1100 1050 2024 3003 5052 6061 6082 7021 Alloy 5052 Alloy Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Information:

1.Alloy: 1100 1050 2024 2017 3003 5052 6061 6063 7075 7021 etc

2.Temper:O H112 H12 H14 H16 T3 T4 T6 T651 etc

3.Dimension based on customer requirements

4.Good quality choose us

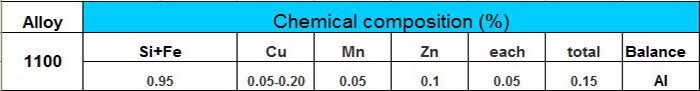

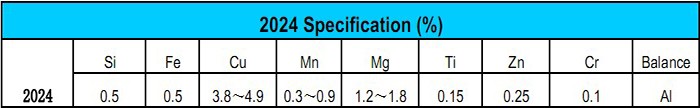

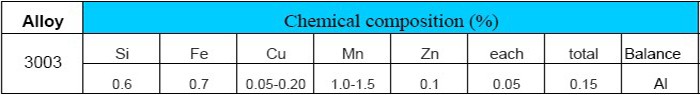

Chemical Composition:

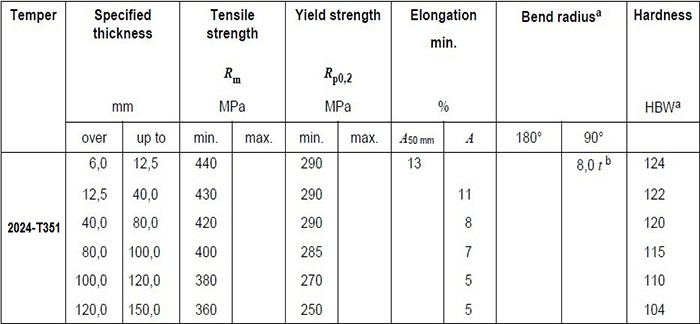

Technical Specification:

Packaging & Delivery

| Packaging Details: | Wooden Pallet, Wooden Case, As Customzed, etc. |

| Delivery Detail: | 15 to 25 days depends on actual order |

Our Services

1) Reply within 12 hours

2) Free samples provided

3) On-site production following-up

4) Loading inspection with container fixing

5)Third party inspection at your request

Company Information

Advanced equipment and strict management both contribute to the excellent quality of products. Our main products are all kinds of cold rolling and hot rolling aluminum sheet, coil, checkered plate, embossed plate, aluminum foil, aluminum disc, aluminum profile, painted aluminum sheet and coil. Our products have various size choices with thickness from 0.008mm to 350mm, width from 200mm to 2300mm and length below 12m. Our products are sold to all over the world, including South America, North America, Europe, Middle-East, South-East Asia, Africa etc and used in various fields such as construction, decoration, automobile, electronic, machinery, boat construction, aeronautics&astronautics, cookware, packing etc.

Adhering to the principle of “ Surviving with quality and developing with credibility”, CNBM hopes to work with all customers for a better future.

FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 5 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

4) Why YONGHONG?

With us, you get most competitive price, guranteened quality with assured delivery time and after sales service

- Q:How do aluminum sheets perform in terms of electrical insulation?

- Aluminum sheets have poor electrical insulation properties as they are highly conductive materials.

- Q:What is the typical impact strength of aluminum sheets?

- The typical impact strength of aluminum sheets can vary depending on the alloy and temper of the material. However, in general, aluminum sheets have a relatively low impact strength compared to other metals. This is because aluminum is a lightweight material that is not as strong or durable as steel or other alloys. The impact strength of aluminum sheets is typically measured in terms of the energy required to cause the material to fracture or deform. This can be expressed in units such as joules or foot-pounds. While specific values may vary, aluminum sheets generally have an impact strength ranging from 10 to 40 joules or 7 to 30 foot-pounds. It is important to note that the impact strength can be influenced by factors such as thickness, surface condition, and the presence of any surface treatments or coatings. Therefore, it is recommended to consult the manufacturer's specifications or conduct specific tests to determine the impact strength of a particular aluminum sheet.

- Q:Can aluminum sheet be used for automotive body-in-white applications?

- Yes, aluminum sheet can be used for automotive body-in-white applications. Aluminum's lightweight yet strong properties make it an ideal material for constructing vehicle bodies, providing improved fuel efficiency and overall performance.

- Q:I need to find 3 elements for my science hw tonight. I was wondering if aluminum foil is a pure element. And also I was wondering if anyone had any ideas of what is a pure element (not a compound or an alloy). Thanks!!!!

- I'm pretty sure that the words element and pure element are exchangeable... pure element basically just emphasizes the fact that it is pure.

- Q:Can aluminum sheets be laser engraved?

- Yes, aluminum sheets can be laser engraved. Laser engraving is a versatile and precise method of marking or engraving various materials, including metals like aluminum. The process involves using a high-powered laser beam to remove the top layer of the aluminum sheet, creating a permanent and precise engraving. Laser engraving on aluminum sheets is commonly used in industries such as signage, jewelry, and industrial manufacturing for applications such as branding, product identification, and decorative purposes. The level of detail and resolution achievable through laser engraving on aluminum sheets depends on the power and settings of the laser machine used.

- Q:iron-based alloys over aluminum in structural members of bridges and buildings?

- Because it's lighter with about the same strength as iron alloys

- Q:Can the aluminum sheets be used for manufacturing electrical connectors?

- Indeed, electrical connectors can be manufactured using aluminum sheets. The lightweight and exceptional conductivity of aluminum render it ideal for the efficient transmission of electricity. Its outstanding conductivity and ability to resist corrosion make it a frequently employed material in diverse electrical applications, particularly connectors. Furthermore, the malleability and ease with which aluminum can be molded into diverse connector designs make it an adaptable material for the production of electrical connectors.

- Q:What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is generally considered to be excellent. Aluminum is a highly malleable metal, meaning it can be easily shaped or formed into various designs without cracking or breaking. This characteristic makes aluminum sheets highly desirable for a wide range of applications, including automotive body panels, aircraft components, and household appliances. Additionally, aluminum has good ductility, which allows it to be stretched and bent without losing its structural integrity. However, it is important to note that the formability of aluminum sheets can vary depending on the alloy composition, thickness, and processing conditions. Therefore, it is essential to consider these factors when choosing the appropriate aluminum sheet for a specific application.

- Q:why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q:Are aluminum sheets affected by UV radiation or sunlight exposure?

- UV radiation and sunlight can indeed have an impact on aluminum sheets. With the passage of time, the sheets may undergo oxidation due to their exposure to UV radiation and sunlight, resulting in an unsightly and lackluster appearance. Furthermore, extended exposure to UV rays can lead to material weakening, rendering it susceptible to cracking or breakage. To safeguard aluminum sheets from the detrimental consequences of UV radiation, it is advisable to employ a protective coating or opt for anodized aluminum, which boasts a sturdier and longer-lasting surface.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1100 1050 2024 3003 5052 6061 6082 7021 Alloy 5052 Alloy Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords