All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

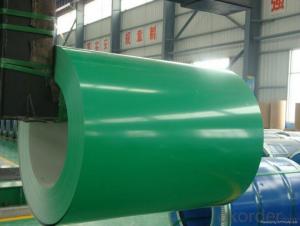

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the benefits of employing pre-painted steel coils in construction projects?

There are several benefits of employing pre-painted steel coils in construction projects. Firstly, pre-painted steel coils offer a durable and long-lasting solution, as the paint acts as a protective layer against corrosion and other environmental factors. This helps to extend the lifespan of the construction, reducing maintenance and replacement costs. Additionally, pre-painted steel coils provide a wide range of color options, allowing for greater design flexibility and aesthetic appeal in construction projects. Moreover, the use of pre-painted steel coils helps to expedite the construction process, as the material arrives already painted and ready for installation, saving both time and labor costs. Overall, employing pre-painted steel coils in construction projects offers enhanced durability, design flexibility, and efficiency, making it a favorable choice for builders and developers.

How do steel coil properties vary when used in the renewable energy sector for solar panel frames and wind turbines?

Steel coil properties can vary in the renewable energy sector for solar panel frames and wind turbines based on the specific requirements of each application. For solar panel frames, steel coils with high strength and corrosion resistance are preferred to withstand outdoor conditions and provide structural support. In wind turbines, steel coils with excellent fatigue resistance and high tensile strength are crucial to withstand the cyclic loading and stress caused by wind gusts. Additionally, the thickness and coating of the steel coils may differ for each application to ensure optimal performance and longevity in the renewable energy sector.

What is the impact of coil temperature on the performance of stamping and forming processes?

The impact of coil temperature on the performance of stamping and forming processes is significant. Higher coil temperatures can lead to increased material ductility, making it easier to shape and form the metal. This can result in improved formability, reduced springback, and enhanced part quality. Conversely, lower coil temperatures can make the material less ductile, leading to increased cracking or tearing during the stamping or forming process. Therefore, maintaining the appropriate coil temperature is crucial for achieving optimal performance in these manufacturing processes.

How is steel prepared for coil production?

Steel is prepared for coil production by undergoing a series of processes including cleaning, heating, rolling, and cooling. The steel is first cleaned to remove any impurities, then heated to its optimal temperature for rolling. It is then passed through rolling mills multiple times to reduce its thickness and shape it into a coil. Finally, the coil is cooled and either stored or further processed for various applications.

Wholesale Steel Coils from supplier in Belgium

We understand the importance of delivering high-quality products and excellent customer service. Our team consists of industry experts who are well-versed in the latest trends and technologies in the steel industry. This enables us to offer reliable technical support and guidance to our customers, ensuring that they make informed decisions for their projects.

As a reliable supplier, we maintain strong relationships with reputable manufacturers, ensuring that our steel coils meet international quality standards. Our product range includes hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, and stainless steel coils, among others. We can also provide customized solutions to suit specific project requirements.

In addition to our product offerings, we also offer competitive pricing and flexible delivery options to meet our customers' needs. With our efficient logistics network, we can ensure timely delivery of orders to any location in Belgium.

Whether you are involved in construction, automotive, manufacturing, or any other industry that requires steel coils, our company is committed to meeting your needs. Contact us today for sales, quotations, and technical support services for steel coils in Belgium.

As a reliable supplier, we maintain strong relationships with reputable manufacturers, ensuring that our steel coils meet international quality standards. Our product range includes hot-rolled steel coils, cold-rolled steel coils, galvanized steel coils, and stainless steel coils, among others. We can also provide customized solutions to suit specific project requirements.

In addition to our product offerings, we also offer competitive pricing and flexible delivery options to meet our customers' needs. With our efficient logistics network, we can ensure timely delivery of orders to any location in Belgium.

Whether you are involved in construction, automotive, manufacturing, or any other industry that requires steel coils, our company is committed to meeting your needs. Contact us today for sales, quotations, and technical support services for steel coils in Belgium.