All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

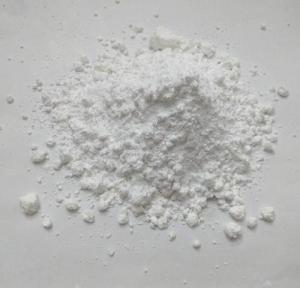

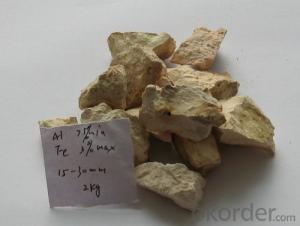

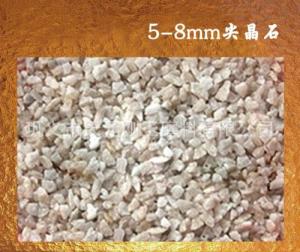

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the common thermal insulation materials employed in refractory applications?

The common thermal insulation materials employed in refractory applications include ceramic fibers, calcium silicate, vermiculite, perlite, and expanded polystyrene.

What is the purpose of silica gel in refractory materials?

The purpose of silica gel in refractory materials is to act as a binder or additive, improving the mechanical strength and thermal stability of the material. It helps enhance the overall performance and durability of the refractory, allowing it to withstand high temperatures and thermal shock.

How do raw materials affect the thermal conductivity of refractory products?

Raw materials play a crucial role in determining the thermal conductivity of refractory products. The choice of raw materials, their composition, and physical properties directly influence the ability of refractory products to conduct heat. Materials with high thermal conductivity, such as metals, can enhance heat transfer through the refractory product, resulting in higher thermal conductivity. Conversely, materials with low thermal conductivity, such as insulating fibers or ceramics, can hinder heat transfer and reduce the overall thermal conductivity of the refractory product. Therefore, the selection and combination of raw materials are key factors in controlling the thermal conductivity of refractory products.

How do different types of sepiolite compare in terms of performance in refractory applications?

Different types of sepiolite can vary in terms of their performance in refractory applications. The performance of sepiolite in refractory applications depends on various factors such as its chemical composition, particle size, porosity, and thermal stability. Generally, sepiolite with higher purity and finer particle size tends to exhibit better performance in refractory applications. It can provide improved insulation, heat resistance, and mechanical strength, making it suitable for high-temperature environments. However, it is important to consider specific application requirements and consult with experts to determine the most suitable type of sepiolite for a given refractory application.

Wholesale Raw Materials For Refractory from supplier in Palestine

With our expertise and resources, we are able to offer a wide range of raw materials for refractory applications in Palestine. Whether you need materials for high-temperature furnaces, kilns, or other applications, we have you covered.

Our sales team is dedicated to providing you with the best products at competitive prices. We understand the importance of timely delivery and work closely with our logistics partners to ensure your orders are delivered on time.

In addition to sales, we also provide quotations based on your specific requirements. Our team will work closely with you to understand your needs and provide you with accurate and competitive pricing.

Furthermore, we offer technical support to help you optimize your refractory materials usage. Our team of experts can provide guidance on material selection, installation techniques, and troubleshooting. We are committed to assisting you in achieving the best results for your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a strong and reliable parent company. This enables us to provide you with all-in-one procurement solutions, ensuring a seamless and hassle-free experience.

We have built a strong presence in the Palestine region through years of operation and have gained valuable market experience. We understand the unique requirements and challenges of the local market, allowing us to provide tailored solutions to meet your specific needs.

Choose us as your supplier of raw materials for refractory in Palestine and experience the difference our comprehensive services, quality products, and expert support can make to your projects. Contact us today for more information or to discuss your requirements.

Our sales team is dedicated to providing you with the best products at competitive prices. We understand the importance of timely delivery and work closely with our logistics partners to ensure your orders are delivered on time.

In addition to sales, we also provide quotations based on your specific requirements. Our team will work closely with you to understand your needs and provide you with accurate and competitive pricing.

Furthermore, we offer technical support to help you optimize your refractory materials usage. Our team of experts can provide guidance on material selection, installation techniques, and troubleshooting. We are committed to assisting you in achieving the best results for your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the backing of a strong and reliable parent company. This enables us to provide you with all-in-one procurement solutions, ensuring a seamless and hassle-free experience.

We have built a strong presence in the Palestine region through years of operation and have gained valuable market experience. We understand the unique requirements and challenges of the local market, allowing us to provide tailored solutions to meet your specific needs.

Choose us as your supplier of raw materials for refractory in Palestine and experience the difference our comprehensive services, quality products, and expert support can make to your projects. Contact us today for more information or to discuss your requirements.

Hot Search

- Monolithic Refractories in Bangladesh

- Ceramic Fiber Products in Mongolia

- Refractory Bricks in British

- Raw Materials For Refractory in Italy

- Refractory Bricks in Turkey

- Monolithic Refractories in Malaysia

- Raw Materials For Refractory in Malta

- Ceramic Fiber Products in Philippines

- Raw Materials For Refractory in Kiribati

- Ceramic Fiber Products in Argentina