforms to the provisions of the drawings. :2, assembly and assembly clearance is 1.5 - 2mm, using TIG welding, three point positioning welding,The welding seam position for the clock 3 points, 9 points and 12 points, the welding materials used should be the same as the welding materials, welding length is 10 15mm, welding requirements and guarantee no defect, the wrong side is less than 1.5 2mm.3, the group is not allowed to use strong assembly, the joint wall must be flush.4, when welding, there must be no air, slag, tungsten and crack.

- Q:Are stainless steel pipes resistant to scaling?

- Indeed, scaling is effectively resisted by stainless steel pipes. This term denotes the development of a solid, substantial coating of mineral deposits on the internal surface of pipes, leading to diminished efficiency and restricted fluid flow. Stainless steel pipes possess remarkable resistance to scaling, thanks to their composition that usually incorporates chromium. The inclusion of chromium initiates the creation of a safeguarding oxide layer on the pipe's surface, which hinders scale formation and guarantees enduring durability. Moreover, stainless steel pipes exhibit exceptional corrosion resistance, rendering them highly suitable for various applications prone to scaling.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 Stainless Steel Seamless Pipe Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords