All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

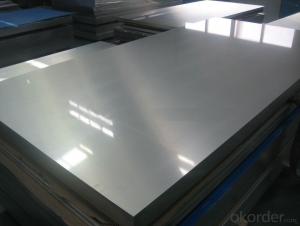

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does stainless steel plate perform in extreme weather conditions?

Stainless steel plate performs exceptionally well in extreme weather conditions due to its high corrosion resistance, durability, and strength. It remains unaffected by rain, snow, heat, and cold, making it ideal for outdoor applications. Additionally, it retains its structural integrity, preventing deformation or cracking even under extreme temperature fluctuations. Its ability to withstand harsh weather conditions without deteriorating or compromising its performance makes stainless steel plate a reliable choice in various industries.

How is stainless steel plate manufactured?

Stainless steel plate is manufactured through a multi-step process that involves melting, casting, hot rolling, cold rolling, and finishing. Initially, raw materials such as iron ore, nickel, chromium, and other alloying elements are melted in a furnace to create molten steel. This molten steel is then continuously cast into large slabs using a casting machine. The slabs are then heated and hot rolled to reduce their thickness and increase their length. After the hot rolling process, the plates undergo a cold rolling process to further refine their dimensions and improve their surface finish. Finally, the stainless steel plates are subjected to various finishing processes such as pickling, annealing, and descaling to remove any impurities and enhance their corrosion resistance properties.

How do you texture and emboss stainless steel plates for aesthetic purposes?

To texture and emboss stainless steel plates for aesthetic purposes, various techniques can be employed. One common method involves using specialized tools like hammers, chisels, or punches to create patterns or textures on the surface of the stainless steel. These tools can be used to gently strike or press the steel, creating embossed designs or raised patterns. Another technique involves using acid etching, where a chemical solution is applied to the stainless steel, selectively removing layers of the metal to create the desired texture or design. Additionally, laser engraving or CNC machining can be utilized to etch precise and intricate patterns onto the stainless steel surface. Each method provides unique results, allowing individuals to achieve their desired aesthetic effects on stainless steel plates.

Wholesale Stainless Steel Plate from supplier in Belgium

We are a Stainless Steel Plate supplier serving the Belgium, mainly engaged in the sale, quotation, and technical support services of various Stainless Steel Plate products in the Belgium region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Stainless Steel Plate procurement services in the Belgium. Not only do we have a wide range of Stainless Steel Plate products, but after years of market development in the Belgium, we can also provide valuable experience for your projects.