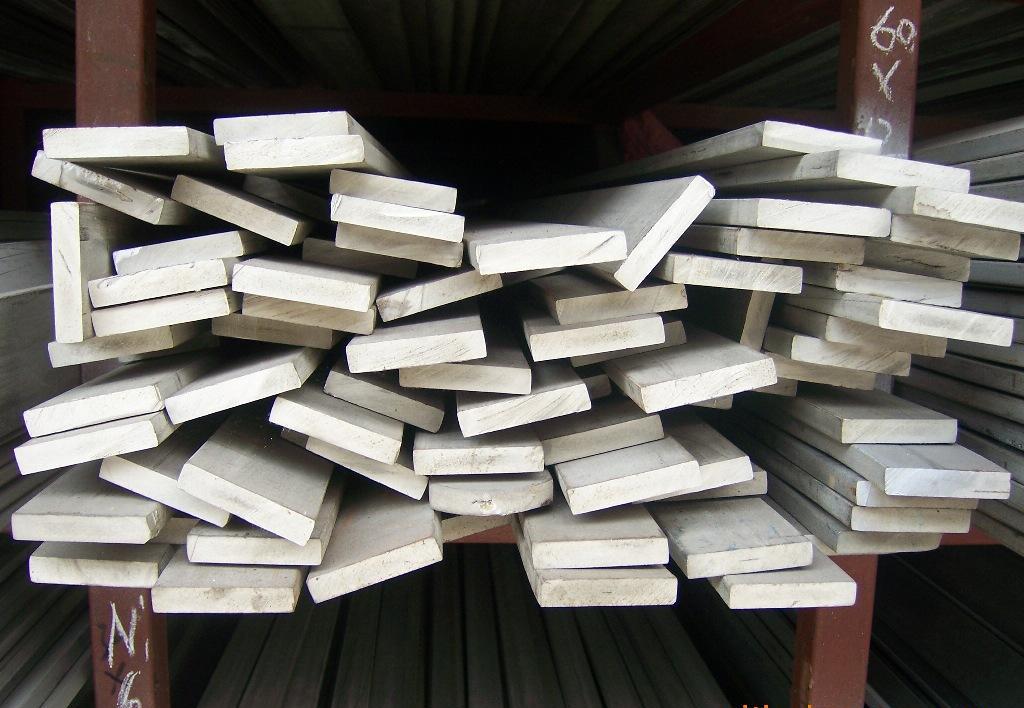

316L Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Flats

1. Standard: AISI, GB, JIS, ASTM, DIN, EN

2. Grade: 1).200Series: 201,202.

2).300Series: 301,302,303,304,304L,316,316L,321.

3).400Series: 410,410S,416,420,430,430F.

3. Size:3x25mm- 80x250mm

4. Length: 2m-6m

5. Craft: HRAP, or cold drawn

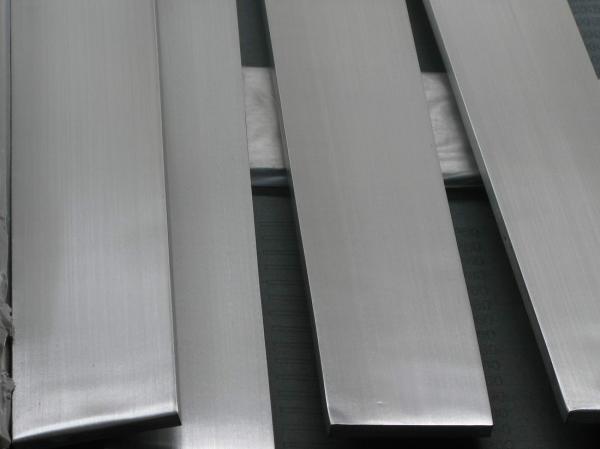

6. Stainless Steel Flat Bar Surface: Pickling or polished

7. MOQ: 1000kg

8. Delivery: within 20 days

9. Package: Waterproof with tape

10. Application: These products are widely supplied to areas of machine-made industry, chemical industry, shipping industry,architecture, food industry, household products etc.

|

Name |

Stainless Steel Flat Bar | ||||||||

|

Material |

201.202.301.304.304L,304N,304LN, 309S,310S,316,316L, 316Ti,316N,316LN,317,317L,347, 347H,etc. | ||||||||

|

Standard |

JIS/AISI/ ASTM,/GB,/DIN,/EN/SUS.etc. | ||||||||

Shape |

Stainless steel Round/flat/square/angle/hexagonal bar | ||||||||

Price term |

FOB/CIF/CNF or as required | ||||||||

|

Length |

6m,5.8m,4m as required | ||||||||

|

Application |

kitchen and sanitary wares , and Structural use high strength components,furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc | ||||||||

|

Payment terms |

L/C,T/T,Western Union,or as required. | ||||||||

|

MOQ |

As required | ||||||||

|

Packing |

Export standard package | ||||||||

|

Certificate |

ISO/SGS | ||||||||

|

Contact |

If you are interested in our products,please feel free to contact me. Cherryliu@okorder.com |

- Q:What is the internal roughness of stainless steel pipes?

- The internal roughness of stainless steel pipes refers to the texture or unevenness on the inner surface of the pipes, which can affect the flow of fluids or gases through the pipes. It is typically measured in terms of roughness coefficients or Ra values, indicating the average height of irregularities on the pipe's interior.

- Q:Can stainless steel pipes be laser welded?

- Yes, stainless steel pipes can be laser welded.

- Q:What are the weld sleeves for stainless steel pipes?

- The process is the same as you set for the pipe welding material quota, stainless steel drop can, on the line in the budget when a show

- Q:How do you calculate the required support spacing for stainless steel pipes?

- Several factors must be taken into account when calculating the necessary support spacing for stainless steel pipes. These factors encompass the pipe diameter, the weight of the material, the system's temperature, the fluid flowing through the pipe, and the desired safety factor. The initial step involves determining the pipe diameter. This can be achieved by direct measurement or by calculating it using the pipe's schedule and nominal size. Once the diameter is known, the weight of the stainless steel pipe per unit length can be determined using the density of stainless steel. Afterwards, the temperature of the system in which the pipe will operate must be considered. Stainless steel pipes can expand and contract with temperature changes, and this thermal expansion must be taken into account when determining support spacing. The thermal expansion coefficient of stainless steel can be utilized to calculate the expected expansion across the temperature range. The fluid flowing through the pipe should also be taken into consideration. If the fluid is corrosive or possesses high velocity or pressure, additional supports may be necessary to prevent excessive vibration or stress on the pipe. Finally, the desired safety factor must be incorporated. This factor represents the additional support spacing required to ensure the integrity and stability of the pipe system. Common safety factors typically range from 1.5 to 3, depending on the specific application and industry standards. Once all these factors are known, various industry standards and guidelines can be employed to calculate the required support spacing for stainless steel pipes. These standards provide formulas and tables that consider the aforementioned factors, enabling engineers and designers to determine the appropriate distance between pipe supports. It is important to note that qualified professionals with knowledge of industry standards and local regulations should perform these calculations to ensure the safe and efficient operation of the stainless steel pipe system.

- Q:What are the different types of stainless steel pipe flanges?

- There are several different types of stainless steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, and lap joint flanges. Each type has its own unique design and application, making them suitable for various piping systems and industries.

- Q:Can stainless steel pipes be chrome plated?

- Yes, stainless steel pipes can be chrome plated. Chrome plating is a process that involves electroplating a thin layer of chromium onto the surface of the stainless steel pipe. This can give the pipe a shiny and reflective appearance, as well as provide added protection against corrosion. However, it is important to note that the stainless steel pipe must be properly prepared and cleaned before the chrome plating process can be carried out. Additionally, the chrome plating process should be performed by a professional or a specialized company with experience in chrome plating.

- Q:What is the difference between 904L and 2205 stainless steel pipes?

- 904L and 2205 are both types of stainless steel pipes, but they have some key differences. Firstly, the composition of the two steels is different. 904L stainless steel is a high alloy austenitic stainless steel that contains high levels of chromium, nickel, and molybdenum. It also has low carbon content, making it highly resistant to corrosion and pitting. On the other hand, 2205 stainless steel is a duplex stainless steel that consists of a mixture of austenite and ferrite phases. It contains lower levels of chromium and nickel compared to 904L, but has higher levels of molybdenum and nitrogen. Secondly, the mechanical properties of the two steels differ. 904L stainless steel has excellent toughness and high strength, making it suitable for applications in aggressive environments such as chemical processing plants and offshore oil and gas platforms. In contrast, 2205 stainless steel has good overall mechanical properties, with high tensile and yield strength. It is commonly used in industries such as marine, paper, and pulp, where resistance to stress corrosion cracking is important. Another difference lies in their resistance to corrosion. While both steels are corrosion-resistant, 904L stainless steel has exceptional resistance to a wide range of corrosive environments, including sulfuric acid, hydrochloric acid, and saltwater. This makes it ideal for use in industries where extreme corrosion resistance is required. 2205 stainless steel, although not as corrosion-resistant as 904L, still offers good resistance to many corrosive substances, making it suitable for various applications. Cost is another factor that sets these steels apart. Due to its high alloy content and superior properties, 904L stainless steel is generally more expensive than 2205 stainless steel. Therefore, the choice between the two will depend on the specific requirements of the application and the budget. In summary, the main differences between 904L and 2205 stainless steel pipes lie in their composition, mechanical properties, corrosion resistance, and cost. Understanding these distinctions will help in selecting the appropriate stainless steel pipe for a given application.

- Q:Are stainless steel pipes suitable for power generation plants?

- Yes, stainless steel pipes are suitable for power generation plants. Stainless steel is known for its excellent corrosion resistance, which makes it ideal for use in power generation plants that involve high temperatures, pressure, and corrosive environments. Power generation plants often use various types of fluids, such as steam, water, and chemicals, which can cause corrosion and degradation of the piping system. Stainless steel pipes can withstand these harsh conditions and provide long-lasting performance. Furthermore, stainless steel pipes have high strength and durability, which is crucial for power generation plants that operate at high pressures. They can handle the stress and strain of the system without the risk of failure or leakage. In addition, stainless steel is also resistant to scaling and fouling, which is important for maintaining the efficiency of the power plant. The smooth internal surface of stainless steel pipes helps to minimize friction and pressure losses, ensuring efficient flow of fluids. Moreover, stainless steel pipes are easy to maintain and clean. They do not require frequent inspections or repairs, reducing downtime and maintenance costs for power generation plants. Overall, the superior corrosion resistance, strength, durability, and efficiency of stainless steel pipes make them highly suitable for power generation plants. They offer a reliable and long-lasting solution for fluid conveyance in such demanding environments.

- Q:How much more expensive is 304 stainless steel than 201?

- 201 in the stainless steel industry, represents a kind of material, 201 stainless steel is generally refers to 201 stainless steel and acid resistant steel floorboard. 201 stainless steel refers to the atmosphere, steam, water and other weak medium corrosion of steel, while acid resistant steel refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel.

- Q:Advantages and disadvantages of PPR lined stainless steel pipe and PPR aluminium plastic pipe

- PPR lined stainless steel tubeAdvantage:Stainless steel lining pipe, high temperature resistance, can transport hot water, boiling water, steam, and safety and health. The installation of stainless steel tube after the whole bearing pipe resistance, impact resistance, corrosion resistance and other properties to strengthen and enhance the original tube, not only can be used for civilian water and gas, can also be used for fluid transportation industry.shortcomingOnce the processing is not well controlled, it is easy to cause stainless steel and PPR delamination.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2010 |

| Annual Output Value | above US$3 million |

| Main Markets | East Asia, Middle East. |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 50% |

| No.of Employees in Trade Department | above 10 people |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | about 50000 square meter |

| No. of Production Lines | above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

316L Stainless Steel Flat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords