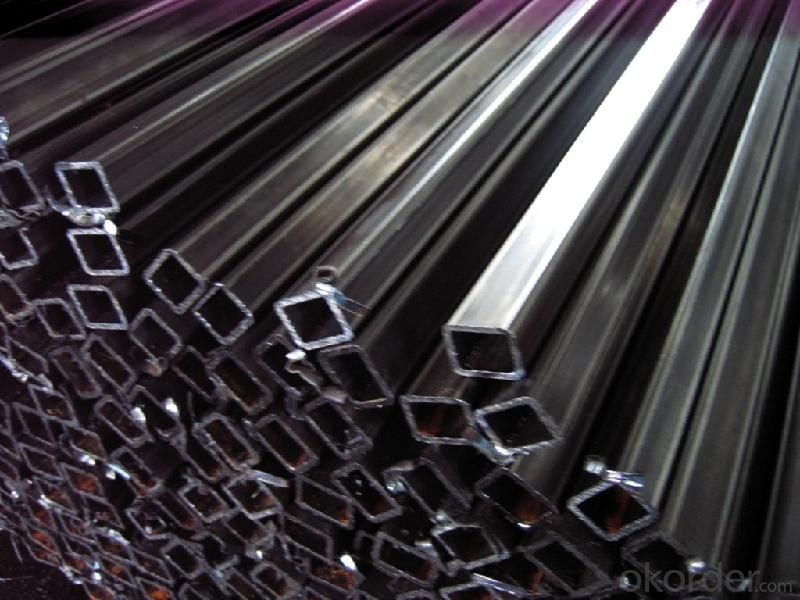

12mm*1.13kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

We offer Square Steel Bar with grade Q195 / Q235

Specifications of Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

Chemical Composition:

-Chemical Composition. Q195

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

-Chemical Composition. Q235

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures and Tolerances of Square Steel Bar:

(The section of Square Steel Bar)

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

- Q:What are some common uses for a steel square in box joint construction?

- A steel square is an essential tool in box joint construction and is used for a variety of purposes. Some common uses for a steel square in box joint construction include: 1. Layout and marking: A steel square is used to accurately mark and measure the dimensions of the box joint. It helps in setting up the appropriate size and spacing of the finger joints and ensures precision in the layout. 2. Checking for squareness: The steel square is utilized to check the squareness of the corners in box joint construction. This ensures that the joints are perfectly perpendicular and will result in a strong and sturdy box. 3. Aligning and guiding: When assembling the box joint, a steel square can be used to align and guide the pieces together. It helps to maintain the correct angle and ensures that the joints fit snugly, resulting in a tight and secure box. 4. Testing for flatness: The steel square can also be used to test the flatness of the joint surfaces. By placing the square against the surfaces, any gaps or irregularities can be detected and corrected before final assembly. 5. Cutting and sawing: A steel square can be used as a guide for cutting and sawing the box joint. It provides a straight edge for the saw or router, ensuring clean and accurate cuts along the joint lines. Overall, a steel square is an indispensable tool in box joint construction. It helps in layout, alignment, checking for squareness, and ensuring precision cuts, resulting in a well-fitted and strong box joint.

- Q:Can a steel square be used for checking the squareness of a door frame corner?

- Yes, a steel square can be used to check the squareness of a door frame corner.

- Q:What are some common mistakes to avoid when using a steel square?

- When using a steel square, there are a few common mistakes that should be avoided to ensure accurate measurements and precise angles. Here are some of the most frequent errors: 1. Not checking for squareness: One of the common mistakes is assuming that the steel square is perfectly square and not double-checking its accuracy. It is essential to verify its squareness by comparing it to a known square or using a precision instrument like a digital angle gauge. 2. Improper placement: Incorrect placement of the steel square can lead to inaccurate measurements. It is crucial to ensure that the square is aligned properly with the workpiece or the surface being measured. Placing it firmly against the edge or corner is necessary to obtain accurate results. 3. Misreading measurements: Another common mistake is misreading the measurements on the steel square. These squares typically have various scales and markings on different sides, so it is important to familiarize yourself with how to read them correctly. Using the wrong scale or misinterpreting the markings can result in incorrect measurements. 4. Inconsistent pressure: When marking or scribing lines with a steel square, inconsistent pressure can lead to inaccurate results. Applying uneven pressure or not holding the square firmly against the workpiece can cause the square to shift, resulting in imprecise lines. 5. Neglecting to clean and maintain the square: Over time, dirt, dust, and rust can accumulate on the steel square, affecting its accuracy. It is essential to regularly clean and maintain the square to ensure that it functions properly. Using a soft cloth and a mild cleaning solution can help remove any debris or rust. 6. Not using the square for its intended purpose: Lastly, using the steel square for tasks it is not designed for can lead to mistakes. Steel squares are primarily used for measuring and marking right angles, so trying to use them for other angles or complex measurements may result in errors. It is important to choose the appropriate tool for the specific task at hand. By being aware of these common mistakes and taking the necessary precautions, you can effectively use a steel square and achieve accurate measurements and precise angles in your projects.

- Q:What are some common uses of a steel square in welding?

- A steel square is commonly used in welding for various purposes such as measuring and marking angles, checking the accuracy of right angles, ensuring squareness of joints or corners, and aligning or setting up workpieces. It is a versatile tool that helps welders maintain precision and accuracy in their work.

- Q:Can a steel square be used for checking the squareness of a hand saw blade?

- No, a steel square cannot be used for checking the squareness of a hand saw blade. A steel square is primarily used for measuring and marking right angles, whereas checking the squareness of a hand saw blade requires a specialized tool called a saw set or a square filing guide. These tools are specifically designed to ensure the correct angle and squareness of the teeth on a hand saw blade for optimal cutting performance.

- Q:Can a steel square be used for checking the squareness of a window frame corner?

- Yes, a steel square can be used to check the squareness of a window frame corner. A steel square is a tool commonly used by carpenters and builders to ensure that corners are perfectly square. It has a 90-degree angle that allows for accurate measurement and checking of right angles. By placing the steel square against the window frame corner, one can easily determine if the corner is perfectly square or if adjustments need to be made. Therefore, a steel square is a reliable tool for checking the squareness of a window frame corner.

- Q:How do you use a steel square to determine the angle of a rip cut?

- In order to determine the angle of a rip cut using a steel square, you must follow these steps: 1. First, position the steel square against the edge of the board you wish to cut, ensuring it is flush and square. 2. Then, locate the degrees or angles scale on the outer edge of the steel square. 3. Align the scale with the edge of the board, ensuring that the square blade is perpendicular to the board's edge. 4. Once the square is properly aligned, identify the numerical mark on the scale that represents the desired cutting angle (e.g., 45 degrees). 5. After identifying the correct angle, mark the board along the blade of the steel square, indicating where the cut should be made. 6. Finally, utilize a saw or another cutting tool to follow the marked line and execute the rip cut at the desired angle. Always double-check your measurements and ensure proper alignment of the steel square before making any cuts. By employing a steel square, you can achieve precise and accurate rip cuts by relying on a dependable angle reference.

- Q:Can a steel square be used for pergola post layout and installation?

- Indeed, the utilization of a steel square in the layout and installation of pergola posts is possible. Commonly referred to as a framing square or carpenter's square, a steel square serves as a versatile instrument extensively employed in construction and woodworking ventures. Boasting a 90-degree angle and a lengthier leg, it enables the measurement and marking of straight lines, while the shorter leg facilitates angle marking and the creation of perpendicular lines. In regards to pergola post layout and installation, a steel square proves invaluable in guaranteeing precise and accurate measurements for post placement and alignment. By employing the square's 90-degree angle, one can establish perpendicular lines and corners, allowing for appropriate post spacing. Additionally, the longer leg of the square serves to measure and mark the desired distance for each post, ensuring uniformity and symmetry in the pergola's structure. Furthermore, the steel square can also verify the levelness and plumb of the posts during installation. By positioning the square against the post sides, it becomes an aid in ensuring perfect verticality and alignment. This aspect is critical for the pergola's stability and overall structural integrity. Ultimately, a steel square constitutes an invaluable tool for pergola post layout and installation. Its versatility and precision render it an indispensable instrument for both DIY enthusiasts and professional builders undertaking pergola projects.

- Q:How do you use a steel square to determine the angle of a drum sanding cut?

- In order to determine the angle of a drum sanding cut using a steel square, the following steps should be followed: 1. Begin by placing the steel square on a flat surface, making sure it is perpendicular to the table or workbench edge. 2. Position the drum sander on the table, aligning it with the steel square's edge. 3. Rotate the drum sander to adjust the angle until it becomes parallel to one of the steel square's edges. 4. With a protractor or an angle measuring tool, measure the angle between the steel square and the drum sander. 5. Make a note of the angle measurement, as it will be the angle required for the desired cut. 6. Utilize the angle measurement to adjust the drum sander accordingly, either by modifying the table tilt or using any angle adjustment features available on the specific drum sander model. 7. Validate the angle by placing the steel square back on the table and aligning it with the drum sander, ensuring that the drum sander remains parallel to the steel square's edge. 8. Once confident that the drum sander is set at the desired angle, proceed with the drum sanding cut. It is important to acknowledge that using a steel square for determining the angle of a drum sanding cut provides an approximate estimation and may not be as precise as utilizing specialized angle measuring tools. Nevertheless, it can still be a valuable technique for achieving reasonably accurate outcomes in numerous woodworking tasks.

- Q:Can a steel square be used for checking the squareness of a wall frame?

- Checking the squareness of a wall frame is possible with the use of a steel square. A steel square, also known as a framing square, is a tool commonly employed by carpenters and builders to lay out and verify right angles. It comprises two arms, one of which is shorter than the other, creating a 90-degree angle. To verify the squareness of a wall frame, one can position the shorter arm of the steel square against one corner of the frame and the longer arm against the adjacent corner. By observing the alignment of the longer arm with the edges of the frame, it is possible to determine whether the corners are perfectly square or if adjustments are necessary. The steel square offers a precise and dependable method for assessing squareness due to its design, which ensures a consistent 90-degree angle. However, it is important to acknowledge that other factors, such as the quality of the frame's construction and the stability of the wall, can also impact squareness. Therefore, it is advisable to utilize the steel square as an initial step in checking squareness and to perform additional measurements and adjustments as required.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

12mm*1.13kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords