All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

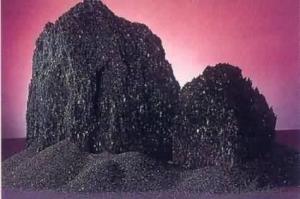

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How does the particle size distribution of raw materials impact refractory properties?

The particle size distribution of raw materials plays a crucial role in determining the refractory properties. It affects the packing density, permeability, and sintering behavior of the refractory material. Smaller particle sizes tend to increase the packing density, leading to improved mechanical strength and reduced porosity. However, an excessive amount of fine particles can hinder sintering, resulting in weaker refractory properties. On the other hand, larger particle sizes can enhance permeability but may lead to reduced packing density. Therefore, achieving an optimal particle size distribution is essential in designing refractory materials with desired properties.

What are the benefits of using corundum as a raw material in refractory production?

Corundum offers several benefits when used as a raw material in refractory production. It has a high melting point and excellent thermal stability, which makes it resistant to extreme temperatures and thermal shocks. Corundum also has good chemical stability, making it resistant to corrosion from various chemicals and gases. Additionally, it has high hardness and abrasion resistance, ensuring durability and long-lasting performance in harsh environments. These properties make corundum an ideal choice for refractory production, providing reliable insulation and protection in industries such as steel, cement, and glass.

How do raw materials impact the resistance to slag attack of refractory products?

Raw materials play a crucial role in determining the resistance to slag attack of refractory products. The type and quality of raw materials used directly influence the chemical composition, physical properties, and structural integrity of the refractory product. Certain raw materials, such as high alumina content, can enhance the resistance to slag attack due to their ability to form protective layers and reduce the reactivity with slag. On the other hand, the presence of impurities or low-quality raw materials can lead to increased slag penetration and deterioration of the refractory product. Therefore, the selection and proper utilization of raw materials are essential in ensuring the desired resistance to slag attack in refractory products.

Can you explain the role of wollastonite in refractory materials?

Wollastonite plays a crucial role in refractory materials as a mineral additive. It provides several benefits, including improved strength, thermal stability, and resistance to thermal shock. Wollastonite also acts as a fluxing agent, reducing the melting point of the refractory material and enhancing its ability to withstand high temperatures. Additionally, its low thermal expansion coefficient helps prevent cracking and damage caused by rapid temperature changes. Overall, wollastonite enhances the performance and durability of refractory materials, making them more suitable for applications in high-temperature environments.

Wholesale Raw Materials For Refractory from supplier in Belgium

We are a Raw Materials For Refractory supplier serving the Belgium, mainly engaged in the sale, quotation, and technical support services of various Raw Materials For Refractory products in the Belgium region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Raw Materials For Refractory procurement services in the Belgium. Not only do we have a wide range of Raw Materials For Refractory products, but after years of market development in the Belgium, we can also provide valuable experience for your projects.

Hot Search

- Monolithic Refractories in Czech Republic

- Ceramic Fiber Products in Dominica

- Refractory Bricks in Senegal

- Raw Materials For Refractory in Bulgaria

- Refractory Bricks in Gabon

- Monolithic Refractories in Tunisia

- Monolithic Refractories in Spain

- Raw Materials For Refractory in Palestine

- Ceramic Fiber Products in Argentina

- Refractory Bricks in South Africa