Tinplate Times

Tinplate Times Related Searches

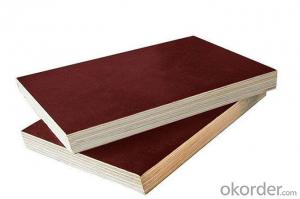

Black Melamine Faced Chipboard Tinplate Times FacebookHot Searches

Cost Of Plywood Per Square Metre Cost Of Plywood Waterproof Plywood Cost Cheapest Place To Buy Plywood Wholesale Plywood Prices Plywood Sheets Prices Cheapest Plywood Prices Melamine Faced Chipboard Suppliers Uk Local Plywood Suppliers Wholesale Glue Gun Price Philippines Wbp Plywood 18Mm Price Cheapest Place To Buy Plywood Wholesale Plywood Prices Plywood Sheets Prices Local Plywood SuppliersTinplate Times Supplier & Manufacturer from China

Okorder.com is a professional Tinplate Times supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Tinplate Times firm in China.Hot Products

FAQ

- Yes, tinplate can corrode over time. The tin coating on the steel surface of tinplate can gradually deteriorate due to exposure to moisture, acids, or other corrosive substances, leading to the formation of rust or corrosion.

- Yes, tinplate can be used for packaging confectionery products. Tinplate is a commonly used material for food packaging due to its durability, resistance to corrosion, and ability to maintain product freshness. It provides a safe and secure packaging option for confectionery items, ensuring a longer shelf life and preserving the quality of the products.

- Tinplate is generally considered more sustainable than plastic due to its recyclability and lower environmental impact throughout its life cycle. Unlike plastic, tinplate is easily and endlessly recyclable without any loss in quality, making it a preferred choice for packaging materials. Additionally, tinplate has a lower carbon footprint, as it requires less energy to produce and emits fewer greenhouse gases during manufacturing. On the other hand, plastic often ends up in landfills or as litter, taking hundreds of years to decompose and contributing to pollution and wildlife harm. Overall, tinplate offers better sustainability attributes and is a more environmentally friendly option compared to plastic.

- Tinplate contributes to the functionality of household goods by providing a durable and corrosion-resistant coating that protects the underlying material from damage and extends the lifespan of the product. Additionally, tinplate's ability to be easily molded into various shapes and sizes allows for the creation of intricate designs and structures, enhancing the aesthetics and functionality of household items.

- The main challenges in tinplate coating thickness control involve achieving uniformity and accuracy throughout the entire coating process. This requires overcoming issues such as variations in tinplate surface quality, ensuring consistent application of the coating material, and accurately measuring and monitoring the thickness of the coating. Additionally, maintaining control over the coating parameters and adjusting them appropriately to accommodate different tinplate grades and production conditions is also a challenge. Overall, achieving precise and consistent coating thickness control is crucial for ensuring product quality and meeting customer specifications.

- The common printing techniques for tinplate include lithography, screen printing, and digital printing.

- Tinplate is commonly used in the photography industry for the production of film canisters, which are used to store and protect photographic film. Its corrosion-resistant properties and ability to block out light make it an ideal material for preserving the quality of film. Additionally, tinplate is also used in the manufacturing of various photography accessories such as lens caps, lens hoods, and camera cases, providing durability and protection to photographic equipment.

- Tinplate is widely used in the electrical industry for various applications such as the production of electrical enclosures, transformer tanks, and terminal boxes. Its corrosion-resistant properties make it an ideal material choice to protect electrical components from moisture and other environmental factors. Additionally, tinplate is used for manufacturing electrical connectors, terminals, and busbars due to its excellent electrical conductivity.