All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

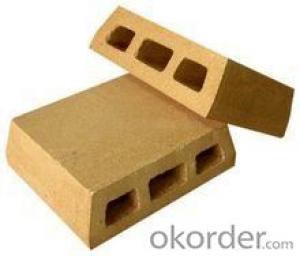

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the common refractory brick shapes used in aluminum production?

The common refractory brick shapes used in aluminum production include straight, arch, wedge, and taper bricks.

Are refractory bricks resistant to hydrochloric acid?

Yes, refractory bricks are generally resistant to hydrochloric acid due to their high temperature stability and chemical inertness.

What are the different refractory brick lining techniques?

There are several different refractory brick lining techniques used in various industries. Some of these techniques include dry stacking, plastic refractory lining, castable refractory lining, and gunning. Dry stacking involves stacking bricks without any mortar, relying on the bricks' shape and interlocking properties for stability. Plastic refractory lining involves shaping a plastic refractory material into the desired lining shape and allowing it to harden. Castable refractory lining involves pouring a refractory mixture into a mold and allowing it to solidify. Gunning is a technique where a refractory mix is sprayed onto a surface using a gunning machine, forming a seamless lining. These techniques are chosen based on factors such as the specific application, desired lining thickness, and the type of refractory material being used.

What are the common refractory brick shapes used in brick kilns?

The common refractory brick shapes used in brick kilns include straight bricks, arch bricks, wedge bricks, and skew bricks.

Wholesale Refractory Bricks from supplier in Palestine

We understand the unique challenges and requirements of the Palestinian market, and we are committed to delivering high-quality Refractory Bricks that meet your specific needs. Whether you require bricks for industrial furnaces, kilns, or any other high-temperature applications, we have the expertise and resources to assist you.

Our team of experienced professionals is dedicated to providing excellent customer service. We will work closely with you to understand your requirements and recommend the most suitable products for your projects. Our sales representatives are always available to answer your queries and provide prompt quotations.

In addition to sales and quotations, we also offer comprehensive technical support. Our experts can provide guidance on installation, maintenance, and troubleshooting to ensure the optimal performance of your refractory bricks. We understand the importance of timely and reliable support, and we are committed to assisting you throughout the entire lifecycle of your projects.

As a subsidiary of CNBM, one of the largest building materials and equipment manufacturers in the world, we have access to a vast network of resources and expertise. This enables us to offer competitive prices, high-quality products, and efficient logistics services. Our strong global presence also allows us to stay updated with the latest industry trends and technologies, ensuring that we can provide you with the most advanced and innovative refractory solutions.

Partnering with us means gaining a reliable and trusted supplier for all your Refractory Bricks requirements in Palestine. We are committed to exceeding your expectations and delivering exceptional value to your projects. Contact us today to discuss your needs and experience the convenience and efficiency of our one-stop procurement services.

Our team of experienced professionals is dedicated to providing excellent customer service. We will work closely with you to understand your requirements and recommend the most suitable products for your projects. Our sales representatives are always available to answer your queries and provide prompt quotations.

In addition to sales and quotations, we also offer comprehensive technical support. Our experts can provide guidance on installation, maintenance, and troubleshooting to ensure the optimal performance of your refractory bricks. We understand the importance of timely and reliable support, and we are committed to assisting you throughout the entire lifecycle of your projects.

As a subsidiary of CNBM, one of the largest building materials and equipment manufacturers in the world, we have access to a vast network of resources and expertise. This enables us to offer competitive prices, high-quality products, and efficient logistics services. Our strong global presence also allows us to stay updated with the latest industry trends and technologies, ensuring that we can provide you with the most advanced and innovative refractory solutions.

Partnering with us means gaining a reliable and trusted supplier for all your Refractory Bricks requirements in Palestine. We are committed to exceeding your expectations and delivering exceptional value to your projects. Contact us today to discuss your needs and experience the convenience and efficiency of our one-stop procurement services.

Hot Search

- Monolithic Refractories in Lesotho

- Ceramic Fiber Products in Uganda

- Refractory Bricks in Niue

- Raw Materials For Refractory in Italy

- Raw Materials For Refractory in Botswana

- Raw Materials For Refractory in Albania

- Refractory Bricks in Ecuador

- Refractory Bricks in Venezuela

- Raw Materials For Refractory in Bhutan

- Monolithic Refractories in Kiribati