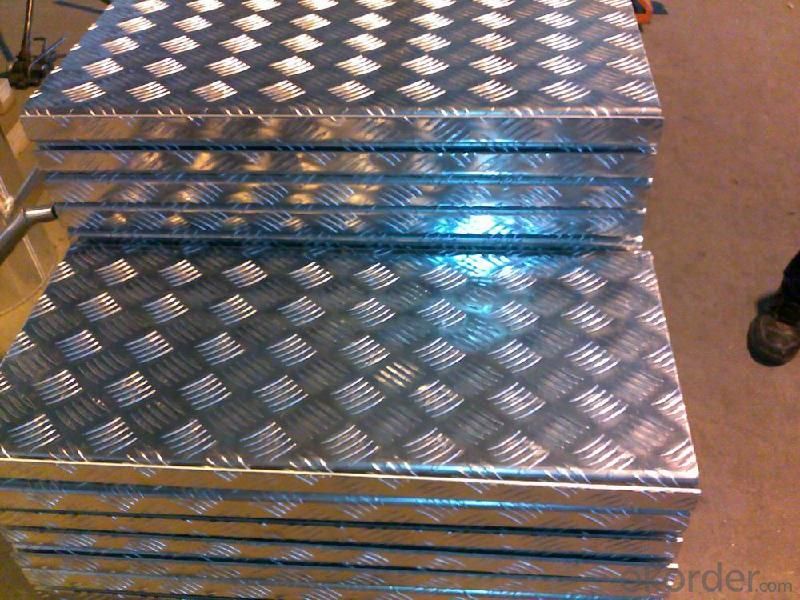

1mm 2mm Aluminum Sheet with Film Protection 1050 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminum Sheet for Making Aluminum Composite Panel

Aluminum sheet specifications:

1) Alloy : 1050 1060 1070 1100 2024 3003 3004 3105 3A21 5005 5052 5083 5754 5182 5454 5456 6061 6063 7075 8011 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 300mm

4) Width:20mm to 3300mm

5)Length: ≤ 12000mm

6) Protective film can be added

7) Production Line: DC and CC production line

Discription:

Width: 50-800mm

Thickness: 8-25mic

Length: 3-300m

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q:Are aluminum sheets suitable for aerospace wing structures?

- Indeed, aerospace wing structures can be appropriately constructed using aluminum sheets. The aerospace industry extensively employs aluminum owing to its exceptional ratio of strength to weight, resistance to corrosion, and capacity to endure high temperatures. Wing structures in particular often utilize aluminum alloys like 2024 and 7075 for their remarkable strength and endurance. Moreover, aluminum can be conveniently shaped and sized into various configurations, facilitating the creation of intricate wing designs. Consequently, aluminum sheets provide a convergence of lightweight properties, strength, and dependability, rendering them exceptionally well-suited for aerospace wing structures.

- Q:What kind of material is 2A12 aluminum sheet?

- Corrosion resistance is poor, but it can be effectively protected by pure aluminum coating. It is easy to crack when welding, but it can be welded or riveted by special process. Widely used in aircraft structures, rivets, truck hubs, propeller components, and many other structures.

- Q:Can aluminum sheets be used for electrical enclosures?

- Yes, aluminum sheets can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, corrosion resistance, and lightweight properties. It is a good conductor of electricity, allowing for efficient distribution of electrical current within the enclosure. Additionally, aluminum has a high resistance to corrosion, making it suitable for outdoor and harsh environment applications. Its lightweight nature also makes it easier to handle and install. Overall, aluminum sheets are a reliable and commonly used material for electrical enclosures.

- Q:What is the typical electrical conductivity of aluminum sheets?

- Aluminum sheets typically exhibit an electrical conductivity ranging from 35.0 to 45.0 MS/m (mega siemens per meter) or 35,000 to 45,000 S/m (siemens per meter). Renowned for its exceptional electrical conductivity, aluminum possesses approximately 61% of the conductivity found in copper. As a result, aluminum is extensively used in diverse electrical applications, including wiring, power transmission lines, electrical busbars, and electrical equipment components. The conductive nature of aluminum facilitates the seamless and dependable flow of electric current, rendering it an invaluable material within the electrical industry.

- Q:Can aluminum sheets be bent without breaking?

- Aluminum sheets possess the remarkable ability to endure bending without shattering. As a metal, aluminum boasts exceptional malleability and ductility, rendering it effortlessly moldable and pliable. This quality renders aluminum an optimal substance for a wide array of purposes, encompassing the production of aircraft, automobiles, and household articles. The pliability of aluminum sheets facilitates the crafting of intricate designs and intricate forms, establishing it as an exceptionally adaptable substance. It is, nonetheless, worth mentioning that the thickness and caliber of the aluminum sheet may impact its susceptibility to bending. Thicker sheets may necessitate increased force and specialized tools to achieve the desired curvature, whereas softer aluminum grades may yield to bending with greater ease.

- Q:What are the different alloys available for aluminum sheets?

- There are several alloys available for aluminum sheets, including 1100, 3003, 5052, and 6061. Each alloy has different properties and characteristics, making them suitable for various applications.

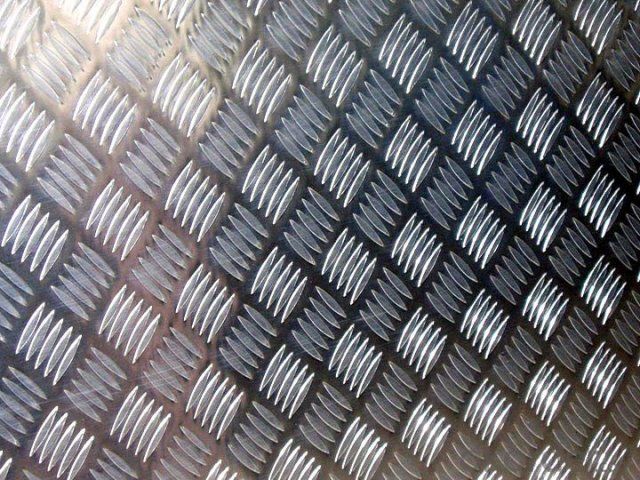

- Q:Can aluminum sheets be used for flooring?

- Yes, aluminum sheets can be used for flooring. Aluminum is a lightweight and durable material that can withstand heavy foot traffic and is resistant to corrosion. It is commonly used for industrial flooring, outdoor decks, and transportation platforms.

- Q:What are the different types of alloys used in aluminum sheet?

- There are several different types of alloys used in aluminum sheet. Some of the most commonly used alloys include: 1. 3003 alloy: This alloy is known for its excellent resistance to corrosion and is often used in applications where exposure to moisture is a concern. It is also easy to form and weld, making it a popular choice for various structural components. 2. 5052 alloy: This alloy is highly corrosion-resistant and has good formability. It is often used in marine and automotive applications, as well as in architectural elements. 3. 6061 alloy: This alloy offers excellent strength and is commonly used in applications that require high structural integrity. It is often used in aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. 7075 alloy: This alloy is known for its high strength-to-weight ratio and is often used in aerospace and defense applications. It is also used in the manufacturing of bicycle frames, rock climbing equipment, and other high-performance applications. 5. 2024 alloy: This alloy is known for its high strength and excellent fatigue resistance. It is often used in aerospace applications, as well as in the production of structural components and fasteners. These are just a few examples of the many different types of alloys used in aluminum sheet. Each alloy has its own unique properties and advantages, making it suitable for specific applications and industries.

- Q:Aluminum wiring can be a fire hazard because it can oxidize, or combine with oxygen..

- Well, aluminum oxide is Al2O3, right? So for every 2 aluminum atoms there are 3 oxygen atoms, So, if you have three moles of aluminum, you'll need 4 and a half moles of oxygen to react completely with the aluminum. One mole of oxygen atoms weighs 16 grams, so 4.5 moles weighs 72 grams, right? Now it could be that your teacher told you three point zero zero moles of aluminum to get you to use two significant figures, so if you've studied significant figures you may want to look up a more accurate number for the atomic weight of aluminum, and carry the calculation through to three significant figures. Otherwise, 72 is a fine answer.

- Q:Are aluminum sheets suitable for aerospace structural components?

- Aerospace structural components can indeed be made from aluminum sheets. Aluminum is a material that is both lightweight and durable, and it has been used extensively in the aerospace industry for many years. Its exceptional strength-to-weight ratio makes it highly desirable for a range of applications in aircraft manufacturing. Aluminum sheets provide numerous advantages for aerospace structural components. Firstly, their lightweight nature helps to reduce the overall weight of the aircraft. This is crucial for improving fuel efficiency, increasing payload capacity, and enhancing overall performance. Additionally, the lightweight quality of aluminum sheets makes them easier to handle and assemble during the manufacturing process. Secondly, aluminum exhibits excellent resistance to corrosion. This is particularly important for aerospace applications, as the components are exposed to various environmental conditions, such as high humidity, extreme temperatures, and exposure to chemicals. The corrosion resistance of aluminum ensures that the structural components remain durable and long-lasting, reducing the need for frequent maintenance and replacement. Furthermore, aluminum is a highly malleable material, allowing for easy shaping and forming into complex structures. It can be bent, cut, and fabricated with ease to meet specific design requirements, making it versatile for a variety of aerospace applications. The ability to form intricate shapes with aluminum sheets enables engineers to design efficient and streamlined structures, optimizing aerodynamics and minimizing drag. Another advantage of aluminum sheets is their excellent thermal conductivity. This property enables efficient heat dissipation, which is crucial in aerospace applications where components may be exposed to high temperatures generated during flight or engine operation. The thermal conductivity of aluminum helps to prevent overheating and ensures the structural integrity of the components. In conclusion, the lightweight, corrosion resistance, malleability, and thermal conductivity properties of aluminum sheets make them highly suitable for aerospace structural components. These characteristics contribute to the overall performance, efficiency, and safety of aircraft, making aluminum an ideal material for various applications in the aerospace industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1mm 2mm Aluminum Sheet with Film Protection 1050 1100 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords