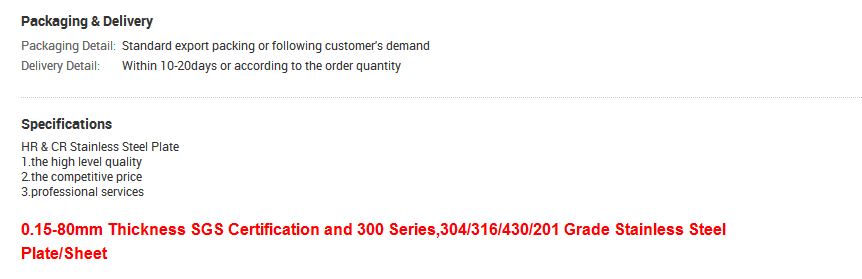

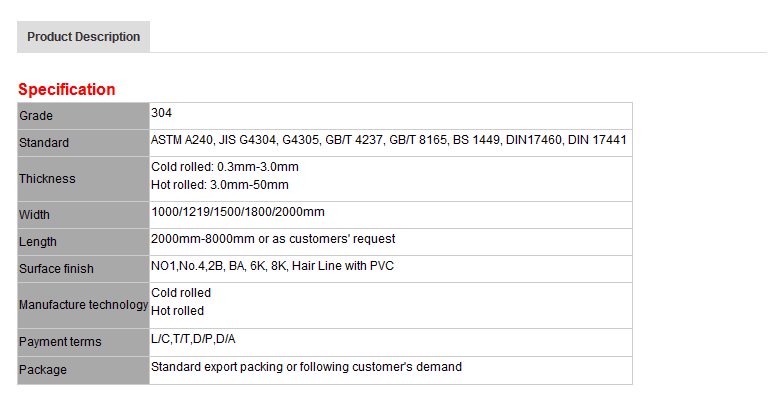

0.15-80mm Thickness SGS Certification and 300 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What's the difference between stainless steel pipe and stainless steel composite pipe?

- Stainless steel is also divided into several kinds of 200201300301304,The market is generally 301 material, 304 of the best results, followed by 301.

- Q:What are the connecting methods of stainless steel pipes for indoor water pipes?

- Card type features: easy to install, connecting the external pipe, the internal rubber ring is evenly compressed into hexagonal. Scope of application: cold water system, pipe direct drinking water system, and more suitable for pipe installation. The utility model has the advantages that the connection is simple and convenient, the working hours are short, and the cost is moderate. Drawback is the single application, the maintenance of trouble, both the pipe sealing ring in aging and need to be replaced more trouble, because the connection was stuck, replacement is the need to both ends of the pipe to replace the sawing.

- Q:What is the difference between 304Cb and 316Cb stainless steel pipes?

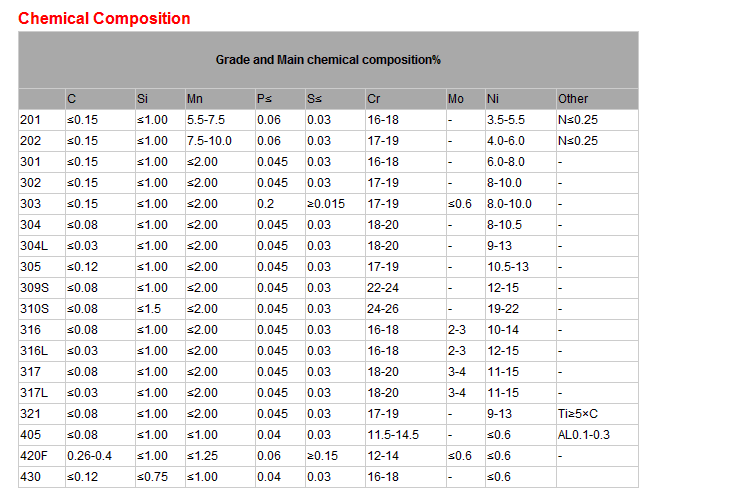

- The main difference between 304Cb and 316Cb stainless steel pipes lies in their chemical composition and their respective properties. 304Cb stainless steel is an austenitic stainless steel alloy that contains chromium and nickel. It also has a small amount of niobium, which enhances its resistance to intergranular corrosion. This makes 304Cb stainless steel pipes suitable for a wide range of applications, including food processing, chemical and petrochemical industries, and architectural purposes. On the other hand, 316Cb stainless steel is also an austenitic stainless steel alloy that contains chromium and nickel. However, it has a higher percentage of molybdenum, which gives it superior resistance to corrosion and pitting in chloride environments. This makes 316Cb stainless steel pipes ideal for applications where exposure to saltwater or other corrosive substances is common, such as marine environments or coastal areas. In summary, while both 304Cb and 316Cb stainless steel pipes are excellent choices for various applications, 316Cb stainless steel offers better corrosion resistance in chloride environments due to its higher molybdenum content. Depending on the specific needs and environment of the application, one may be more suitable than the other.

- Q:What is the difference between 316 and 316LN stainless steel pipes?

- 316 and 316LN stainless steel pipes are both variations of the same grade of stainless steel, which is known as 316. However, there are some differences between the two. The main difference between 316 and 316LN stainless steel pipes lies in their nitrogen content. 316LN stainless steel contains a higher amount of nitrogen compared to 316 stainless steel. The addition of nitrogen improves the strength and corrosion resistance of the material, making it more suitable for certain applications. Due to its increased nitrogen content, 316LN stainless steel pipes exhibit improved resistance to pitting and crevice corrosion, especially in chloride environments. This makes them particularly suitable for use in marine environments or other applications where the pipes may come into contact with corrosive substances. Another difference between the two grades is their availability and cost. 316 stainless steel pipes are more widely available and commonly used, making them generally more cost-effective compared to 316LN stainless steel pipes. However, 316LN stainless steel pipes may be required for specific applications where enhanced corrosion resistance is necessary. In summary, the main difference between 316 and 316LN stainless steel pipes lies in their nitrogen content, which affects their corrosion resistance properties. While 316 stainless steel is more widely available and cost-effective, 316LN stainless steel offers improved resistance to pitting and crevice corrosion, making it suitable for certain applications.

- Q:Can stainless steel pipes be used in the food processing industry?

- The food processing industry can make use of stainless steel pipes. Stainless steel is a preferred option in food processing because it possesses numerous advantageous qualities. Firstly, stainless steel's resistance to corrosion is vital in an environment where food and liquids are constantly being handled and processed. Additionally, stainless steel's easy maintenance and cleaning are crucial for ensuring hygiene and preventing contamination in food processing. Stainless steel pipes are also highly durable and strong, enabling them to withstand the demanding conditions of the food processing industry. Furthermore, stainless steel does not react chemically with food or ingredients, ensuring that the quality and taste of processed products remain unaffected. Overall, stainless steel pipes are an exceptional choice for the food processing industry due to their resistance to corrosion, cleanliness, durability, and non-reactive properties.

- Q:Can stainless steel pipes be used for geothermal heating systems?

- Yes, stainless steel pipes can be used for geothermal heating systems. Stainless steel is highly resistant to corrosion, making it suitable for the harsh underground environment of geothermal systems. It also has excellent thermal conductivity, allowing for efficient heat transfer.

- Q:How thick is the 3 stainless steel tube?

- Refers to the stainless steel tube with a wall thickness of 3 mm.

- Q:Are stainless steel pipes suitable for brewing systems?

- Yes, stainless steel pipes are highly suitable for brewing systems. Stainless steel is the preferred material for brewing equipment due to its excellent corrosion resistance, hygienic properties, and durability. Stainless steel pipes do not react with the acidic components present in brewing, ensuring that there are no unwanted flavors or contaminants introduced into the beer. Additionally, stainless steel pipes are easy to clean and maintain, making them ideal for the brewing process. Overall, stainless steel pipes provide a reliable and long-lasting solution for brewing systems, ensuring the production of high-quality and uncontaminated beer.

- Q:Are stainless steel pipes suitable for power plants?

- Yes, stainless steel pipes are highly suitable for power plants. They offer exceptional resistance to corrosion, high temperatures, and pressure, making them ideal for transporting various fluids and gases within power plants. Additionally, stainless steel pipes have excellent strength and durability, ensuring long-term reliability in the demanding operating conditions of power plants.

- Q:What are the common corrosion issues with stainless steel pipes?

- There are a few common corrosion issues that can occur with stainless steel pipes. One of the most common is called pitting corrosion, which is characterized by small pits or holes that form on the surface of the pipe. Pitting corrosion is often caused by exposure to chloride ions, which can come from substances like saltwater or certain types of cleaning agents. Another common corrosion issue is crevice corrosion, which occurs in the narrow gaps or crevices between the pipe and other surfaces. These gaps can trap moisture or other corrosive substances, leading to localized corrosion. Crevice corrosion is often seen in areas where the pipe is joined or in areas with poor ventilation. Stress corrosion cracking is another common problem with stainless steel pipes. It occurs when the material is exposed to a combination of tensile stress and a corrosive environment. This can cause cracks to develop in the pipe, which can lead to leaks or structural failure. Finally, galvanic corrosion is a common issue when stainless steel pipes are in contact with other metals. When two different types of metals are in contact in the presence of an electrolyte, such as water, a galvanic cell can form and cause corrosion. To prevent this, it is important to use appropriate insulation or isolation techniques when connecting stainless steel pipes to other metals. Overall, while stainless steel is known for its corrosion resistance, it is not completely immune to corrosion. Understanding these common corrosion issues and taking preventive measures can help ensure the longevity and reliability of stainless steel pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

0.15-80mm Thickness SGS Certification and 300 Series

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords