201 Bright Annealing Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

AISI,EN

Technique:

Cold Rolled

Shape:

Round

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

1.2

Length:

1000

Outer Diameter:

12.8

Net Weight:

9

Detailed information--Stainless Steel Pipe

| Description | stainless steel pipe, stainless steel tube |

| Type | 201,202,304,316,310,409,410,420,430,SAF2205,S31803 |

| Thickness | 0.25-10mm |

| Length | 3-6m or as customized |

| Outer diameter | 6-508mm |

size (round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 159, 168, 219 mm or as customized |

| size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or as customized |

| size (oval pipe) | 30×15,80×40 mm or as customized |

| Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

| Finishing | Mill, Polished, Mirror, #600 |

Other information--Stainless Steel Pipe

| Certificate | BV, ISO, CE |

| Productivity | 800 tons/ day |

| Packing | Standard export sea-worthy packing |

| Delivery time | 10-30 days |

| Note | Stainless steel pipe can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

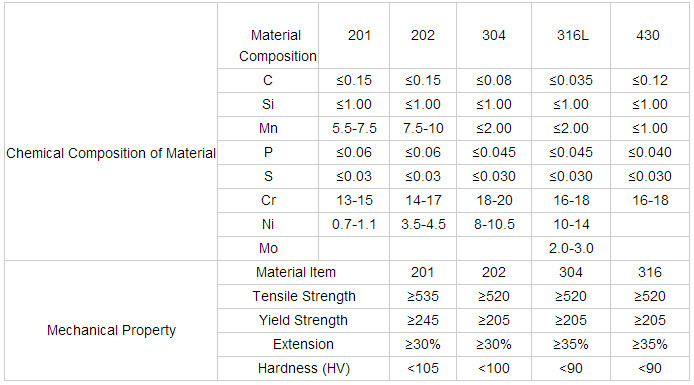

Chemical composition--Stainess Steel Pipe

- Q:Are stainless steel pipes suitable for food processing applications?

- Yes, stainless steel pipes are highly suitable for food processing applications. This is because stainless steel is resistant to corrosion, easy to clean and sanitize, and does not react with food or alter its taste. Additionally, stainless steel pipes comply with hygiene and safety standards, making them ideal for the food industry.

- Q:What are the common joining methods for stainless steel pipes?

- The common joining methods for stainless steel pipes include welding, threaded connections, and flanged connections. Welding is the most common and widely used method for joining stainless steel pipes. It involves melting the ends of the pipes and fusing them together using a welding electrode. The weld can be made using various types of welding techniques such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or Stick welding, depending on the specific requirements of the application. Threaded connections are another popular joining method for stainless steel pipes, especially for smaller diameter pipes. This method involves threading the ends of the pipes and using threaded fittings to connect them. Threaded connections provide a secure and leak-proof joint, and they are relatively easy to install and disassemble when necessary. Flanged connections are used for larger diameter stainless steel pipes or when there is a need for easy disassembly and reassembly. This method involves attaching flanges to the ends of the pipes and connecting them using bolts and gaskets. Flanged connections provide a rigid and reliable joint, and they are commonly used in industrial applications where frequent maintenance or replacement is required. It is important to note that the choice of joining method for stainless steel pipes depends on various factors such as the pipe diameter, pressure and temperature requirements, accessibility, and the specific application. Consulting with a qualified engineer or professional is recommended to ensure the most appropriate joining method is selected for a specific project.

- Q:How can stainless steel and copper pipe be welded?

- First, try the test before burning. The brass is directly burned to the stainless steel tube. First feel the heat and see what the stainless steel likes to adhere toWhen stainless steel is not red, copper is not adheredWhen stainless steel is red, do not stick copperOnly when stainless steel is red, copper paste is preferredTherefore, when welding, we must master the size of the furnace, thin and thin pipe, fire should be adjusted to small crude pipe, on the contrary, they feel the proper heat

- Q:Can stainless steel pipes be insulated for soundproofing?

- Indeed, soundproofing stainless steel pipes is possible. By insulating these pipes, the transmission of noise and vibrations through them can be effectively reduced. Several methods and materials are available for insulating the pipes, including acoustic wraps, foam insulation, and mass-loaded vinyl. These materials are specifically designed to absorb or obstruct sound waves, preventing their propagation along the pipes and into the surrounding area. Adequately insulating stainless steel pipes can greatly enhance soundproofing in residential, commercial, or industrial environments, making them a viable and efficient solution for noise reduction.

- Q:Can stainless steel pipes be used for dairy processing plants?

- Certainly! Dairy processing plants can indeed utilize stainless steel pipes. Stainless steel is highly favored in the food and beverage sector, including dairy processing plants, because of its exceptional resistance to corrosion, durability, and hygienic qualities. Dairy products do not cause any reaction with stainless steel pipes, and these pipes can endure the rigorous cleaning and sanitization procedures necessary in such facilities. Moreover, stainless steel pipes possess a smooth surface that reduces the likelihood of bacterial growth and enables effortless cleaning and upkeep. Consequently, stainless steel pipes are a fitting and frequently employed choice in dairy processing plants.

- Q:How do stainless steel pipes compare to plastic pipes?

- Stainless steel pipes and plastic pipes possess distinct qualities that differentiate them in terms of durability, flexibility, cost, and environmental impact. Concerning durability, stainless steel pipes exhibit high resistance to corrosion, rust, and extreme temperatures, making them well-suited for both indoor and outdoor applications. Conversely, plastic pipes are susceptible to degradation caused by UV exposure, chemical reactions, and high temperatures, potentially resulting in leaks or ruptures over time. Flexibility is another critical aspect to consider. Stainless steel pipes are inflexible and not ideal for installations that necessitate bending or maneuvering around obstacles. In contrast, plastic pipes offer great flexibility, easily bendable or curved, allowing for convenient installation in complex or tight spaces. Cost often plays a determining role when choosing between stainless steel and plastic pipes. Initially, stainless steel pipes tend to be more costly due to higher raw material and manufacturing expenses. However, they boast a longer lifespan and require less maintenance, balancing out the initial investment. On the other hand, plastic pipes are generally more affordable but may necessitate frequent replacements or repairs, leading to cumulative costs over time. Finally, environmental impact is a crucial factor in today's environmentally conscious world. Stainless steel pipes are recyclable and possess a lengthy life expectancy, minimizing waste and reducing the need for replacements. Conversely, plastic pipes, despite being partially recyclable, often end up in landfills due to their shorter lifespan and limited recycling capabilities. Consequently, stainless steel pipes are deemed more environmentally friendly. In conclusion, stainless steel pipes offer superior durability, corrosion resistance, and long-term cost-effectiveness. However, plastic pipes are more flexible, initially more affordable, and suitable for specific applications. Ultimately, the selection between stainless steel and plastic pipes depends on the project's specific needs, budget, and environmental considerations.

- Q:Classification, advantages and disadvantages of stainless steel welding

- The utility model has the advantages of universal use and easy operation, and is mainly regulated by people, and the welding seam material is an electric welding strip. Manual welding can weld almost all of the material, even outdoors, so it has good adaptability and is usually powered by direct current.Welding, either titanium type electrode, can also be sealed. The titanium electrode is easy to weld, the welding seam is beautiful, and the welding slag is easy to remove. But the drawback is that if you do not use it for a long time, you must bake it again to prevent moisture accumulation.

- Q:What is the difference between sanitary and industrial stainless steel pipes?

- The primary distinction between sanitary and industrial stainless steel pipes lies in their intended purposes and the level of cleanliness needed. Sanitary stainless steel pipes are specifically designed for use in industries such as food and beverage, pharmaceuticals, and other environments where cleanliness and hygiene are crucial. These pipes are manufactured with a higher degree of surface finish, typically smooth and polished, to prevent bacterial growth and ensure easy cleaning. The inner surface of sanitary pipes is often electropolished to further enhance its smoothness and resistance to corrosion. Additionally, sanitary pipes are often equipped with tri-clamp fittings or other sanitary connections to facilitate easy disassembly for cleaning purposes. On the contrary, industrial stainless steel pipes find application in a diverse range of industries, including manufacturing, oil and gas, chemical processing, and construction. These pipes are usually designed to withstand high pressures, extreme temperatures, and harsh environments. Industrial pipes may have a rougher surface finish and may not require the same level of cleanliness as sanitary pipes. They are often welded or threaded together for assembly and are built to withstand heavy-duty usage. In conclusion, the main differences between sanitary and industrial stainless steel pipes can be found in their intended purposes, surface finish, and the level of cleanliness required. Sanitary pipes prioritize hygiene and easy cleaning, making them well-suited for food and pharmaceutical applications. Industrial pipes, on the other hand, focus on durability and strength to endure demanding industrial environments.

- Q:What are the different types of fittings used with stainless steel pipes?

- There are several different types of fittings that can be used with stainless steel pipes, depending on the specific application and requirements. Some of the most common types include: 1. Compression fittings: These fittings are designed to create a leak-proof connection by compressing a ferrule onto the pipe. They are easy to install and can be used with both rigid and flexible stainless steel pipes. 2. Threaded fittings: Also known as screwed fittings, these fittings have female threads that allow them to be screwed onto the male threads of the pipe. They are commonly used in low-pressure applications and can be easily installed or removed. 3. Butt weld fittings: These fittings are used to create a permanent, welded connection between two stainless steel pipes. They require the pipes to be beveled to create a V-shaped groove and are typically used in high-pressure or high-temperature applications. 4. Flange fittings: Flanges are used to connect two stainless steel pipes or to connect a pipe to a valve, pump, or other equipment. They provide a strong and leak-proof connection and can be easily bolted or welded onto the pipe. 5. Push-to-connect fittings: These fittings are designed to provide a quick and easy connection without the need for tools or soldering. They use a push-in mechanism to secure the pipe and are commonly used in plumbing and air compression systems. 6. Camlock fittings: Camlock fittings are used to quickly connect or disconnect hoses and pipes. They have a lever or cam mechanism that locks the fitting into place, ensuring a secure connection. They are commonly used in industrial applications where frequent connections and disconnections are required. Overall, the choice of fitting will depend on factors such as the application, pressure requirements, and ease of installation. It is important to select the appropriate fitting to ensure a reliable and durable connection for stainless steel pipes.

- Q:Can stainless steel pipes be used for cryogenic applications?

- Cryogenic applications can indeed utilize stainless steel pipes. Stainless steel is widely recognized for its exceptional properties at low temperatures, including admirable strength, flexibility, and resistance against corrosion. These qualities render stainless steel pipes suitable for the transportation and storage of cryogenic fluids, like liquid nitrogen, oxygen, or argon. The high strength-to-weight ratio of stainless steel permits the construction of lightweight and durable cryogenic systems. Furthermore, stainless steel pipes can endure the extreme temperature gradients and thermal stresses commonly encountered in cryogenic applications. Nevertheless, it is crucial to select the appropriate grade of stainless steel specifically engineered for cryogenic service to ensure optimal performance and safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

201 Bright Annealing Stainless Steel Pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords