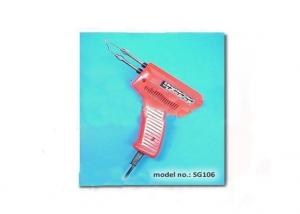

Ef Electrofusion Gas Fusion Welding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

gas fusion welding

suitable for butt fusion welding of plastic pipes and fittins made of PE,PP and PVDF.

Universal electro fusion processor

Electro Fusion Fitting system is electrically fusion jointing method that the gap between fitting and PE pipe is heated and melted by the means of resistance wires which are placed in the socket in the fitting. Each EF Sockets are controlled automatically by micro-processor and RMS value.

Features

All functions are designed for ease of operation.

The display is equipped with back-lighting. This will enable operator to work in poor lighting and at night

Depending on site, fusion number is automatically changed and stored (up to 10 site names). Inputting site name can continuously connect fusion number and perform work even when moving from site to site.

You can see fusion content using view function without printing. (Black mark at abnormal part)

The built-in printer uses thermal paper (safe for 5 years). Outputting 1 fusion result takes about 1.5 seconds.

Change quantity of output current per hour is divided into 10 sections for output, so that reliability on fused material may be enhanced.

Output capacity is designed as 3600W (@220Vac) in order to supply stable output.

The machine is equipped with a bar code reader of convenient CCD type, which can read at once.

Stable fusion becomes possible thru accurate control of output voltage (8-50±0.2Vac) at the input voltage even with high voltage jumps.

Universal fusion : resistor, barcode and manual.

Specification

Operating voltage |

AC86 to 264V |

Fusion voltage |

AC170 to 250V |

Output voltage |

AC8 to 50V ±0.2V |

Operating Temperature |

-23°Cto 49°C |

Dimension |

380(W)X320(D)X270(H) |

Weight |

21Kg |

Power consumed |

0.1Kw~3.6Kw |

Output current |

2A~80A |

Fusion data storage |

200 Times |

Fusion time |

10sec to 5999sec |

- Q:What kind of reinforcement is needed for 32MM steel bars on Railway overpasses, what kind of welding machine is preferred for welding machines, what brand is selected and what type?. Please help users answer, thank you very much

- Continuous flash welded barsMaximum diameter (mm)10~1212~1616~2020~25Preheat Flash Welded reinforcementMaximum diameter (mm)20~2232~36FortyType of welderUN1-50UN1-75UN1-100UN2-150 welding machine model determined the largest!!!The brand does not need to ask this question, the price is different, the brand is certainly different, the principle is same with the purchase electrical appliance!!

- Q:How to choose welding leakage current

- The working principle of the welding machine is different, and the requirements of the leakage protection are different.On the choice of welding leakage action current, we must first determine the working current, the working current can be calculated according to current / voltage = power calculation, calculate the working current of the welding machine, taking into account the characteristics of the welding work (a short time, the current instantaneous impact of large) choice, leakage current than the normal work some current. According to the calculated work current, select the appropriate leakage protector.Butt welding machine is also called current welder or resistance touch welder. By using the resistance between the two workpieces' contact surfaces, the contact surfaces of two mutually butted metal can be instantly heated, melted and fused instantaneously through a low voltage and high current.Simple to use welding machine and welding machine with similar method, welding transformer power supply special features, when the special transformer is in butt welding working resistance is very small, the amount of current limit, to ensure the normal welding current.Silicon controlled rectifier has been applied to the welding machine. New control methods have been produced, mainly for the more accurate current control and more reliable welding quality, but the basic principle and the calculation method of current are the same.

- Q:Transformer instability, resulting in a breakdown of a 11kw motor, welding machine can not work, our company is 200 independent transformers, power supply alone, how can I ask back?

- How do you know the reason for the transformer? If it is a transformer fault, is there any damage to your other equipment?

- Q:Thank you, find the answer!Senior fellow: for different grades of steel requirements with what electrode problems, I have learned. What I want to know now is whether there is any requirement for the power of the welding machine with different welding electrodes If there is, then this requirement is clear on the specification, or the actual operation of direct existence? If not, is that possible as long as the DC welder is available? For example, the site construction operation radius of 53m, then we have to choose more than 55m and tower type. Troublesome seniors!

- Specific requirements for you to see what the problem of choosing motor electrode, are required, what do you use for electrode current and what specific requirements, the electrode that has will help you choose what what current high current motor

- Q:380V 150KVA flash butt welder, what kind of cable do you need?

- The wire diameter is usually calculated according to the following formula:Copper wire: S= IL / 54.4UAluminum wire: S= IL / 34UIn style:I - the maximum current (A) passed through a wireL - the length of the wire (M)U - permissible power drop (V)S - cross sectional area of the conductor (MM2)So, you know what material and how long wires can be used to determine how much cable you want.

- Q:Leakage switch operating current 30mA can not meet the use of steel butt welder, how should I do?

- It is best to replace one, simply did not make it go without

- Q:Senior fellow: for different grades of steel requirements with what electrode problems, I have learned. What I want to know now is whether there is any requirement for the power of the welding machine with different welding electrodes If there is, then this requirement is clear on the specification, or the actual operation of direct existence? If not, is that possible as long as the DC welder is available? For example, the site construction operation radius of 53m, then we have to choose more than 55m and tower type. Troublesome seniors!

- Specific requirements for you to see what the problem of choosing motor electrode, are required, what do you use for electrode current and what specific requirements, the electrode that has will help you choose what what current high current motor

- Q:What welding machine is used for butt welding of stainless steel pipe?

- Zhongbang welding flash butt welding machine, without welding wire.

- Q:What is the reason that the welding band saw blade is not firmly used after two years of flash butt welding machine? How to solve?

- Check the electrode face of the welder. There is something wrong with it.

- Q:When the welding machine works, the contactor sends out a big arc. What is the cause of the main power supply trip?

- Power mismatchCoil short?Measuring input and output resistanceConnect a 1000 Watt lamp to the input to see if the input to output voltage is normal

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | 20.00% Western Europe 20.00% Mid East 20.00% South America 20.00% North America 10.00% Northern Europe 9.00% Southeast Asia 1.00% Central America |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Ef Electrofusion Gas Fusion Welding

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 10 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches