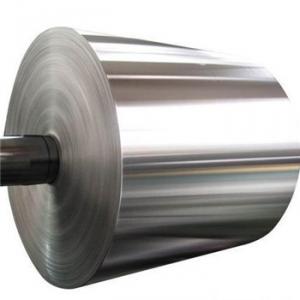

Aluminum Roll Stock

Aluminum Roll Stock Related Searches

Aluminum Stock Aluminum Block Stock Flat Stock Aluminum Roll Aluminum Flat Stock Rolls Aluminum Foil Stock Aluminum Rod Stock Aluminum Mill Stock Aluminum Price Stock Aluminum Raw Stock Aluminum Metal Stock Aluminum Box Stock Aluminum Frame Stock Aluminum Ak Stock Aluminum Rifle Stock Aluminum Gun Stock Us Aluminum Stock Aluminum Commodity Stock Aluminum Lathe Stock Raw Aluminum Stock Stock Aluminum Ball Aluminum Stock American Aluminum Stock Aluminum Round Bar Stock Round Aluminum Stock Buy Aluminum Stock Aluminum Stock Price Aluminum Key Stock Aluminum Machining Stock Aluminum Fuel Rail Stock Aluminum Square StockAluminum Roll Stock Supplier & Manufacturer from China

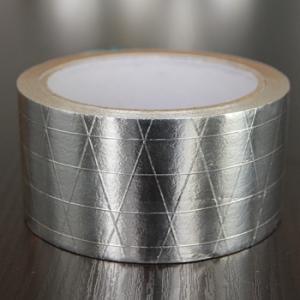

Aluminum Roll Stock is a versatile material that encompasses a variety of aluminum sheets and coils, available in different alloys, thicknesses, and finishes. These products are widely recognized for their excellent corrosion resistance, lightweight properties, and high strength, making them suitable for a broad range of applications. In various industries, aluminum roll stock is utilized for manufacturing purposes, including construction, automotive, aerospace, and packaging, among others. Its adaptability and durability have positioned it as a go-to choice for numerous applications, from architectural components to intricate mechanical parts.The usage scenarios for aluminum roll stock are vast, as it can be tailored to meet specific requirements in terms of size, shape, and surface finish. For instance, in the construction sector, it is commonly used for facades, roofing, and structural components due to its strength and weather-resistant properties. In the automotive industry, aluminum roll stock is employed in the production of lightweight vehicle parts, contributing to improved fuel efficiency and reduced emissions. Additionally, its non-toxic nature makes it an ideal material for food and beverage packaging, ensuring the safety and preservation of the contents.

Okorder.com stands out as a prominent wholesale supplier of aluminum roll stock, boasting a comprehensive inventory that caters to the diverse needs of customers across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminum roll stock they provide meets the highest industry standards. Their extensive selection and competitive pricing make them a reliable choice for businesses looking to source this essential material for their production processes.

Hot Products