PP Woven Geotextile with Excellent Characteristics for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

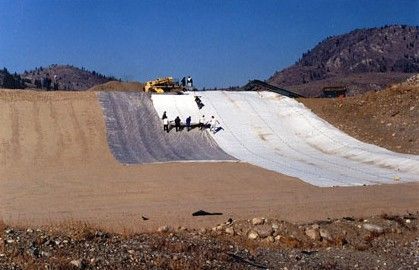

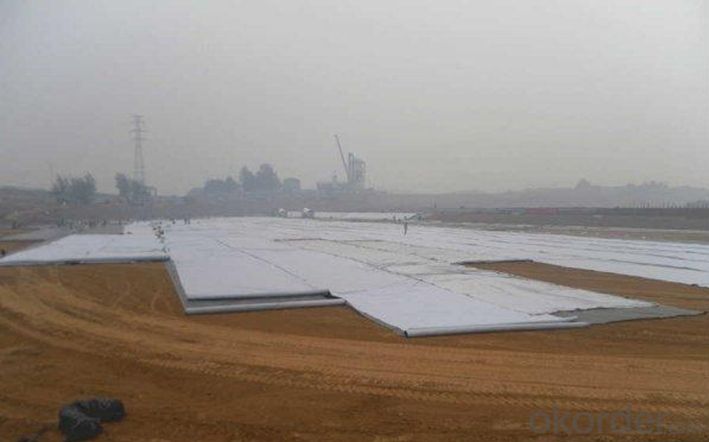

Applications of PP Woven Geotextile for River Construction

Major functions: Separation, filtration, drainage, reinforcement, protection, and liquid barrier

1) Filtration

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3 )Adding muscle

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4 )Protection

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Technical Parameters of PP Woven Geotextile for River Construction

100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | NOTE | |

BASIS WEIGHT TOLERANCE (%) | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

THICKNESS ≥MM | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

TENSILE STRENGTH AT BREAKING ≥KN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | MD&CD |

CBR PLUNGER STRENGTH ≥KN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

TEARING STRENGTH ≥KN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

BREADTH TOLERANCE (%) | -0.5 | |||||||||||

ELONGATION AT BREAKING (%) | 25-100 | MD&CD | ||||||||||

EOS O90mm | 0.07-0.2 | |||||||||||

VERTICAL PERMEABILITY (CM/S) | K×(101~~103) | K=1.0-9.9 | ||||||||||

RFQ:

What is the main application of PP Woven Geotextile for Construction?

The main application of our Short Fiber Nonwoven Geotextile is as follows: The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc.

Where is your main market?

Our main market is in Middle East, South America and some African countries.

What is your advantages for PP Woven Geotextile for Construction?

One of the largest manufacturer of PP Woven Geotextile for Construction

with advanced equipment, big production capacity and excellent quality.

- Q:Geotextile how much money a square

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q:3923.1 why not apply to geotextiles

- Geotextile price, geomembrane price, composite geomembrane price can be found tgcl1123 to see

- Q:What are the limitations of using geotextiles?

- There are several limitations associated with using geotextiles. Firstly, geotextiles may not be as effective in controlling erosion on steep slopes or in areas with heavy rainfall. Additionally, they may not provide adequate support for heavy loads or traffic, making them unsuitable for certain construction projects. Geotextiles also have limited durability and may degrade over time, requiring frequent replacement. Finally, the cost of geotextiles can be relatively high, making them less affordable for some applications.

- Q:Composite geotextile have what model specifications

- Composite geomembrane; mass per unit area g / m000 Membrane thickness mm0.25-0.350.3-0.5 breaking strength KN / m57.510.012.014.016.018.0 vertical and horizontal elongation at break% 30-100CBR breaking strength KN ≥ 1.11 . 51.92.22.52.83.0 Tearing strength KN≥0.150.250.320.40.480.560.62 Vertical and horizontal peel strength N / cm6 Vertical and horizontal permeability coefficient cm / sk * 10-11-10-13k = 1.0-9.9

- Q:What are the common problems encountered during geotextile installation?

- Some common problems encountered during geotextile installation include improper placement or alignment of the geotextile, inadequate anchoring or securing of the material, damage or tears during installation, poor soil preparation, and inadequate or improper selection of geotextile material for the specific application.

- Q:What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects typically include requirements for the material's strength, permeability, filtration properties, and durability. These specifications ensure that the geotextile can effectively separate soil particles from the drainage media, prevent clogging, and maintain its functionality over time. Additionally, the specifications may also address the geotextile's dimensions, weight, and installation guidelines to ensure proper performance in subsurface drainage applications.

- Q:How do geotextiles help with reinforcement of geosynthetic clay liner slopes?

- Geotextiles help with the reinforcement of geosynthetic clay liner slopes by providing additional strength and stability to the slope. They act as a barrier, preventing the clay liner from eroding or sliding down the slope, while also distributing the loads and reducing the risk of soil movement. The geotextiles also enhance the overall performance and longevity of the liner by reducing the impact of external factors such as water flow or vegetation growth.

- Q:Do you have a geotextile bed?

- Well, geotextile material is not environmentally friendly

- Q:How do geotextiles aid in the reduction of settlement-induced cracking?

- Geotextiles aid in the reduction of settlement-induced cracking by providing a stable and reinforced base for construction projects. They distribute the load and enhance the soil's bearing capacity, preventing excessive settlement and subsequent cracking in the structure.

- Q:Is the current tunnel construction, modular waterproof board (geotextile) is available?

- We use the soil is a geotech cloth waterproof board

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PP Woven Geotextile with Excellent Characteristics for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords