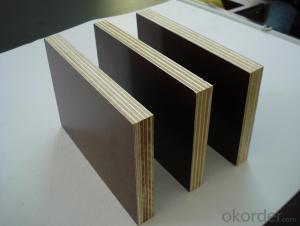

Film Faced Plywood Shuttering Plywood Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

| Film faced plywood | ||||||||

| No. | Item | Data | ||||||

| 1 | Size | 1220*2440,920*1830,1230*2440,as customer's requirments | ||||||

| 2 | Thickness | 2-30mm | ||||||

| 3 | Density | 600kg/cbm and up | ||||||

| 4 | Core | Poplar,Hardwood,Combi,ect | ||||||

| 5 | F/B | Plywood : Okoume,Keruing,Bintangor,Melamine,ect Construction plywood : Black/Brown/Red film or with logo | ||||||

| 6 | Glue | MR , E1 , E2 , WBP ,ect | ||||||

| 7 | Grade | BB/BB , BB/CC , CC/CC , CC/DD , ect | ||||||

| 8 | Tolerance | 0.5mm(+/-) | ||||||

| 9 | Moisture | 8%-12% | ||||||

| 10 | Package | Seaworthy Pallet Packing wirh plastic film wrapping on the inside | ||||||

| 11 | Usage | Furniture , Construction , Packing , ect | ||||||

| 12 | Delivery Time | Within 15-30days | ||||||

| 13 | Payment | T/T 30% or L/C at sight | ||||||

| 14 | Qty | 25cbm/1*20GP 55cbm/40HQ | ||||||

| 15 | Converyance | Qty/20gp : 8 PLTS Qty/40gp : 16PLTS Qty/40hq : 18PLTS | ||||||

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q:What are the plywood specifications?

- International Organization for Standardization of ordinary plywood production, from the structure, finished product moisture content, quality 3 to make the provisions:

- Q:How do you choose plywood in plywood production?

- but the overall furniture, wood is made of other wood, and now the store will be the furniture as "

- Q:Multilayer plywood with what method is fixed

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like materia

- Q:Ordinary plywood is divided into four categories

- Wood fiber or other plant fiber as raw material to be pressed into a density of 0.50 ~ 0.88g / cm3 plate

- Q:What is the type of plywood editing?

- In order to make full use of forest resources to develop plywood production, make the best use of our country's newly developed national standards (draft approval) according to the use of adhesive pull

- Q:The usual length and width specifications are:

- The main tree species are: camphor, willow, poplar, eucalyptus and so on. The main origin of plywood: Indonesia and Malaysia.

- Q:What are the further processing of plywood?

- Direct printing plywood Direct print plywood is printed directly on the plywood surface with simulated wood grain or other patterns.

- Q:Plywood is generally used in applications where the strength and stability of the material are relatively high

- It can be installed directly. It can be made of concrete frame structure and formwork.

- Q:Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Hard fiber board is also a density board, but its density is above 0.80g / cm3. Divided into one side of the light, the other side of the textured side of the hard fiber board and two-sided hard fiber board two.

- Q:defects are divided into four grades

- It is generally judged by visualizing the allowable defects on the plywood. The grade depends on the permissible material defects, machining defects, and the requirements for splicing

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Film Faced Plywood Shuttering Plywood Construction Plywood 18mm

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords