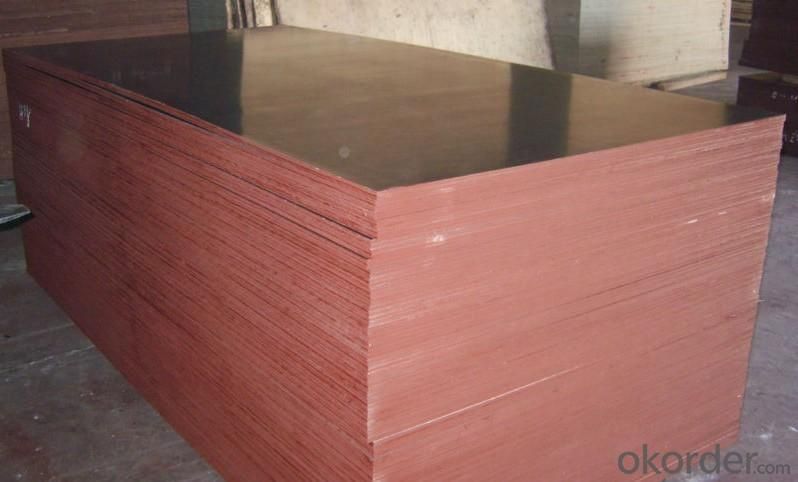

Finger Jointed Core Black Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Finger-jointed core film faced plywood (Brand: CPLEX)

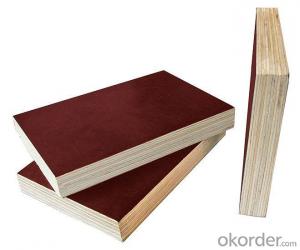

Product Name | Film faced plywood |

F/B | Black film, brown film,red film |

Grade | Construntion grade(one/two time hot press) |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | mealmine and WBP |

Thickness | 9-25mm |

Specification | 1220x2440mm, 1250x2500mm,915x1830mm |

Moisture Content | 8-10% |

Package | Standard export packing |

Press | one times press/two time press grade |

MOQ | 1x20GP |

Price Terms | FOB, CIF, CFR |

Payment | T/T 30%, irrevocable LC |

Delivery Time | Within 15 days after order confirmed |

Supply Capacity | 4500 cbc/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique; Credit first, fair trading |

Formaldehyde Emission Standards | E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg |

| Thickness(mm) | Layers | Standard size | Large size | ||

| min. (mm) | max.(mm) | min.(mm) | max.(mm) | ||

| 9 | 7 | 8.5 | 9.5 | 8.2 | 9.5 |

| 12 | 8 | 11.5 | 12.5 | 11.2 | 12.5 |

| 15 | 9-10 | 14.5 | 15.5 | 14.2 | 15.5 |

| 18 | 11 | 17.5 | 18.5 | 17.2 | 18.5 |

| 21 | 13 | 20.2 | 21.5 | 20.2 | 21.5 |

Features of FJ-FFP board:

1. Cheap. With lower price than normal FFP products

2. Environmental. Less cutting trees.

3. Life time: 1-3 times. Good to be used for not tall buildings like villa etc.

Tips: lower price will help customers to save their money in some of their projects.

Structure of FJ-FFP board:

12mm finger-jointed core + 4 fresh wood veneers

12mm thickness core is from the recycled plywood board. The used plywood will be cut into small pieces before reconstruction. The materials with defection will be picked off before it has been jointed into a core board. And then, to press 4 layers of fresh wood veneers to make a new core for 18mm film faced plywood.

Packaging & Delivery

1.Packaging Detail: loosing package,pallets package,all can according to customers'requirements

2.Delivery Detail: delivery within 10 days after get the deposit

Specifications

1.Usage:Decoration,Furniture,Construction.

2.Package:Inter packing:0.2mm plastic bag. Outer packing:Pallets are coverd with plywood or carton

3.Min order 1*20FCL or 23 cubic meter

4.Payment terms:L/C at sight,T/T 30% as deposit ,D/P.

5.Supply ability:6000 Cubic meter/month or 8000 pcs/day.

6.Main marke:Indonesia Malaysia India,Thariland,Middle East,Europe,Africa.

FAQ:

Q: Where are your main markets?

A: we are people-oriented company and our main markets are Southeast Asia, Middle East, South Africa, Russia, South America etc.

- Q:What does plywood mean and its synthesis?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q:What are the plywood specifications?

- International Organization for Standardization of ordinary plywood production, from the structure, finished product moisture content, quality 3 to make the provisions:

- Q:The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q:Distinguish between multilayer boards and plywood

- Plywood is one of the common materials for furniture, one of the three panels of man-made board, but also for aircraft, ships, trains, cars, construction and packaging materials.

- Q:What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q:What are the defects of the plywood?

- unsound section unsound knots The decaying part of a section of a child does not exceed 1/3 of the knot.

- Q:Selection of plywood in plywood production

- Artificial veneer is the use of relatively low prices of logs cut into veneer, made by a certain process pressure made of wood, and then cut into a beautiful pattern decorated veneer.

- Q:What is the best way to fix multi-layer plywood?

- The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q:How to use building plywood?

- Four types of plywood for the tide resistant plywood, used in the indoor normal, general purpose plywood with beech, linden wood, ash, birch, elm, poplar and so on.

- Q:What is the amount of construction works used for this plywood?

- A class of plywood for weather resistance, resistance to boiling water plywood, which and he has a durable, high temperature, the advantages of steam treatment;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Finger Jointed Core Black Film Faced Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords