220V Single Phase 0.75kw 1 hp AC Drive (Frequency Converter/Inverter)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

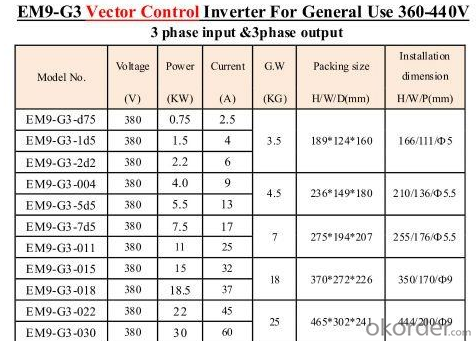

Place of Origin: | Guangdong, China (Mainland) | Brand Name: | EMHEATER | Model Number: | EM9 series vector frequency inverter |

Output Power: | 0.4kW--630kW | Output Type: | Triple | Size: | As per product |

Weight: | 3--500KG | Input Voltage: | 220V-240V;320V-480V;560V-690V | Output Voltage: | 220V-240V;320V-480V;560V-690V |

Type: | DC/AC Inverters | Output Frequency: | 0--800HZ | Output Current: | 2.5--1100A |

Color: | Black | Certificate: | CE-EMC and CE-LVD | IGBT: | All Model are Integrated IGBT |

Control mode: | Vector control/ VF control |

Packaging & Delivery

Packaging Details: | standard carton/crate package |

Delivery Detail: | Within 3-5days after receiving the payment |

Specifications:

Vector control frequency Inverter,

All model are integrated IGBT,

Built-in RS485 card, and approved by CE,

and optional displaying 4 lines keypad.

Products Features:

Input Voltage Range:380/220V±15%

Input Frequency Range:47~63Hz

Output Voltage Range:0~rated input voltage

Output Frequency Range:0~600Hz

Overload Capacity:60s with 150% of rated current, 10s with 180% of rated current.

Self study motor parameter function

Control Mode: Sensorless Vector Control (SVC); Constant Torque; V/F Control.

Speed Accuracy: Sensorless Vector Control :±0.5% of maximum speed (SVC)

Starting Torque: 150% of rated torque at 0.5Hz (SVC).

Programmable Timing Running(Simple PLC)

All model are integrated IGBT, and optional displaying 4 lines keypad.

The malfunction ratio is 0.1% within 18 months warranty.

All the above items have been passed the CE-EMC and CE-LVD certificate; you will enjoy desirable using and a guaranteed after-sale service.

Which kind of voltages frequency grade we can provide?

1 Phase input, 3 phase output, 200-240V, 0.75-7.5KW

3 Phases input, 3 phase output 200-240V, 0.75-500KW

3 Phases input, 3 phase output 380-415V, 0.75-630KW

3 Phases input, 3 phase output 420-480V, 0.75-630KW

3 Phases input, 3 phase output 575-690V, 11-630KW

FAQ:

What is the minimium quantity?

10 units.

2. How many days do you need to produce?

We can delivery the goods within 5 days after receiving your payment.

- Q:Old printing machine transformation, 37KW6 polar frequency motor with brake, inverter 55KW, now found running,

- May be mechanical part of the card, try idling motor.

- Q:Which machines are used for the frequency converter

- Frequency converter is widely used in the speed regulation of AC motor.Varameter speed control technology is an important development direction of modern power transmission technology, with the development of power electronics technology, AC frequency conversion technology from theory to practice gradually mature. Inverter not only smooth speed, large range, high efficiency, start current is small, smooth operation, and energy saving effect is obvious. Therefore, the exchange frequency control has gradually replaced the traditional traditional slip speed, variable speed control, DC speed control system, more and more widely used in metallurgy, textile, printing and dyeing, smoke machine production lines and buildings, Water supply, air conditioning and other fields.

- Q:How to view your own laptop power adapter is how much tile?

- 1, the power adapter has a logo, you can find their own look, close to the paper or direct letterpress printed with the voltage, current and power. If there is no write power, the direct voltage multiplied by the current is the maximum power. 2, if the power adapter only identifies the output voltage is 20V, the output current is 4.5A, then we formula W (power) = V (voltage) xI (current) to calculate. Calculate the formula with a power to know the output power is 20 × 4.5 = 90W.

- Q:Can the inverter stop intermittently during operation? If so, how to connect and set up

- Look at your inverter manual, because the inverter is not a simple wiring can run, first of all have to know that a few are external terminals (inverter input terminals),

- Q:If it is 8-pole variable frequency motor, enter the motor nameplate parameters in the inverter input for the 4 pole can?

- Motor brand above all, the general number of wrong is the inverter shows the speed is not right, for the speed control requirements are not high places will not be a problem, you can use

- Q:Acer laptop power adapter

- It might be bad, you have to determine whether the adapter or adapter adapter directly change.

- Q:4 pole 380V 4-5.5KW frequency conversion motor and inverter about how much money, such as the use of electromagnetic speed motor comparison

- About 2,000 yuan, electromagnetic speed and vector inverter can bring feedback

- Q:On the notebook power adapter output current and voltage issues

- On the real virtual cable that adapter is rectifier filter output, no regulator, the notebook internal regulator, the adapter does not need to regulator. 3.25A is smaller than 4.5A, because the adapter has a power margin that can be used. Summer attention to touch the adapter surface is overheating. Conditional or buy a large number of good current.

- Q:Laptop power adapter repair how much money

- Look at your warranty period had no, no contact the seller can be free for a new one. If there is no need to repair the warranty period. Now the maintenance point is too lazy to repair. Suggest you follow your computer brand with a new one Because the maintenance fee to buy a difference can not be much money and the quality is not guaranteed, a power adapter is now dozens of dollars

- Q:East yuan 7200GS inverter start 11KW 4-pole motor and 2-pole motor need to modify what parameters?

- 11KW 4-pole motor and 2-pole motor is the difference between the motor coil winding is not the same, the appearance of the 2-pole motor to be slightly larger, the speed of 4 pole speed is 1450 r / min, 2 pole is 970 r / min

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

220V Single Phase 0.75kw 1 hp AC Drive (Frequency Converter/Inverter)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords